MrGreedy

MB Enthusiast

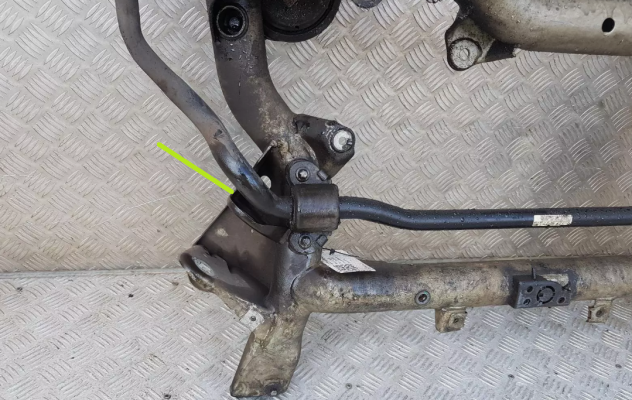

I think removing the 3 torx bolts to disconnect the hub from the bottom of the suspension strut will help for an on-the-drive DIY job, as it means you can get a bit better access to the arms and ball joints plus able to move stuff around better. It also means you can use a proper ball joint splitter on the front control arm to hub ball joint, rather than bashing a pickle fork in.

Agreed when watching the vid I didn't think brake disc or dust shield removal was necessary.

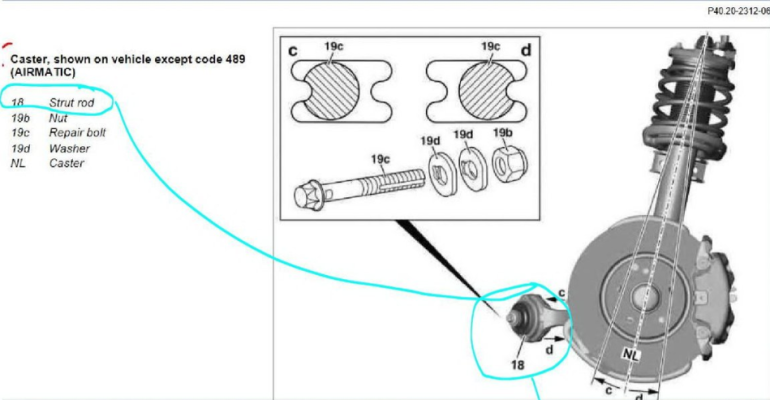

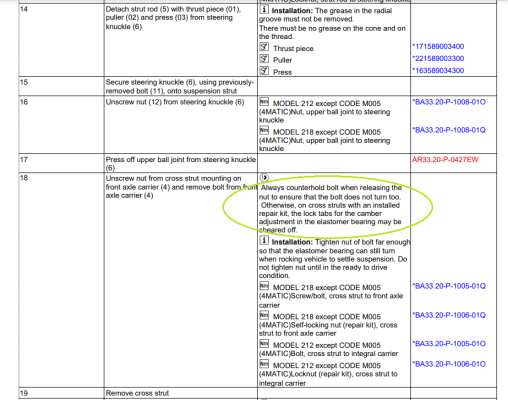

@BlackC55 how do you torque the control arm bolts on reinstall as it looks like you can't get a torque wrench directly on to the nut (we might need to avoid turning the bolt which is easier to access if it's got the camber adjustment bolts installed)?

Is it by using a crows foot adapter or box spanner torque adapter on a torque wrench, or removing the ARB?

Agreed when watching the vid I didn't think brake disc or dust shield removal was necessary.

@BlackC55 how do you torque the control arm bolts on reinstall as it looks like you can't get a torque wrench directly on to the nut (we might need to avoid turning the bolt which is easier to access if it's got the camber adjustment bolts installed)?

Is it by using a crows foot adapter or box spanner torque adapter on a torque wrench, or removing the ARB?