Hi guys

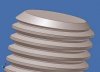

I have standard oem 18' Mercedes alloys and I have just fitted 15mm spacers at the rear and I need a bit of a confidence boost on the length of the bolts I have used.

The originals have 27 mm of thread and engage with 6.5 turns. I have bought new 40mm bolts which engage very slightly under 6 turns (say 5.8 turns).

Do youse think this will be ok or not or am I being a bit paranoid?

Cheers

I have standard oem 18' Mercedes alloys and I have just fitted 15mm spacers at the rear and I need a bit of a confidence boost on the length of the bolts I have used.

The originals have 27 mm of thread and engage with 6.5 turns. I have bought new 40mm bolts which engage very slightly under 6 turns (say 5.8 turns).

Do youse think this will be ok or not or am I being a bit paranoid?

Cheers