OK so the garage got back to me:

a) codes were all erased

b) test drove the car.. after 10 mins or so the EML came back on. Symptoms now the same as before

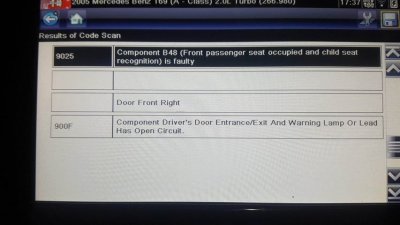

c) ran diagnostics again... image attached showing errors.

Not sure what the door one is (possibly just the kerb light or something?), but the occupancy sensor I know is to do with the passenger seat having a dodgy wire or sensor (when someone's in the passenger seat the SRS warning disappears, otherwise if seat is empty it stays on) - just havn't got around to fixing that yet.

Other one (not shown in photo below) is of course the CPS: p0336 no signal crank sensor

View attachment 74506

He's quite convinced it's to do with the wiring from the sensor to the ECU, but says that given the state the sensor is now in (covered in electrical tape and cable ties!) due to the Indy buggering it up, the sensor will obviously need changing anyway because it's now too physically fragile (and of course exposed to the elements!).

So now I'm basically back to where I was previously. He can attempt to remove it with engine/gearbox where it should be (will obviously need to remove driveshaft to gain access as there's not enough space to swing a cat otherwise), but if no luck it's going to be an engine and box out job, to knock it out from inside the bell housing... then replace the slave cylinder (and while he's there it makes sense to change the clutch/ plate at the same time).

Ultimately it's going to depend what he quotes me as to whether or not I get him to go ahead with it and attempt to remove it, and then another quote for if it goes pear-shaped and him having to drop the engine/box. At least then I'll have best-case/worst-case numbers to mull over.

Parts, cost-wise I'm looking at £270 for a 3pc LUK clutch kit.. but (hopefully I'm wrong?) if I'm having him do the clutch, is it wrong to not do the DM flywheel while he's there?

If it wasn't so costly (just shy of £600 for the DMF alone, and very difficult to get a hold of one from anywhere I've tried, anytime soon) I wouldn't even be considering cutting this corner.. but for a car worth £2k-ish that's a hell of a lot of dingo dollars!

Or my other option is to get the car back, carry on paying for it until October (would cost too much in fees to pay it off early) then sell it for spares or scrap and in the meantime carry on renting a car or go and lease one. Although I'd be out of pocket considerably, in the long-term this doesn't bother me

too much as I'm self-employed and will claim it back as an expense.. but short term it's a lot of money to be spending each month to effectively hire a car, and continue paying for one that's going to Mercedes heaven once it's paid off.

We may also get the W245 back from the dealership soon but have no idea when exactly.. could be a couple of weeks or it could be dragged out for more months.

I guess I'll see what this garage quotes for repair of the 169 first and take it from there.

In the meantime, any opinions on the DMF would be appreciated?

Cheers