BigDusty

Active Member

Hi all,

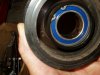

The bearing in the clutch which is attached to the kompressor is now sitting on my desk in front of me and is in bits, in other words the clutch bearing is knackered.

Rang up the stealership and to no surprise they informed me that I have to replace the whole of the kompressor as they don't sell the clutch separately.

As I type I stare at this bearing and I think to myself "something not quite right here, for the sake of replacing a £20 bearing it's now going to cost £1000 for a part that I don't need. What's next, one new gearbox when that clutch wears out!!

Looking on the web I did find a company in the USA that sells a bearing with the exact description and measurements to mine, thing is, it's to replace the bearing for the clutch on an airconditioner, but will it work??

http://bearingsdirect.com/products/...110&prevaction=category&previd=56&prevstart=0

So I once more turn to my trusty companions for help and advice to see if there is a sensible way to repair or replace the clutch on my kompressor.

Regards

BigD

The bearing in the clutch which is attached to the kompressor is now sitting on my desk in front of me and is in bits, in other words the clutch bearing is knackered.

Rang up the stealership and to no surprise they informed me that I have to replace the whole of the kompressor as they don't sell the clutch separately.

As I type I stare at this bearing and I think to myself "something not quite right here, for the sake of replacing a £20 bearing it's now going to cost £1000 for a part that I don't need. What's next, one new gearbox when that clutch wears out!!

Looking on the web I did find a company in the USA that sells a bearing with the exact description and measurements to mine, thing is, it's to replace the bearing for the clutch on an airconditioner, but will it work??

http://bearingsdirect.com/products/...110&prevaction=category&previd=56&prevstart=0

So I once more turn to my trusty companions for help and advice to see if there is a sensible way to repair or replace the clutch on my kompressor.

Regards

BigD

Last edited: