Hi,

After many months I have gotten round to removing a broken one and will be installing a used tailgate lift motor. Before I want this one to last so I need to make sure it is lubed properly.

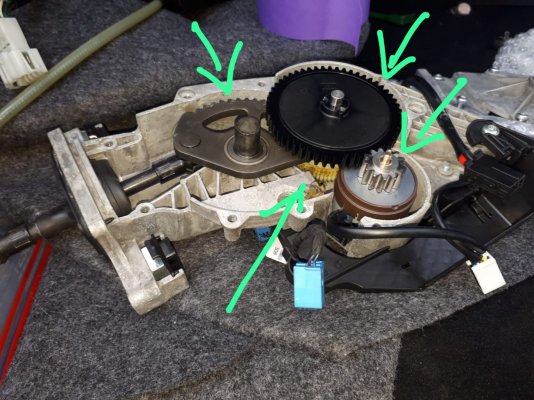

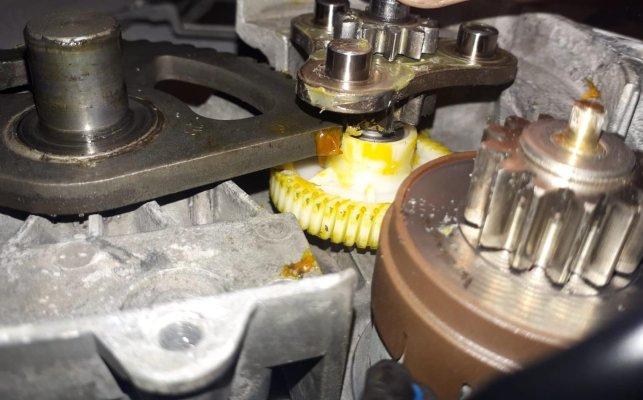

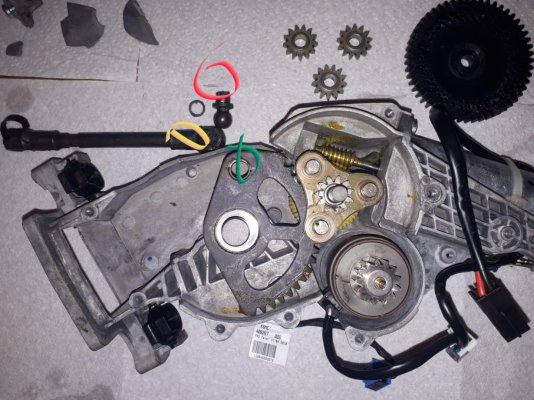

If you look at the photo- There is a metal and plastic gear on top which seems like it has never been lubed or should not be? There is the main gear with window regulator type teeth which has a light smear of some grease dating back to its manufacture in 2012. And underneath there is a little white cog with some old yellow looking oilyness on it.

For the longevity of the mechanism, which lubrication should I use where?

Thanks for listening,

D.

After many months I have gotten round to removing a broken one and will be installing a used tailgate lift motor. Before I want this one to last so I need to make sure it is lubed properly.

If you look at the photo- There is a metal and plastic gear on top which seems like it has never been lubed or should not be? There is the main gear with window regulator type teeth which has a light smear of some grease dating back to its manufacture in 2012. And underneath there is a little white cog with some old yellow looking oilyness on it.

For the longevity of the mechanism, which lubrication should I use where?

Thanks for listening,

D.