grober

MB Master

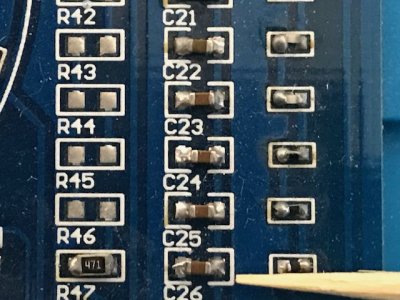

Part of the problem lies with the "infantilisation" of customers and dare I say it service agents departments by keeping service and repair information proprietary/ secret. This aided by a heavy dependance on smart electronic circuitry [cheap to mass manufacture once designed but difficult to emulate/repair in the event of failure] Thus manufacturers create a dependancy culture to generate an additional product revenue stream to purchase price and encourage replacement rather than repair. Sealed for life is another ploy whereby repair is made difficult by devices held together or encapsulated by adhesive or sealant. In todays world of diminishing natural resources perhaps governments need to legislate against these commercially driven "throw away culture" designs?