Hi All,

As some of you may be aware there is a new 77mm Supercharger pulley (twin bearing) available from MSL and manufactured via UPD. It offers the ability to match the power / torque figures of the tried and tested 180mm crank pulley and as such, potentially offers owners a new pulley to purchase over and above the existing 83/84mm clutched SC pulley and the various crank pulleys and fixed pulleys.

So, does it work.......

In order to test the pulley we decided to use the same car (mine) and ran it in 3 states of set up;

1) Stock (OEM supercharger pulley)

2) Euro-charged 83mm supercharger pulley (X pipe fitted in place of secondary cats and resonator removed)

3) As above with 77mm Supercharger pulley

See below a picture of the 3 different pulleys, with from left to right - the new 77mm pulley, the 83mm Euro-charged pulley and the standard OEM Supercharger pulley;

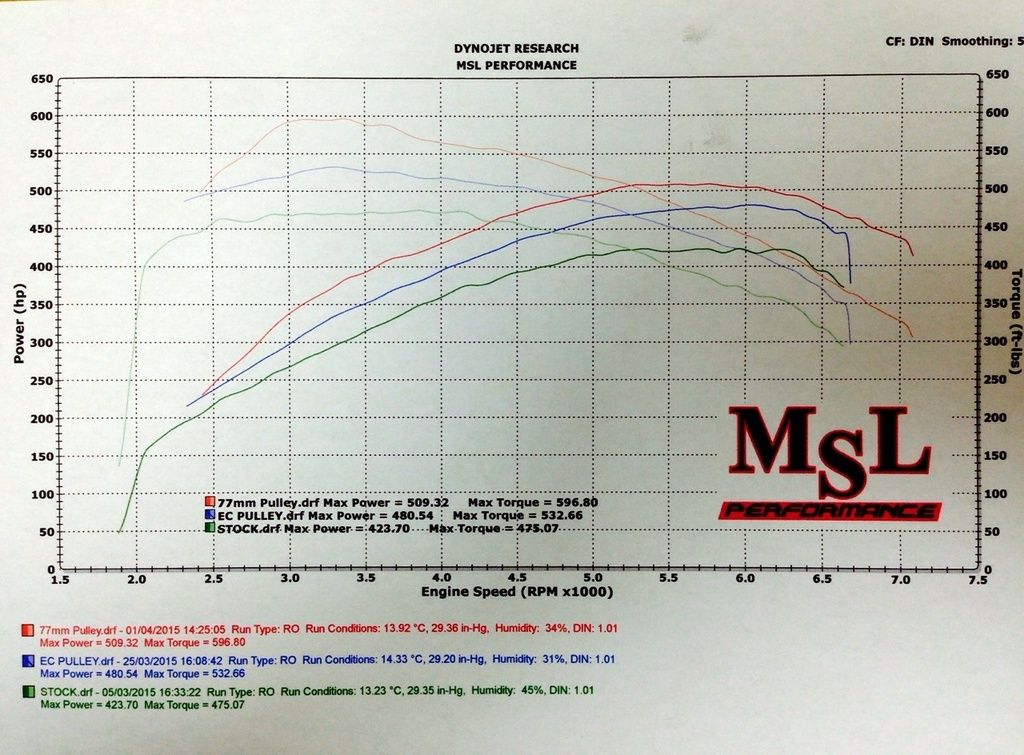

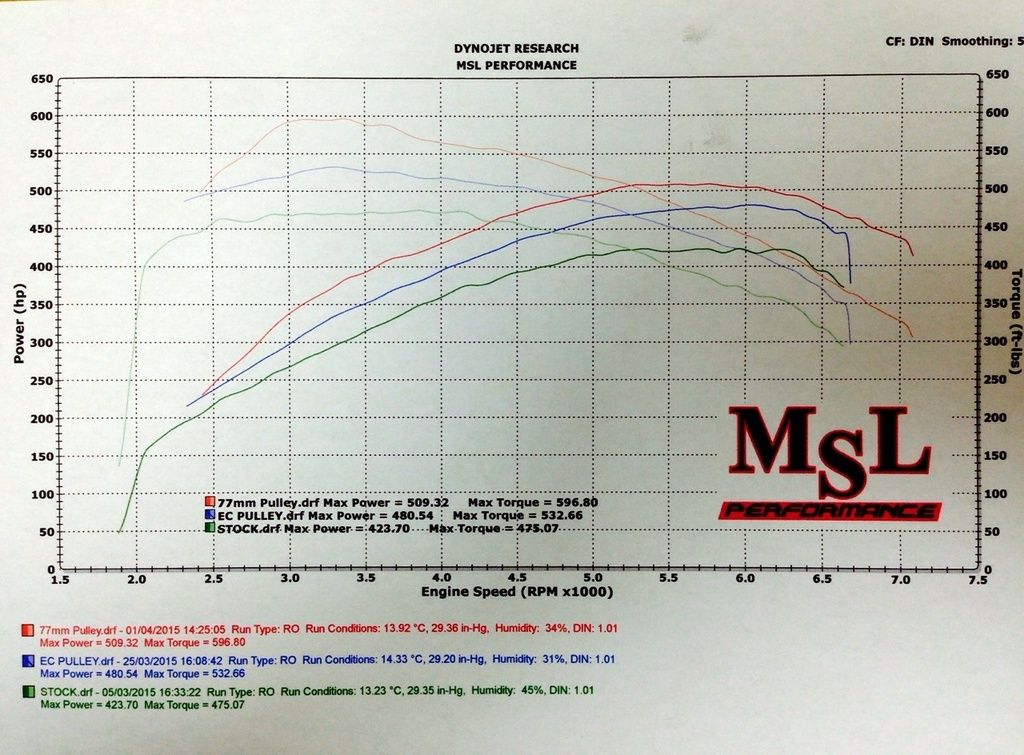

The power and torque figures at the wheels were as follows (flywheel in brackets);

1) Stock - 423.7bhp / 475lb/ft (500 / 561)

2) 83mm -480.5bhp / 532.66lb/ft (567 / 629)

3) 77mm -509.3bhp / 596.80lb/ft (601 / 704)

Whilst the actual numbers may not be that important, the incremental gains are absolutely clear to see. Acid / Sarim at MSL took care to ensure that the dyno runs were set up as close as possible for each run as the runs for each of the 3 stages of tune were done on different days, however what we did do was do a test on each day to ensure the numbers obtained previously were accurate and give or take 2-5bhp, they were.

The Map

With regard to the map supplied by John@BFT@MSL then at the moment with the limited driving I have done it is spot on, there may be more refinement to come but the way the car drives it feels great. The AFR trace was spot on but IAT's as expected were slightly higher than the previous pulley, this is not surprising given that the supercharger is being worked harder, yet the numbers delivered speak for themself. Going forward with this upgrade it is almost a necessity to look at additional cooling, with a starting point being to split the cooling, other options around Killer Chillers and Ice tanks would certainly generate lower IAT's and provide quicker cooling in spirited driving. I currently have no additional cooling apart from a recently fitted Johnson CM30 IC pump, the car still pulls like a train but I am sure if I tried to sustain repeated runs then it would affect peak power and torque delivery. In normal driving though I have no complaints...

The fitting of the pulley is identical to the EC pulley, the only difference being I opted for a Gates 8PK1255 belt (smaller) to accommodate the smaller pulley dimension.

So how does it drive?

The difference between each stage is very clear. The responsiveness is the most noticeable aspect and with the 77mm pulley the response is instant, the low down torque is fantastic with part throttle enough to send the car flying down the road. It is certainly a worthwhile upgrade that takes the car to the next level of performance. The map feels fine and if anything the car drives better than previous.

So what more can I say.......

A big thanks to Acid, Sarim & John and the team at MSL. Especially for asking me to be the guinea pig, of which I was more than happy to oblige. To date and apart from the one Guy in the US running this pulley I see no other updates yet on the US Forums, so hats of to Acid for moving quickly and getting this installed with a map to deliver the results.

Acid currently has these on offer so check his thread in this section of the Forum. If you are thinking of a supercharger pulley then my advice would be to consider this one. If you have an existing EC SC pulley and are tempted.......then do it

To be fair it's a great situation for a 55k owner to have. There is now the tried and tested EC Supercharger pulley, which as we know and can see from the graph makes great gains and requires few other mods and now this 77mm pulley.

I'll post future updates to let you know how the car performs and the robustness of the pulley etc. please feel free to post any questions on here as I am sure myself or Acid will answer them.

Cheers

Jules.

As some of you may be aware there is a new 77mm Supercharger pulley (twin bearing) available from MSL and manufactured via UPD. It offers the ability to match the power / torque figures of the tried and tested 180mm crank pulley and as such, potentially offers owners a new pulley to purchase over and above the existing 83/84mm clutched SC pulley and the various crank pulleys and fixed pulleys.

So, does it work.......

In order to test the pulley we decided to use the same car (mine) and ran it in 3 states of set up;

1) Stock (OEM supercharger pulley)

2) Euro-charged 83mm supercharger pulley (X pipe fitted in place of secondary cats and resonator removed)

3) As above with 77mm Supercharger pulley

See below a picture of the 3 different pulleys, with from left to right - the new 77mm pulley, the 83mm Euro-charged pulley and the standard OEM Supercharger pulley;

The power and torque figures at the wheels were as follows (flywheel in brackets);

1) Stock - 423.7bhp / 475lb/ft (500 / 561)

2) 83mm -480.5bhp / 532.66lb/ft (567 / 629)

3) 77mm -509.3bhp / 596.80lb/ft (601 / 704)

Whilst the actual numbers may not be that important, the incremental gains are absolutely clear to see. Acid / Sarim at MSL took care to ensure that the dyno runs were set up as close as possible for each run as the runs for each of the 3 stages of tune were done on different days, however what we did do was do a test on each day to ensure the numbers obtained previously were accurate and give or take 2-5bhp, they were.

The Map

With regard to the map supplied by John@BFT@MSL then at the moment with the limited driving I have done it is spot on, there may be more refinement to come but the way the car drives it feels great. The AFR trace was spot on but IAT's as expected were slightly higher than the previous pulley, this is not surprising given that the supercharger is being worked harder, yet the numbers delivered speak for themself. Going forward with this upgrade it is almost a necessity to look at additional cooling, with a starting point being to split the cooling, other options around Killer Chillers and Ice tanks would certainly generate lower IAT's and provide quicker cooling in spirited driving. I currently have no additional cooling apart from a recently fitted Johnson CM30 IC pump, the car still pulls like a train but I am sure if I tried to sustain repeated runs then it would affect peak power and torque delivery. In normal driving though I have no complaints...

The fitting of the pulley is identical to the EC pulley, the only difference being I opted for a Gates 8PK1255 belt (smaller) to accommodate the smaller pulley dimension.

So how does it drive?

The difference between each stage is very clear. The responsiveness is the most noticeable aspect and with the 77mm pulley the response is instant, the low down torque is fantastic with part throttle enough to send the car flying down the road. It is certainly a worthwhile upgrade that takes the car to the next level of performance. The map feels fine and if anything the car drives better than previous.

So what more can I say.......

A big thanks to Acid, Sarim & John and the team at MSL. Especially for asking me to be the guinea pig, of which I was more than happy to oblige. To date and apart from the one Guy in the US running this pulley I see no other updates yet on the US Forums, so hats of to Acid for moving quickly and getting this installed with a map to deliver the results.

Acid currently has these on offer so check his thread in this section of the Forum. If you are thinking of a supercharger pulley then my advice would be to consider this one. If you have an existing EC SC pulley and are tempted.......then do it

To be fair it's a great situation for a 55k owner to have. There is now the tried and tested EC Supercharger pulley, which as we know and can see from the graph makes great gains and requires few other mods and now this 77mm pulley.

I'll post future updates to let you know how the car performs and the robustness of the pulley etc. please feel free to post any questions on here as I am sure myself or Acid will answer them.

Cheers

Jules.

Last edited: