Bellow

Hardcore MB Enthusiast

There are three holes at exact intervals on the flywheel edge, so no problem with the 36:2 pattern - but I wonder if the fact they go all the way through the edge will cause an issue?

Presumably, the sensor develops a magnetic field of finite depth (reach) and a hole deeper than said reach wouldn't have any adverse effect but an overly shallow hole may.

How deep all the holes can be may be limited by encroachment on holes for securing clutch cover plate.

Very careful advance planning of hole diameter and spacing required I think to avoid weakening clutch holes. Also, if a bolt is present where a void should be - then the signal input will be lost.

Presumably (again, as this is mere guesswork) the holes have to have sufficient diameter to present a clean 'cutting' edge. Contrast with straight 'cutting' edges of teeth. Until a drill bit appears that can drill a square hole, then circular holes they must be.... I would though, study the ideally formatted toothed wheel and crib the solid:space ratio as closely as possible.

and doesn't address the issue of the shape of "tooth edge" unfortunately

and doesn't address the issue of the shape of "tooth edge" unfortunately

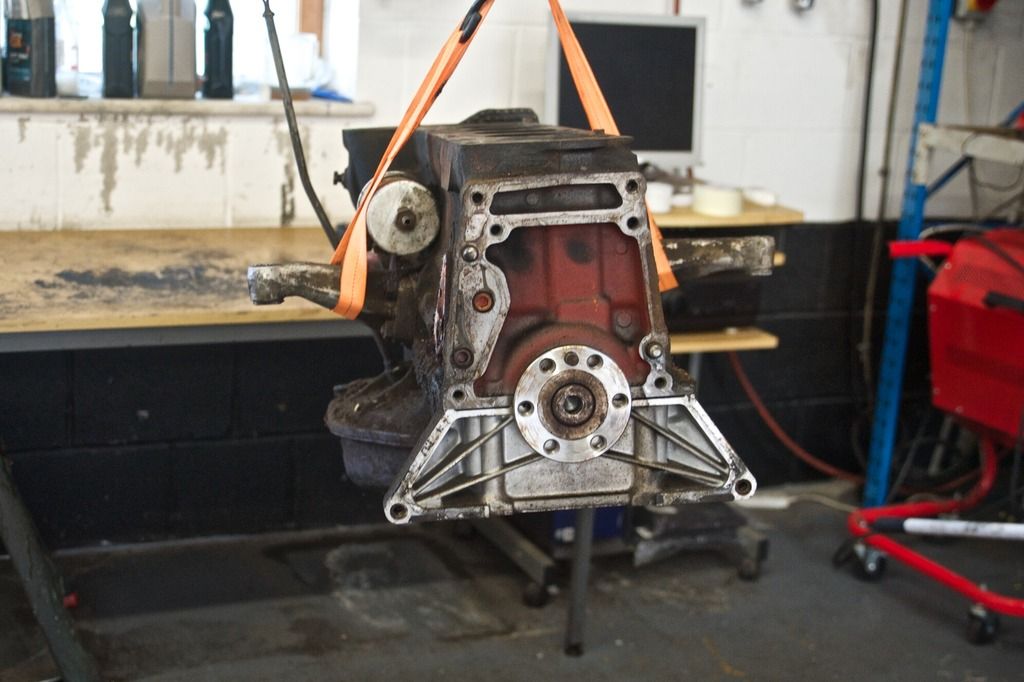

I am more and more drawn to the conclusion that the use of crank pulley mounted machined trigger wheel with suitable position sensor is the safest solution. Without the existing presence and position of a cps getting things positioned correctly and machining the flywheel is going to be fraught.

I am more and more drawn to the conclusion that the use of crank pulley mounted machined trigger wheel with suitable position sensor is the safest solution. Without the existing presence and position of a cps getting things positioned correctly and machining the flywheel is going to be fraught.

There was a comparison done on a Saab site where a guy machined the holes in a flywheel himself with a drill but later abandoned the idea in favour of a fabricated gap wheel with accurately machined slots.

There was a comparison done on a Saab site where a guy machined the holes in a flywheel himself with a drill but later abandoned the idea in favour of a fabricated gap wheel with accurately machined slots.