crownhouse

New Member

A W215 CL500 ABC HYDRAULIC SYSTEM SERVICE / REPAIR I’LL NEVER FORGET

I got an enquiry for the refurbishment of a (2006) W215 CL500 ABC Hydraulic System a couple of months back.

The owner wanted the following work done:

• Full Hydraulic System Bleed with 15 litres of Pentosin CHF11s

• Replacement of all Hydraulic Filters (ABC & Power Steering)

• Replacement of all Accumulators

• Refurbish of Rear Hydraulic Valve Block

• Refurbish of Front Hydraulic Valve Block (due to height drop when parked)

All the parts were sourced by the owner directly from Mercedes Benz and I provided the Hydraulic Seal Ring Kit for the job at hand.

A date was arranged and the owner drove down 200 miles from Leeds to the workshop in Oxford. The service / repair of the hydraulic system started at 0900 hrs (9am) and was completed at 1900 hrs (7pm).

Workshop was prepared, tooling ready, vehicle available, new original parts, we made our introductions, customer settled down for the period and the work started.

The hydraulic system had not been worked on before so it should have been a straight forward service / repair.

This was my job plan:

• Remove all required underbody panels

• Spray all connectors with penetrating anti-seize oil

• Flush hydraulic system with new CHF11s

• Remove and replace ABC micron filter

• Remove and replace power steering filter

• Disconnect and replace rear accumulator

• Disconnect and refurbish rear valve block

• Replace pressure accumulator

• Refit rear valve block

• Test rear system of ABC

• Disconnect refurbish front valve block

• Replace front accumulator

• Refit front valve block

• Test front system of ABC

• Test and top-up entire ABC system

• Replace all removed underbody panels

. . . and job done!

However, things often do not work out as planned

Workshop Bay and Tooling ready for the service / repair

Section for hard tooling (Dismantling)

Section for Soft Tooling (Assembly)

2006 W215 CL500 Silver / Black Leather AMG Factory Body Kit

M113 V8 Engine, Boot open ready for ABC Hydraulic Fluid Flush

On inspection of the hydraulic fluid, I discover that the condition, purity and cleanliness of the oil (CHF11s) is well above average condition. I then advice the owner that a flush of the system will not be required at this stage. Filters will be changed, accumulators replaced, valve blocks refurbished and after four to six months of use, the system can then be flushed with another new set of filters.

Old filters removed (long one for the ABC suspension, short one for power steering)

New filters to go in with specially ordered valve block solenoid o-rings in background

Two large Impact accumulators and a small rebound accumulator waiting installation

Rear section of exhaust uncoupled to provide easier access to rear accumulator

Rear of car showing exhaust drop after uncoupling

Rear accumulator removed showing feed pipe.

Oil showing on parts prior to removal, is deep penetrating anti-sieze oil to aid dismantling of nuts, bolts, connections and fixings.

Rear valve block removed showing only hydraulic pipes

Dismantled valve block showing height adjustment and shut off solenoids

Shut off solenoids showing deterioration of seals and washers

Height adjusting solenoids showing deterioration of seals and washers[/B

At this stage I measured the ride heights and requested the owner to take the car for a 15 min drive to warm up the hydraulic fluid and on return to check again for leaks and any visible drop in ride height. Again results were excellent.

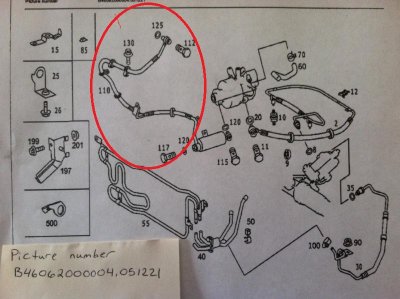

Now that the rear had been taken care of, I proceeded to the front of the car to service and repair the front valve block assembly which was leaking internally and causing the front suspension to drop after being parked and over a few hours.

Front valve block in the process of being removed

All the hose connections came off without any problems and the front valve block assembly was brought to the work bench for dis-assembly. Brackets, fixings and attached rebound accumulator which takes up the impact (compression) shock for the front suspension all came off easily too.

The height adjusting solenoids twisted off and detached from the aluminium valve body without any issues.

The shut off solenoids were the last to be detached. The left shut off solenoid was very stiff, but it eventually detached as it should. However, the right shut off solenoid refused to budge.

The owner of the car had come down to the workshop and was watching the dis-assembly procedure and witnessed the problem that had now reared its head.

Dry cloths were used to grip and attempt to turn the solenoid to its detaching position but it would not turn. Clamps were used and still it would not turn. The good old vice was applied but still the solenoid would not turn and detach. Witnessing the efforts and failed attempts of the solenoid removal, the owner asked if he should purchase a new valve block, it was that serious.

After an hour of failed attempts, I decided that since I had a spare shut off solenoid at hand, I would saw (cut) off the stuck solenoid so as to remove it from the aluminium valve block. It was apparent to the owner that there was no other remedy so I was given the go ahead to exercise this emergency surgery procedure.

Using a thin blade disc and an air drill, the solenoid was cut off and I was able to remove the entire solenoid without any damage or scaring to the aluminium valve block.

Sawn (chopped) shut off solenoid

(Phone battery had run dead and this was not the time to recharge so unfortunately pictures stopped)

The ABC hydraulic system reservoir was filled (slightly above max point) to compensate for hydraulic loss and air gaps and the system was started and primed. There were no leaks and the suspension worked perfectly, raising and lowering and maintaining its ride height. Hydraulic fluid levels were topped up to the required quantities and mark and all the under body panels were securely bolted.

The W215 CL500 had undergone major surgery but the outcome was good.

Car and owner are presently back in Leeds and all four AMG 19” wheels are being professionally cleaned, skimmed and polished.

Thanks for reading.