harry_lalli

Member

- Joined

- Dec 29, 2009

- Messages

- 58

- Location

- Birmingham, UK

- Car

- 2012 C63 Estate | 1972 W115 220/8 - White | 2000 VX220 2.2 Supercharged

Afternoon,

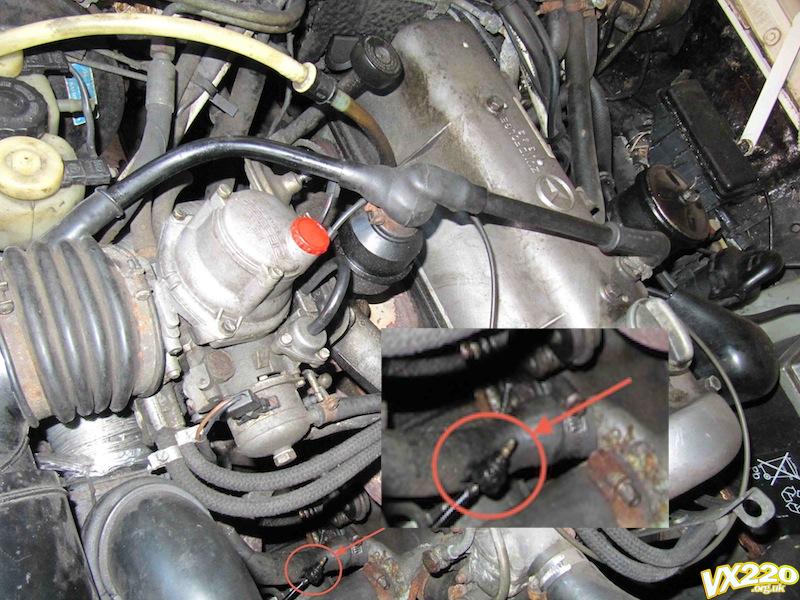

i have a question about the carb currently in my '72 W115. Its a pierburg/stromberg carb (175 CD)...but the accelerator pedal stick to the floor when fully pressed. Just wonderng whether there should be a return spring as it seems to come up ok when lifting it by hand....not the wisest thing to do whilst driving though

have only had the car a few months, been getting some welding done, only just noticed...

any ideas? if it is a return spring, any ideas whether its available as part of some refurb kit? don't really want to resort to using elastic bands

Thanks people

i have a question about the carb currently in my '72 W115. Its a pierburg/stromberg carb (175 CD)...but the accelerator pedal stick to the floor when fully pressed. Just wonderng whether there should be a return spring as it seems to come up ok when lifting it by hand....not the wisest thing to do whilst driving though

have only had the car a few months, been getting some welding done, only just noticed...

any ideas? if it is a return spring, any ideas whether its available as part of some refurb kit? don't really want to resort to using elastic bands

Thanks people