Your advice sought...

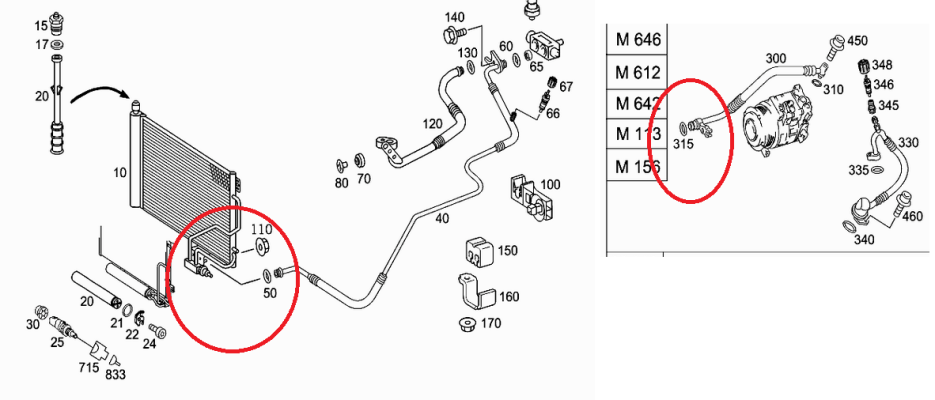

I've traced an AC leak to the condenser. The system is now empty, so I'm replacing the condenser/dryer. Unfortunately, I've hit a snag. While almost every nut & bolt has eventually decided to co-operate, the final connection of the refrigerant pipes into the base of the condenser/dryer refuses to come apart. The nut (item 110 in the diagram) came off easily enough, but the clamping block (next to 315) remains stubbornly locked onto the thread of the stud welded into the condenser. I suspect it's because the stud looks like steel, and the clamp is aluminium. I've tried the usual assortment of release agents (Crack-It, Freeze-Yer-Nuts-Off, Penetrating oil etc) to no effect. I'm unwilling to try the blowtorch just yet as the area is now covered in light oil and aerosol propellant, and is very close to plastic shrouds and the fan control module. Brute force is out due to the lack of space & the delicate nature of the condenser.

Anyone have any suggestions for undoing 18 years of aluminium corroding into steel?

It's particularly frustrating as it appears the MB changed the design at some point to permit the AC condenser to be replaced from below without having to dismantle the front end.

thanks,

Ian.

I've traced an AC leak to the condenser. The system is now empty, so I'm replacing the condenser/dryer. Unfortunately, I've hit a snag. While almost every nut & bolt has eventually decided to co-operate, the final connection of the refrigerant pipes into the base of the condenser/dryer refuses to come apart. The nut (item 110 in the diagram) came off easily enough, but the clamping block (next to 315) remains stubbornly locked onto the thread of the stud welded into the condenser. I suspect it's because the stud looks like steel, and the clamp is aluminium. I've tried the usual assortment of release agents (Crack-It, Freeze-Yer-Nuts-Off, Penetrating oil etc) to no effect. I'm unwilling to try the blowtorch just yet as the area is now covered in light oil and aerosol propellant, and is very close to plastic shrouds and the fan control module. Brute force is out due to the lack of space & the delicate nature of the condenser.

Anyone have any suggestions for undoing 18 years of aluminium corroding into steel?

It's particularly frustrating as it appears the MB changed the design at some point to permit the AC condenser to be replaced from below without having to dismantle the front end.

thanks,

Ian.