- Joined

- May 17, 2010

- Messages

- 3,557

- Car

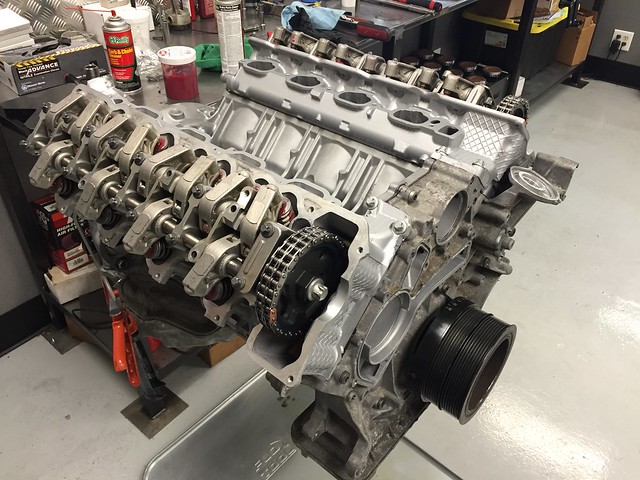

- S65, CLK5.6TT (WIP) & RRS 5.0 SC

Thought I'd do a thread on my car. Most of it is done now and I can start documenting the progress. I set out to build a Mercedes that can go over 200mph on a runway. The project is still pretty much work in progress so whether I succeed remains to be seen but that was the goal anyway. I must add that I haven't had a clue of what I'm getting myself into, otherwise I would have never started, but all this is history now. Enough for the intro, let's go.