Iskapsts

Member

Hi guys, I’ve probably rushed and messed up injector bolt thread in valve cover at 2nm only , from what I learned now I didn’t clean the injector hold down screw bore and stripped thread

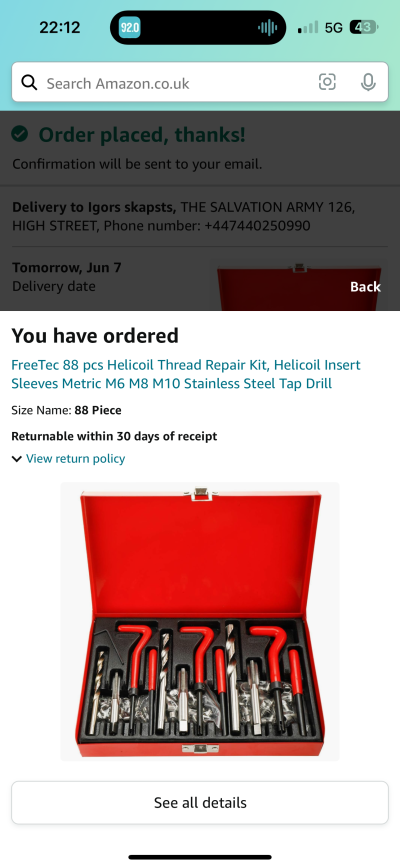

I’ve got heli coil set as only option in my view in attempt to get it done.

I’ve never done it before(taping)

Any suggestions, recommendations,

How much nm torque even these heli coils can hold?

Regards Igors

Attachments

Last edited: