Ian B Walker

MB Enthusiast

- Joined

- Jun 7, 2003

- Messages

- 7,668

- Location

- Freckleton

- Car

- 300-24, saloon and coupe, E300 24 valve diesel estate

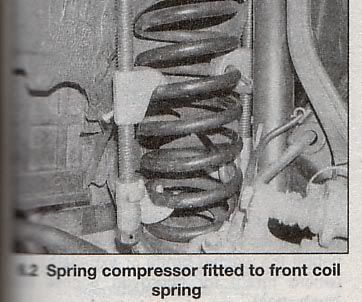

I'm with you there Howard. I have done a spring change on a W124 and believe me, the tension has to be seen to be believed. I would NEVER consider a spring change on any car that I work on without the right compressor. I have a likeing for my head and other body parts