Access isn’t an issue however the option the Kenny offered seems to be the way to go. My only concern with using an alloy filler in the hole is the concentrated heat. I’ve tried looking to see what’s behind the case and whether it will distort or if there’s anything that will melt. The current hole is now slightly off centre and has been drilled out at 5.5mm which is why when I tapped it out the M6 bolt was loose.Everything here depends on your personal experience and skill when it come to 'Helicoil' thread repair (Helicoil in inverted commas because it is a brand name , like Hoover') .

I (myself) would have a go at it at home having spent years drilling , tapping and 'Helicoiling' (is that a word ?) stuff , but I can well understand if someone else would be less keen to take the plunge.

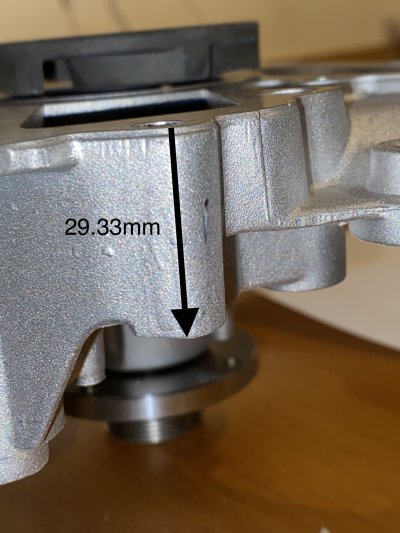

Drill size to tap M6 is 5.25 and for a Helicoli the drill has to be 6.3 then the Helicoil tap cuts slightly wider. Based on your photo you may run out of meat where the rubber gasket seal is on the casting.

Access could be an issue to actually get the thread insert tool in there to wind the new thread in. a 90' battery drill might be required , I can't tell from this photo.

It's a pain in the A$$ , but defiantly repairable.

I may have a go at “Helicoiling” on some scrap metal while I wait.

cheers