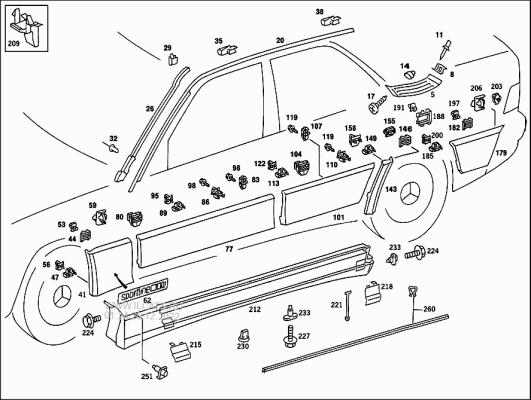

Recently bought a 1993 190D and the screws/bolts that attach the lower side panels and the mudflaps are so rusted that they are just formless blobs. Do I ask someone to drill them out? What else attaches the panels? What will I need to reattach them?

W201 190D bottom panel removal

- Thread starter Andrewalt

- Start date