Update: After a long period, I am providing more information about the tuning.

Unfortunately, the

2260VKLR turbo isn't an ideal choice for several reasons:

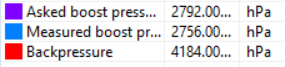

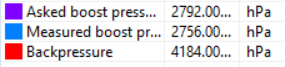

First, it generates a significant amount of

backpressure. With the same exhaust configuration on Stevie's car, we observed a

difference of 700 to 800 mbar in backpressure while maintaining the same boost pressure on the intake side. We even reached

4700 mbar backpressure while trying to make

2,1 bar boost as the 2365 turbocharger.

In fact, running the same pressure as the

OM642LS version already reaches the

maximum allowable backpressure for the engine. Unfortunately, the

hot side is too small.

During testing on my car—with a

straight-pipe exhaust from both exhaust exits (which flows significantly better than a single-exit pipe)—only

1.8 bar of boost resulted in

4200 mbar of backpressure. This was with a

straight-pipe exhaust and a 3" downpipe.

This exhaust :

Regarding its

spooling capabilities, I wasn't able to make it spool significantly earlier than the stock

2056 turbo. In theory, it should, but the best I managed was reaching

2 bar boost around 1900-2000 rpm on the CLK.

It should be capable of achieving

1.6 bar at 1600 RPM in the

stock LS configuration. However, the issue lies in

boost pressure management within the

EDC16 ECU, which, for some reason, does not allow the pressure to build as quickly as it should.

This leads to the next problem:

constant overboost at partial load. With

stock PID settings and the

VNT preposition map, the

2260VKLR turbo remains in a state of continuous overboost.

While driving at

110 km/h, the

overboost was consistently around

300 mbar higher than the target pressure. In theory, this should reduce fuel efficiency, but based on my measurements, that hasn’t been the case.

When attempting to lower the

VNT preposition to prevent the

VNT vanes from closing too much, I managed to

reduce the overboost. However, when the engine increased load

without increasing RPM—specifically while climbing a hill—the

boost pressure failed to follow the target increase, resulting in

underboost. In this condition,

fuel efficiency dropped significantly.

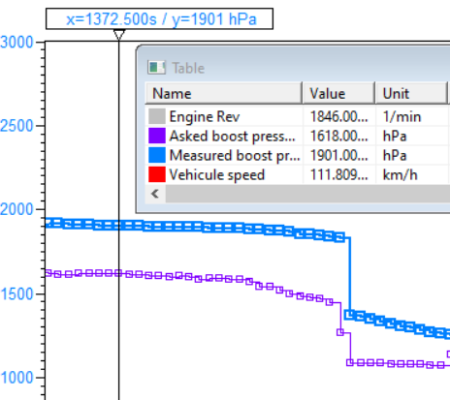

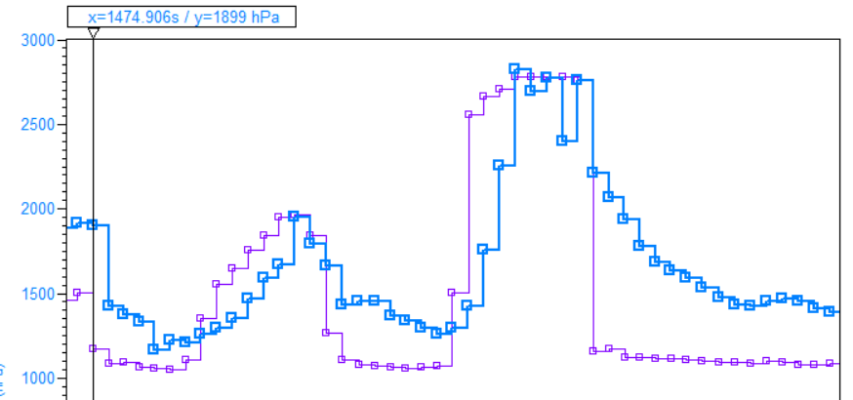

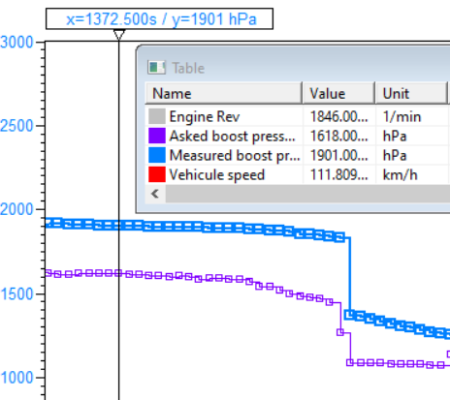

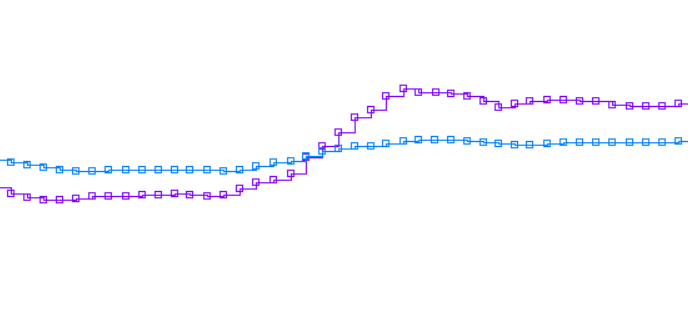

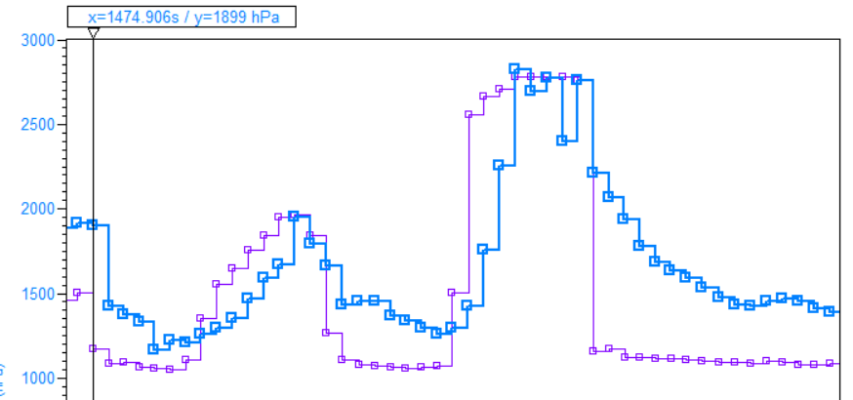

You can see this in the picture: the

purple curve represents the

target pressure, while the

blue curve shows the

measured boost pressure. The

VNT did not move correctly to follow the boost target desipite no PID has been modified.

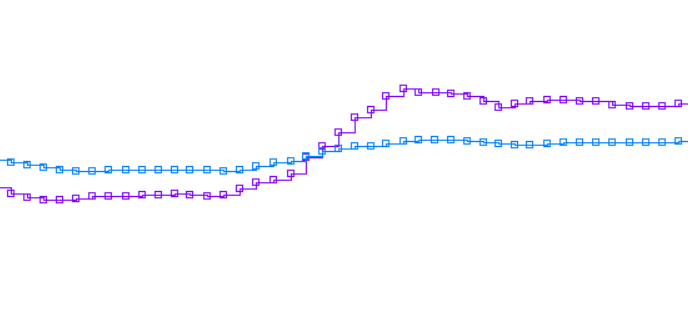

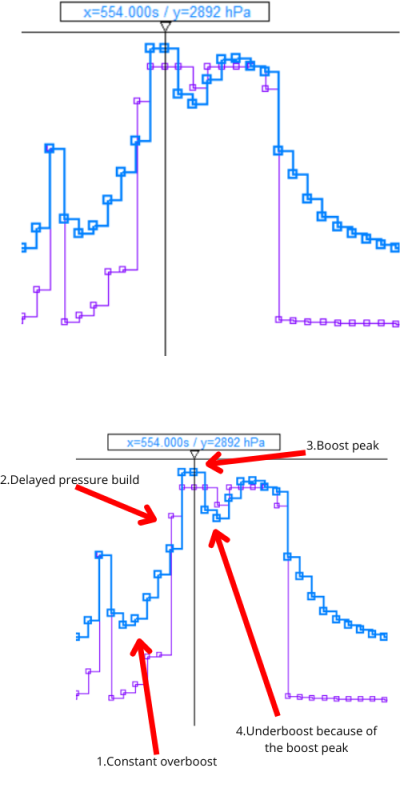

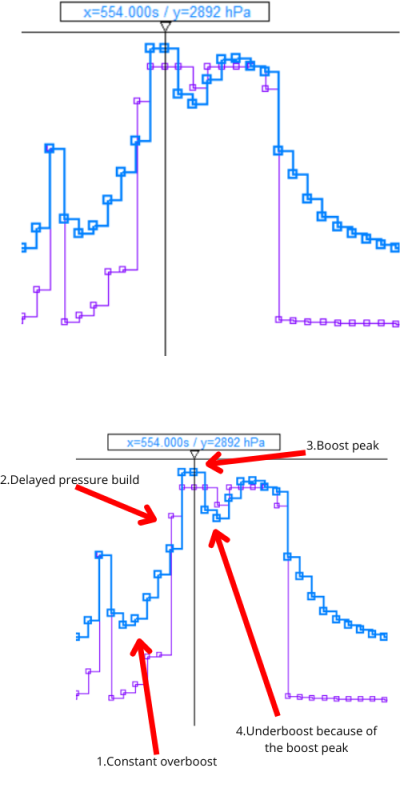

Another issue arises during

full-load acceleration: the

boost pressure build-up is slightly delayed. Then, as the

VNT vanes close, the pressure builds too quickly, resulting in a

boost spike.

