Good day all,

I am in need some expert brake pipe advice on how to fix a broken brake pipe on ML270 2003 RHD

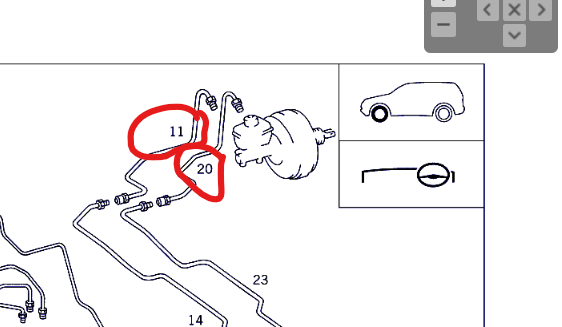

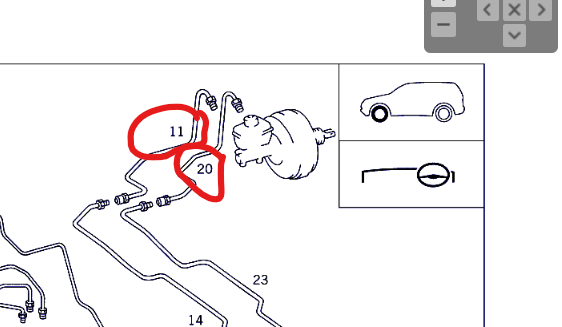

Pipe 11 (diag below)has corroded through where it meets the union with 14.

I am reasonably confident i can split the union without damaging 14 however I cant seem to find the part number or any reference to the replacement part.

Plan b is to make it from a kit.

So I have 2 questions, looking for your kind support :

1) any ideas on the part number for 11 and where i can buy it from.

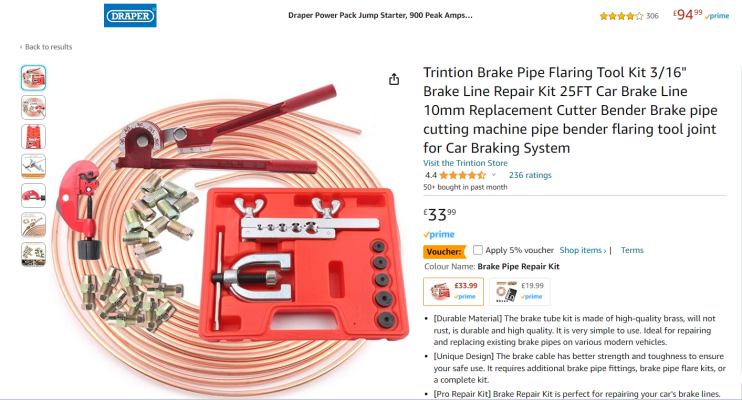

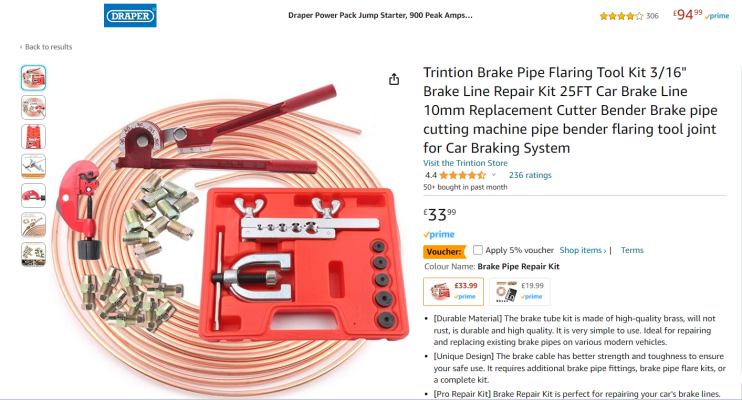

2) if making it myself i think this is kit ( link and image) has the right size pipe and connections. (noting the lower mail union is v v corroded.)

Any other tips guidance greatfully received

I am based near Winchester and local garages are saying 3 weeks minium to book me in to get it done, indicating they are not that interested.

thanks in advance

I am in need some expert brake pipe advice on how to fix a broken brake pipe on ML270 2003 RHD

Pipe 11 (diag below)has corroded through where it meets the union with 14.

I am reasonably confident i can split the union without damaging 14 however I cant seem to find the part number or any reference to the replacement part.

Plan b is to make it from a kit.

So I have 2 questions, looking for your kind support :

1) any ideas on the part number for 11 and where i can buy it from.

2) if making it myself i think this is kit ( link and image) has the right size pipe and connections. (noting the lower mail union is v v corroded.)

Any other tips guidance greatfully received

I am based near Winchester and local garages are saying 3 weeks minium to book me in to get it done, indicating they are not that interested.

thanks in advance