chesterpiglet

Active Member

- Joined

- Oct 8, 2008

- Messages

- 319

- Car

- Mercedes W211 E280 Cdi Sport Estate

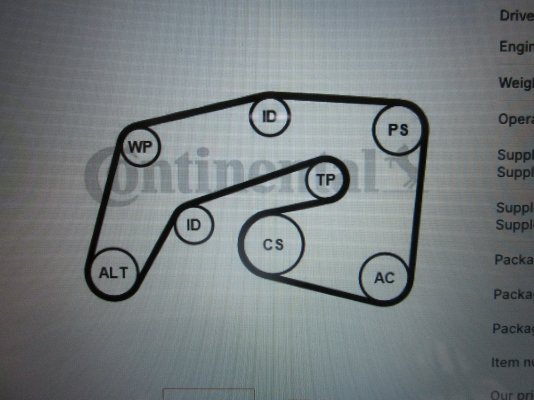

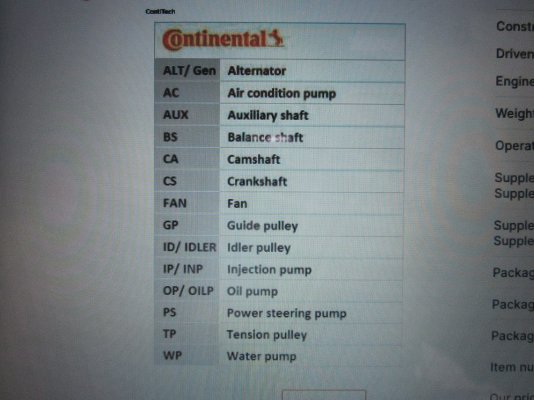

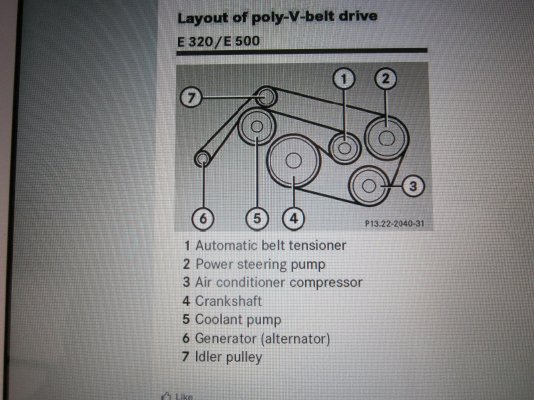

Poly V Serpentine belt snapped on Monday. I have the correct MB belt A002993429664(thanks for the help btw) & have been advised to check all the pulleys to find the cause of the failure. The 1st photo shows the old belt- it looks pretty ancient to me. I cannot find the exact belt diagram for mine(2008 W211 E280 3.0 Diesel Sport) so if anybody has it could they post it please? I found similar(photo 3) with 7 pulleys & mine has 8. Obviously the crank pulley moves & 6 all turn freely for the A/C, alternator, water pump etc but one does not turn which is the tensioner pulley(photo 2). Am I right in thinking when there is no belt on it it rests on the bracket next to it(2nd photo) preventing it from doing so(with the belt on it is held under tension in a different position?)-is this correct? The obvious thing to do is put a socket on the tensioner bolt & turn it to the left but I cannot see where this is- can you help? Photo 5 shows a pulley which spins freely but looks to be covered in "something rough"(it does look as though it could be removed though as you can see the lip of the pulley), clearly it shouldn't be like this so what's it called & how do I remove it? Photo 4 shows a part which I believe is the air intake pipe A6421400687 which needs to be removed to fit the belt, how does this come off? I'm getting grief from my French missus as to why I don't buy a modern car so I'm keen to try & do it myself. Any suggestions would be a god send. Many thanks as always. Rob.

Attachments

-

52E05570-51A4-4C2A-BCF9-01769957A2DF.jpeg1.7 MB · Views: 23

52E05570-51A4-4C2A-BCF9-01769957A2DF.jpeg1.7 MB · Views: 23 -

D1A990F4-B482-4793-9412-DEBAF0C1558A_1_201_a.jpeg1.7 MB · Views: 19

D1A990F4-B482-4793-9412-DEBAF0C1558A_1_201_a.jpeg1.7 MB · Views: 19 -

98F50823-1D79-4A62-8FC4-91F2190720FE.jpeg1 MB · Views: 20

98F50823-1D79-4A62-8FC4-91F2190720FE.jpeg1 MB · Views: 20 -

0674D3A2-34D9-479A-B663-140E82D1705B_1_201_a.jpeg540.6 KB · Views: 25

0674D3A2-34D9-479A-B663-140E82D1705B_1_201_a.jpeg540.6 KB · Views: 25 -

7D7C844A-0439-4400-AFBB-2451F36AE683.jpeg658.5 KB · Views: 23

7D7C844A-0439-4400-AFBB-2451F36AE683.jpeg658.5 KB · Views: 23