Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

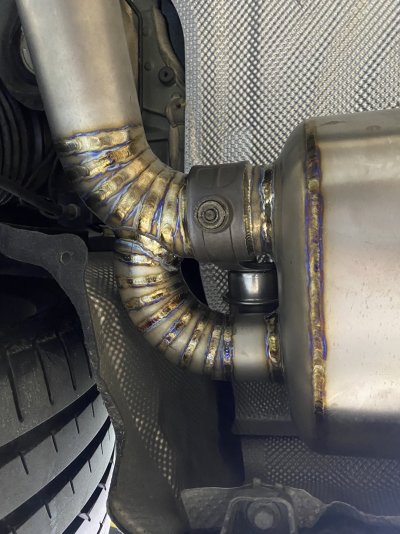

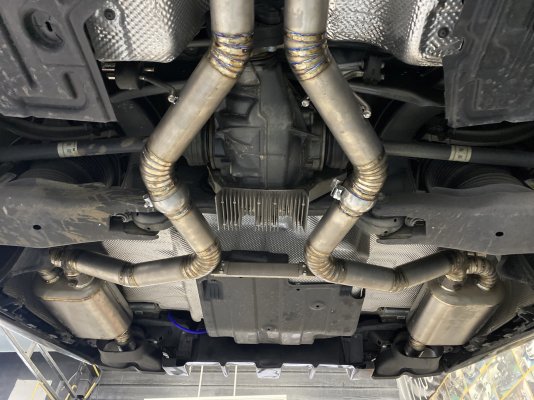

New Titanium Exhaust getting installed

- Thread starter ndwgolf

- Start date

kcsun

Active Member

Just asking not trying to start any arguments...........

Would it not be better to use some form of pipe bender rather than all that welding?? would have made a smoother route through the inside of the exhaust for the gas to flow freely??

kc

Would it not be better to use some form of pipe bender rather than all that welding?? would have made a smoother route through the inside of the exhaust for the gas to flow freely??

kc

Allan AMG

Active Member

- Joined

- Jun 9, 2016

- Messages

- 302

- Car

- W204 C63 Coupe

Why are there so many welds? Do they not have tube bender? With so many welds just increasing the chance of a failure. It will sound worse when it's blowing all over the place.

Kcsun beat me to it

Kcsun beat me to it

ndwgolf

Active Member

Atavus beat me to it,,It’s because it’s titanium. Doesn’t respond well to bending.

Allan AMG

Active Member

- Joined

- Jun 9, 2016

- Messages

- 302

- Car

- W204 C63 Coupe

Ti can be bent easily with the right equipment. There are hundreds of off-the-shelf pre-bent pipes available.

I had one made for a bike back in the 90's and since then the technology has well moved on.

I had one made for a bike back in the 90's and since then the technology has well moved on.

ndwgolf

Active Member

I don’t think so mate. I am 100% sure if there was an easier/cheaper way to do it then they would do that.. there is over 4 days of welding already……….time is money.Ti can be bent easily with the right equipment. There are hundreds of off-the-shelf pre-bent pipes available.

I had one made for a bike back in the 90's and since then the technology has well moved on.

If you google titanium exhausts and look at the pictures 95% are full of welds like what i have posted above……Go figure

ndwgolf

Active Member

Petrol Pete

Hardcore MB Enthusiast

Hydro forming is the best choice for Titanium tubes, but one for the specialists. The parts would be much stronger than what we see here as each weld is a potential leak/weak point even if the actual weld itself is stronger than the materiel it is the area around the weld that is a potential weak point. That is one of the reasons I mentioned purge welding (and high quality materials tubes/gas/filler etc) in my previous posts.

If the OP's exhaust has not been purge welded it will most likely fail , particularly in high stress areas.

If the OP's exhaust has not been purge welded it will most likely fail , particularly in high stress areas.

ndwgolf

Active Member

Allan AMG

Active Member

- Joined

- Jun 9, 2016

- Messages

- 302

- Car

- W204 C63 Coupe

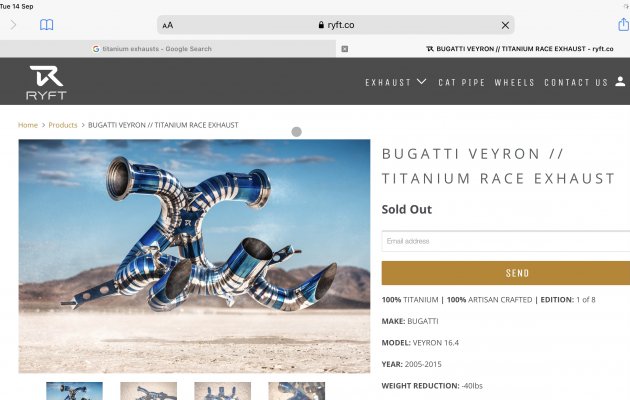

That was not the best example pic to use, look at that complex shape. I am talking about the run-of-the-mill 90°, 60°, 45° bends on a straight bit of pipe.I’m sure if there doing it on a $5m Bugatti then they will do it on a measly $230k E53 Benz

ndwgolf

Active Member

I'm no engineer but I'm trying to figure out where all that stress is coming from. It's basically an open ended pipe that is mounted on rubber bushings........ With a bunch of hot air blowing out of it............. Am I right or am I missing something?If the OP's exhaust has not been purge welded it will most likely fail , particularly in high stress areas.

- Joined

- May 10, 2006

- Messages

- 10,505

- Location

- Preston, Lancs

- Car

- S204 C220CDi Sport ED125 (Mr) Kia Picanto Domino 1.1 (Mrs)

Love the fact that it's Sold Out!I’m sure if there doing it on a $5m Bugatti then they will do it on a measly $230k E53 Benz

2View attachment 118447

Petrol Pete

Hardcore MB Enthusiast

Heat cycles and vibration.I'm no engineer but I'm trying to figure out where all that stress is coming from. It's basically an open ended pipe that is mounted on rubber bushings........ With a bunch of hot air blowing out of it............. Am I right or am I missing something?

Petrol Pete

Hardcore MB Enthusiast

There will be colour change , but basically wasted as no one will see it . Shame really.

Well, aren't you the ray of sunshine...

Petrol Pete

Hardcore MB Enthusiast

^^^ Just stating the facts. the colour change will not be spectacular BTW , not enough heat.

ndwgolf

Active Member

The idea of getting Titanium rather than SS or any other kind of metal was because I liked the sound it makes over the others. Seeing it change colours never crossed my mind as it's hidden away under the carThere will be colour change , but basically wasted as no one will see it . Shame really.

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)