Iceviolet

Active Member

Hello, I am going to be attempting to restore a 1973 280CE. This will be my first full-on restoration project.

The main goal of the project is to end up with a solid and reliable everyday classic, finished to a high standard. I am not chasing perfection or trying to restore the car to win any concourse events. I simply want a good looking, well maintained, usable classic that can be driven!

My background is mechanical engineering and I am sound with the mechanical aspects of restoration and have experience of engine swaps etc. However I have never attempted bodywork or chassis restorations before on any scale. A few small patch repair jobs here and there but nothing major. So my main ambitions for the project are to develop my skills and become competent at repairing/making /welding sheet metal body panels and preparing the body work for paint and finishing. Time will tell!

I have made a start, but progress has been slow and most likely will be going forward as I have a 6 month old now in the equation and the missus has only just started to allow me back to my man cave for a few hours!

I plan to keep it as original as possible but I do want to change the colour of the car.

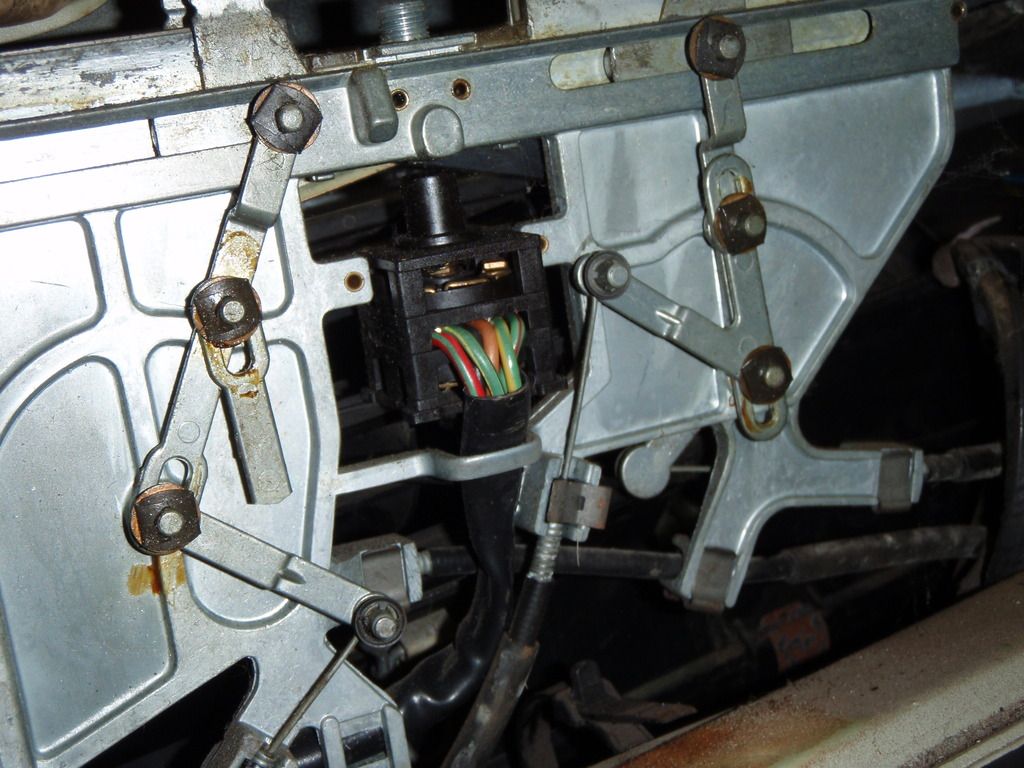

Also I cant decide whether or not to keep the D-Jet or go for a more modern system like Megasquirt. I need to look more into the pros and cons for this.

A few progress shots so far:

The main goal of the project is to end up with a solid and reliable everyday classic, finished to a high standard. I am not chasing perfection or trying to restore the car to win any concourse events. I simply want a good looking, well maintained, usable classic that can be driven!

My background is mechanical engineering and I am sound with the mechanical aspects of restoration and have experience of engine swaps etc. However I have never attempted bodywork or chassis restorations before on any scale. A few small patch repair jobs here and there but nothing major. So my main ambitions for the project are to develop my skills and become competent at repairing/making /welding sheet metal body panels and preparing the body work for paint and finishing. Time will tell!

I have made a start, but progress has been slow and most likely will be going forward as I have a 6 month old now in the equation and the missus has only just started to allow me back to my man cave for a few hours!

I plan to keep it as original as possible but I do want to change the colour of the car.

Also I cant decide whether or not to keep the D-Jet or go for a more modern system like Megasquirt. I need to look more into the pros and cons for this.

A few progress shots so far: