Nasco12

Active Member

The engine in question is a 111.945 (2l)

Here goes:

https://flic.kr/p/S5qLKJ

https://flic.kr/p/S5qLKJ

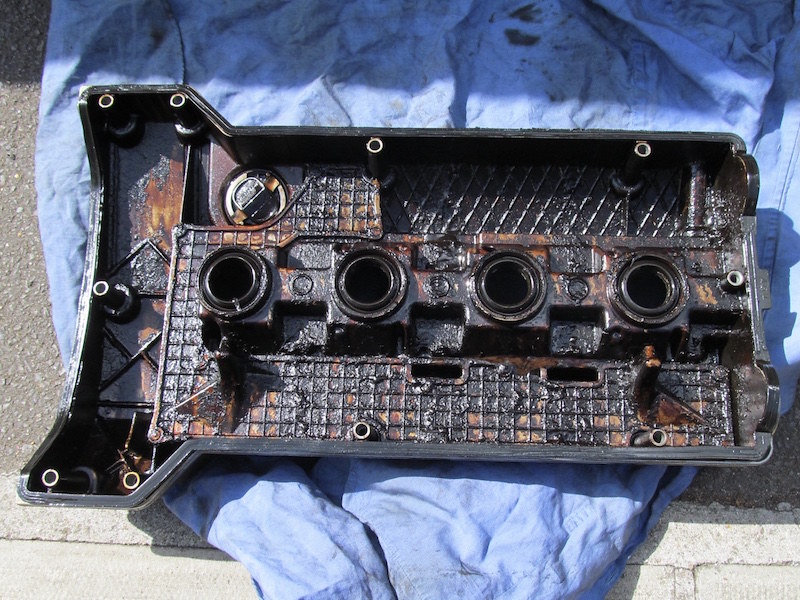

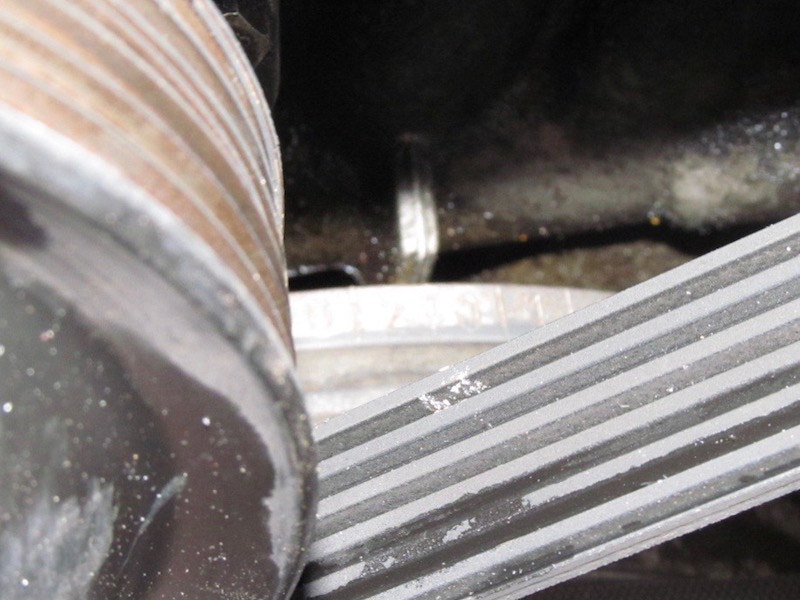

Undertray removed. The grime may well be the result of the oil escaping past the head gasket.

https://flic.kr/p/SLWDxd

https://flic.kr/p/SLWDxd

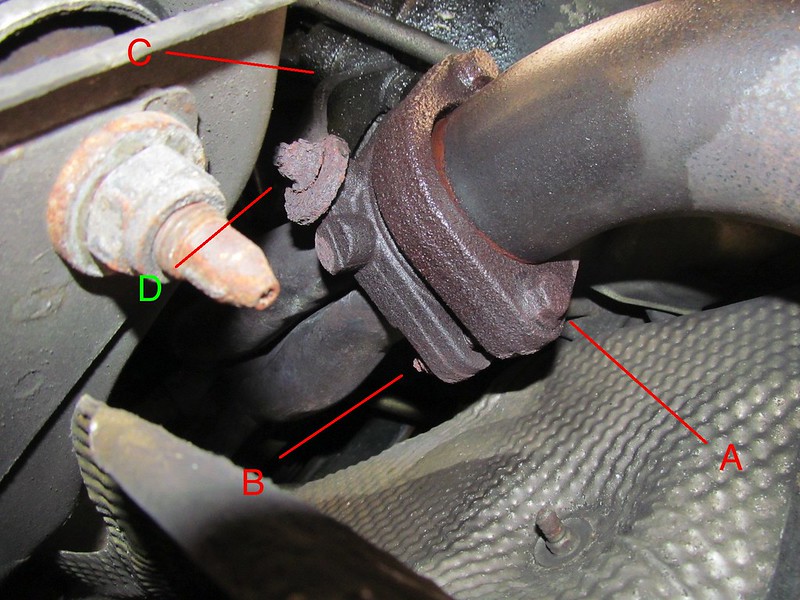

And we’re stuck. I can’t get the exhaust manifold bolts out. According to the Haynes manual it does have to come off because the manifold stretches all the way down to the transmission. I have tried a nut splitter and a chisel (both subsequent to taking this photo).

https://flic.kr/p/S618HE

https://flic.kr/p/S618HE

The solution as I understand it is usually heat. As the car is currently parked at the side of the road I am rather reluctant to get out a blow torch. Even if managed to avoid setting passers-by alight it might be alarming for some. Access for a hacksaw is poor.

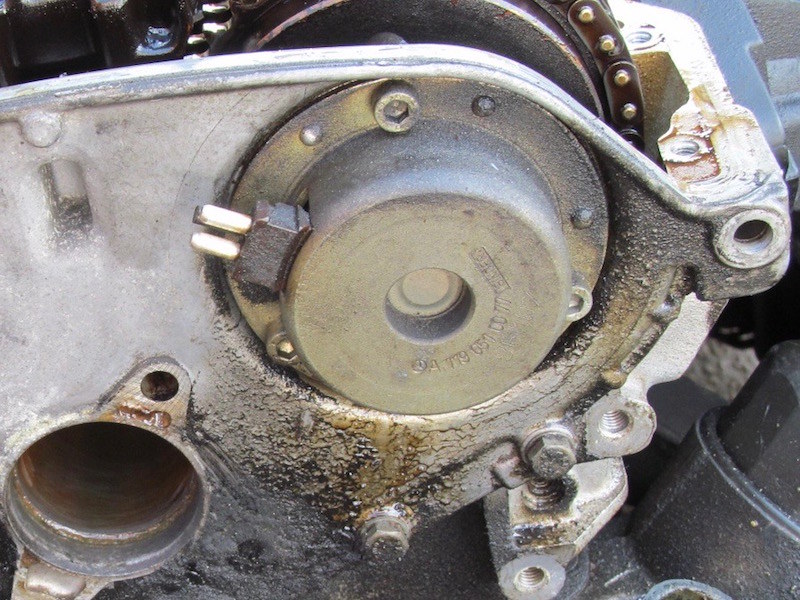

The one bit of good news is that I have been able to locate the block coolant drain plug. I was beginning to think it was something of a myth.

Here goes:

Undertray removed. The grime may well be the result of the oil escaping past the head gasket.

And we’re stuck. I can’t get the exhaust manifold bolts out. According to the Haynes manual it does have to come off because the manifold stretches all the way down to the transmission. I have tried a nut splitter and a chisel (both subsequent to taking this photo).

The solution as I understand it is usually heat. As the car is currently parked at the side of the road I am rather reluctant to get out a blow torch. Even if managed to avoid setting passers-by alight it might be alarming for some. Access for a hacksaw is poor.

The one bit of good news is that I have been able to locate the block coolant drain plug. I was beginning to think it was something of a myth.

Last edited: