RaceDiagnostics

Active Member

Went through leads 1 to 7 and there was a very percievable drop in rpm when pulled off. On cylinnder 8, only a virtually impercievable change.

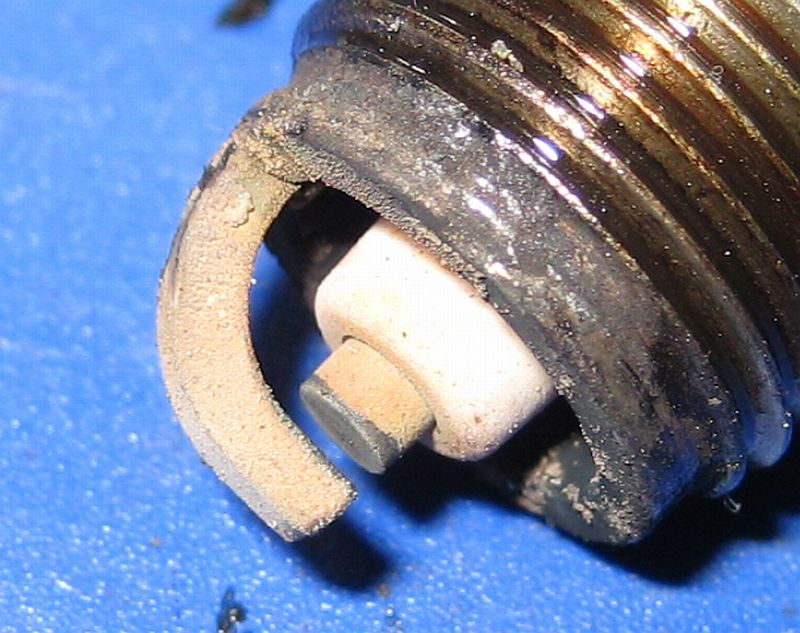

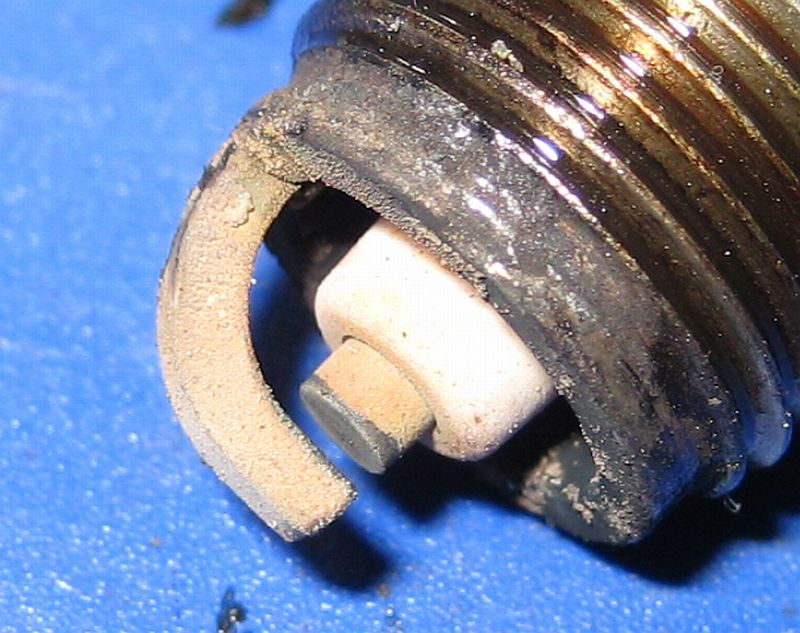

Checked leads, ok, and pulled out the plug, it looks ok, see below.

Next I went in search of a colourtune plug I bought 25 yeas ago but couldn't find it.

I wonder if it could be being starved of fuel, I'm not sure how the fuel injection works on the 450SL, any suggestions?

I'll try to get hold of a new colourtune plug tomorrow and see if there is a flame.

Checked leads, ok, and pulled out the plug, it looks ok, see below.

Next I went in search of a colourtune plug I bought 25 yeas ago but couldn't find it.

I wonder if it could be being starved of fuel, I'm not sure how the fuel injection works on the 450SL, any suggestions?

I'll try to get hold of a new colourtune plug tomorrow and see if there is a flame.