I'm sure I must have documented this somewhere on this forum, but I ended up renting a lift at a place just outside the M25 and replaced all the control arms on the front, the ball joints, the ARB drop link on the rear, and the front track rod ends. I have a new phone so don't have pics on my phone of the occasion (it was a while ago).

I'd already done the front ARB drop links (as per this thread) so I re-used them as they were pretty new.

I was lucky that the person that runs the lift service was a mechanic and was at hand to help out with e.g. a heat gun for the track rod ends which weren't coming off, and he also had an impact gun that I could use. I probably couldn't have done it without his help, at least not in a day.

@MrGreedy is more accomplished with his mechanic skills than me, though! Plus if you're doing it on your drive and have a second car, there's less time pressure.

It was pretty hellish as it was my 'first time' and I was under pressure to get it done in a day. I did 'enjoy' the experience (in hindsight) and learned so much - certainly I have a different level of skill compared to 4-5 years ago when I started this thread - but on my other W212 I have to be honest that next time I'd take it to

@BlackC55

It was just after this I took it to PCS for a gearbox service, actually.

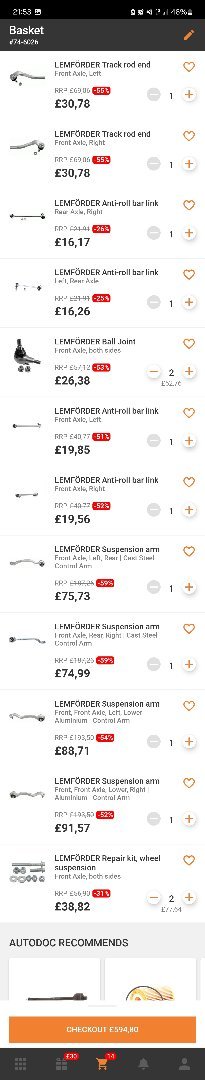

Once you add up the cost of parts + a decent indie fitting, it is not cheap or easy work, it can easily push into the thousands, and you haven't even changed springs and struts or top mounts... or much of the rear suspension at all!

I certainly wouldn't do it without a lift!