Due to this

overboost, the

VNT rapidly opens to bring the pressure back to target, but the correction happens too aggressively, leading to an

underboost. Since the

smoke maps are carefully calibrated, the drop in

boost pressure causes a slight

reduction in injection quantity, making the car feel hesitant.

Here a very nice view of all the problems :

These issues are directly related to

PID regulation. After extensive testing and attempts to calibrate the PID, it became clear that achieving proper control was nearly impossible.

The

core issue was preventing

boost peaks while

smoothing the response and, at the same time, improving the

turbo’s reactivity when the

boost target increases rapidly. I think you try to understand the complexity...

What I Tried:

Copying the PID values from the LS version:

I knew it wouldn’t work perfectly (Because

each PID parameter is dependent on the specific system), but the results were catastrophic. The

boost pressure became completely unstable, even with slight acceleration, and the car

jerked severely.

Softening the LS PID settings:

Despite multiple adjustments, the

jerking persisted. So, I reverted to the

stock PID settings and focused on fixing:

- Constant overboost when cruising

- Boost delay

- Overboost spikes

Testing multiple PID and VNT preposition settings on the stock 2056 PID:

I created and tested

at least 15 different files with adjustments, but nothing led to satisfactory results.

Realizing that

modifying the existing PID settings wasn't effective, I decided to take a different route:

Zeroing out all PID maps. I first attempted to

calibrate the VNT preposition map from scratch. However, even after doing this,

boost pressure remained unpredictable. At

medium and high injection quantities and low RPM (<1800 RPM), the

VNT followed the position target correctly.

But past

1800 RPM for low injection quantities, the

VNT suddenly closed for no apparent reason, deviating significantly from the preposition target and producing a major overboost.

I discovered that a

PID function exists to lower backpressure, so I disabled the

exhaust backpressure regulation PID. However, despite this change, the issue

persisted, and I continued to experience

high boost pressure at partial load, particularly at 130 km/h.

At this point, after weeks of testing, searching in the file, and data-logging the car, it was impossible to just obtain the correct VNT position from the basic preposition map, and I wasn't able to find the problem.

Conducting these kinds of tests is incredibly

frustrating. Every time a new setting results in

poor drivability, it feels like I’m moving further away from the car’s

comfort and intended purpose rather than improving it.

So, because of all these issues, I’ve

given up on the

2260VKLR turbo. If you want your car to perform significantly

harder than the original setup without compromising on

smoke, drivability, or comfort, this turbo is

too difficult to manage.

Maybe it would work for those who

don’t mind a bit of smoke by making the

smoke maps less restrictive to prevent the injection limitation when

boost pressure drops, as I explained earlier.

However, I don’t want to make compromises. My feeling is that,

even though I would have loved to use a ball-bearing turbo, it will be

much easier to build a solid setup with a simple plain-bearing turbo.

If you add to this

difficult calibration the fact that the

22 turbine and hot side are very restrictive, it becomes clear that the

2260VKLR is not well-suited for achieving high performance on the OM642.

I don’t have a

tuned LS version to measure the

backpressure from a 350d Stage 1, but I suspect it would be

higher than 4200 mbar.

Conclusion of the 2260VKLR Adventure

This turbo works without issue if installed in the car

without increasing the stock

1.3-1.4 bar boost pressure of the original

2056 turbo.

Fuel consumption decreases significantly, despite the

constant overboost at partial load.

I recorded

5.6L/100 km on the dash and

5.8L/100 km measured at refueling during a

600 km highway trip at 110 km/h, and I achieved this result multiple times. However, this

changed after I attempted a MAF delete tune. Don't do a MAF delete on this engine. It will lead to

very bad fuel consumption.

If you look at the

range display, you can see the car showing

34L for 621 km, which is approximately

5.5L/100 km.

In the picture, I had already driven

140 km under different conditions, so don't take the

750 km for 46L into account (the car has an

80L tank).

Unfortunately, I can't find the

original pictures from the first time I achieved this low consumption, nor the

gas station receipt...

You will have to take my words on it this time.

Keep in mind that my

W211 is equipped with

245mm front tires and 265mm rear tires. With

220mm tires, fuel consumption might have been around a real

5.4L/100 km or lower, which I think is great for an E class and V6 diesel engine that produces around 290hp on my car with the 2260VKLR.

The installation of the

2260VKLR was difficult, and to be honest,

not worth the effort. The

PID issue with a

ball-bearing turbocharger cannot be easily solved. This means that, despite the

ballbearing technology of this turbo,

adapting it to software that isn't designed for it is

practically impossible.

