Gizzardio

New Member

Hi

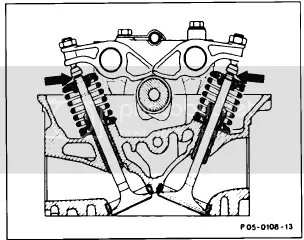

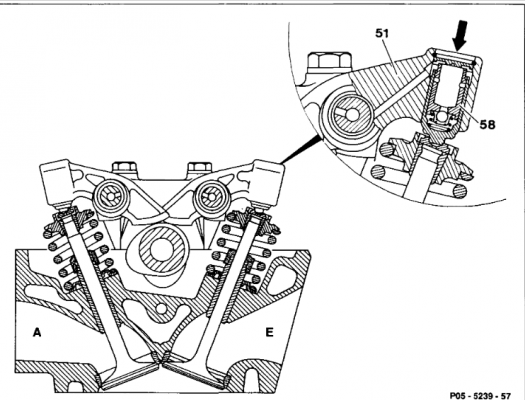

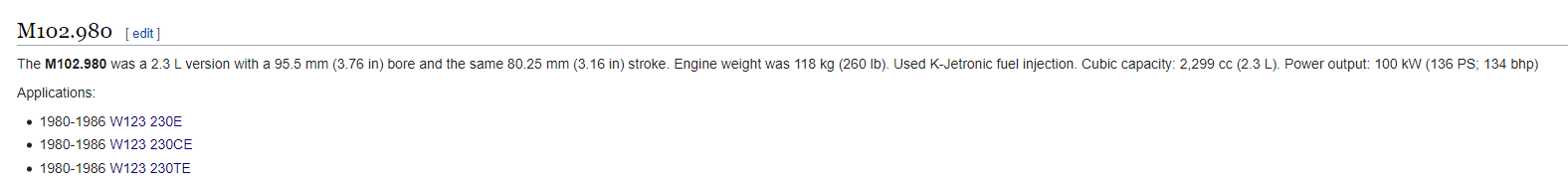

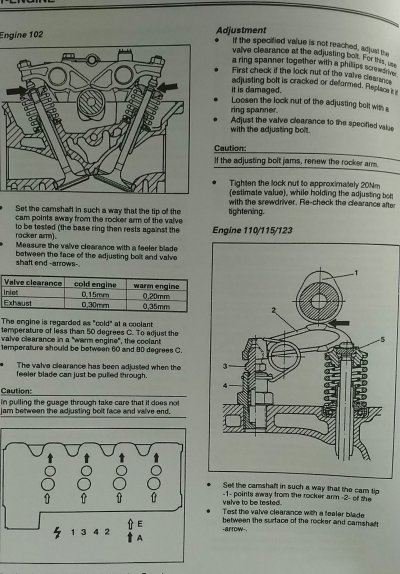

I had to replace my rocker / valve cover gasket and thought whilst I was in there I'd check the valve clearances on my 1983 W123 230CE. I believe the engine reference is M102.980. It's the 2.3 litre in that model anyway. The service manual I have found shows the valve clearance values on cold engine for inlet and exhaust as 0.15mm and 0.30mm respectively. So I went in the feeler gauges but I can't understand where this gap should be. In the manual it shows the location as between the rocker arm underside and the top of the valve spring cap. But there is no gap here at all even with my smallest feeler gauge. It feels like there wouldn't be a gap there as the spring is pushing under compression up onto the rocker arm in any position of the cam. Any ideas what I should be looking for here?

Thanks

I had to replace my rocker / valve cover gasket and thought whilst I was in there I'd check the valve clearances on my 1983 W123 230CE. I believe the engine reference is M102.980. It's the 2.3 litre in that model anyway. The service manual I have found shows the valve clearance values on cold engine for inlet and exhaust as 0.15mm and 0.30mm respectively. So I went in the feeler gauges but I can't understand where this gap should be. In the manual it shows the location as between the rocker arm underside and the top of the valve spring cap. But there is no gap here at all even with my smallest feeler gauge. It feels like there wouldn't be a gap there as the spring is pushing under compression up onto the rocker arm in any position of the cam. Any ideas what I should be looking for here?

Thanks