But what’s interesting is that this

turbo runs perfectly on the stock power software, you won’t notice any difference in drivability, and

fuel consumption is significantly lower. On top of that, the

ball-bearing technology is highly reliable, and since the turbo is

water-cooled, it helps

reduce oil coking, making the setup even more appealing.

For now, I’m

keeping it in my car while I work on building a setup that can handle

750Nm with a

manual gearbox and dual-mass flywheel. I won’t clutter

Stevie’s thread with my project updates, but if some are interested, I might

start my own thread later.

At the end, which turbocharger is best ?

It's clear that the

GT22 turbine and the hot side of the 2260VKLR choke the engine and are

too restrictive. A

23 AMG turbine or any

23 turbine with a larger VNT shroud is

necessary to achieve

low backpressure. However, to run at

2.1 bar boost, like

Steve’s car, I believe a

65mm compressor might not be necessary. A

62mm compressor could be sufficient. I need to

confirm which compressor is the most suitable by consulting

compressor wheel manufacturers.

The

spooling performance of a turbocharger is

strongly linked to the compressor wheel size.

The larger the compressor, the slower it spins. Reducing the

compressor size would improve spool time.

Is it worth running more than

2.1 bar boost pressure? I don’t think so. Ultimately, it’s always a question of

reliability.

When tuning

Stevie’s car, I initially thought I had reached the

limit and that the engine might not handle the power. But in reality, the

OM642 seems more capable than many people assume—as long as it’s tuned

carefully, especially in terms of injection

timing. Stevie’s car is still running strong, and believe me, unless you’re

driving in Germany, you

won’t push the car from 100-200 km/h as intensely as he does.

The results from

Saunders have been

very impressive as well. He tuned his car

much more aggressively than we did, and it ran in this tuned state for

several years—until an

exhaust manifold failure destroyed the hybrid turbocharger. Unfortunately, the

exhaust manifold issue spares no one.

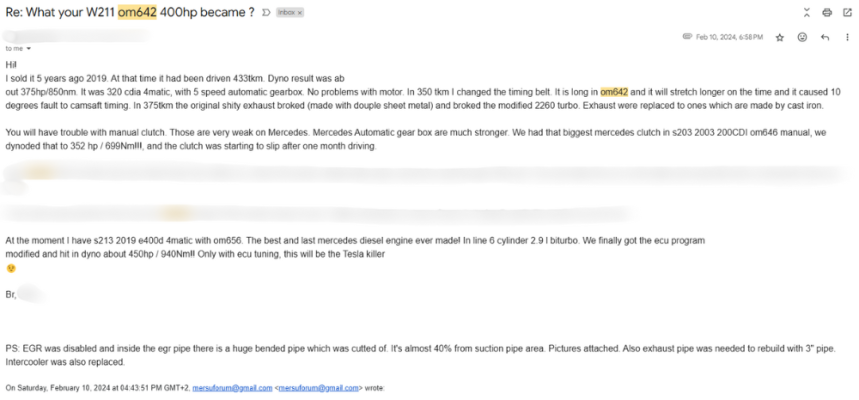

Also, I asked

"mirmir69" from

www.mersuforum.net, and by chance, I got an answer, one year before ! I'll share it with you here.

So, in my opinion,

2.1 bar is the best compromise. Many people are frustrated that the

OM642 struggles to exceed 350 hp, but

power figures don’t tell the whole story—it’s about

overall performance.

I even made a

comparison video with two

OM648-powered cars tuned to 400 hp, and Stevie’s car

isn’t far behind at all. Of course, we need to consider that

his CLK is lighter than an E-Class, but still, the

performance is there.

For those curious, here’s the video:

And I want to highlight that the

CLK is equipped with an

intercooler, a hybrid turbo, and an exhaust from a CLK500—nothing fancy.

Future Testing: GT2362V

We need to confirm, but I think a

GT2362V is the best compromise between:

- Spool time

- Maximum boost pressure

- Exhaust backpressure

In the future, I plan to

test this setup after getting confirmation from a

compressor manufacturer regarding the

compression ratio and airflow characteristics of a

62mm compressor.

I believe I can now say that I have

extensive experience with this

engine and ECU. Since I’ve received messages from enthusiasts looking for

high-quality tuning after facing issues with so-called

"professional tuners", here is my

Facebook page if you have a project and would like to contact me :

Log in to Facebook

If I get

enough projects, I will try to be

more consistent in sharing

detailed data on my tunings. Additionally, I’ve worked on

OM648 tuning, aiming to create a

fully calibrated software, just as I did for the

OM642. Surprisingly, despite the

OM648 being more commonly tuned, the

quality of tuning files for this engine

seems even worse than on the

OM642 side...

I hope the information I’ve shared will help some of you

make an informed decision about your

OM642. If you enjoy this kind of project,

let me know, and I’ll be happy to

share more in the future!