A huge topic so my intention here is to explain an overview not the entire package.... I think you will understand what i mean as you read this explanation.

For the domestic vehicle the standard "suggested" pressure is determined by the vehicles weight, the tyres aspect ratio and contact patch.

A predetermined internal pressure is suggested to compliment the tyres deliberate structure to enhance the handling properties desired by the manufacturer, tyre and car respectably.

So why the variants?

Air is not an efficient form of inflation!.... Within the composition of air some of the various molecules are susceptible to heat, in particular "water".

Since the holy grail of tyre technology is the transition of heat into the silica to accelerate traction properties the failure of air to maintain a constant value seems ridiculous..... But that's the way it is and the reason for this explanation.

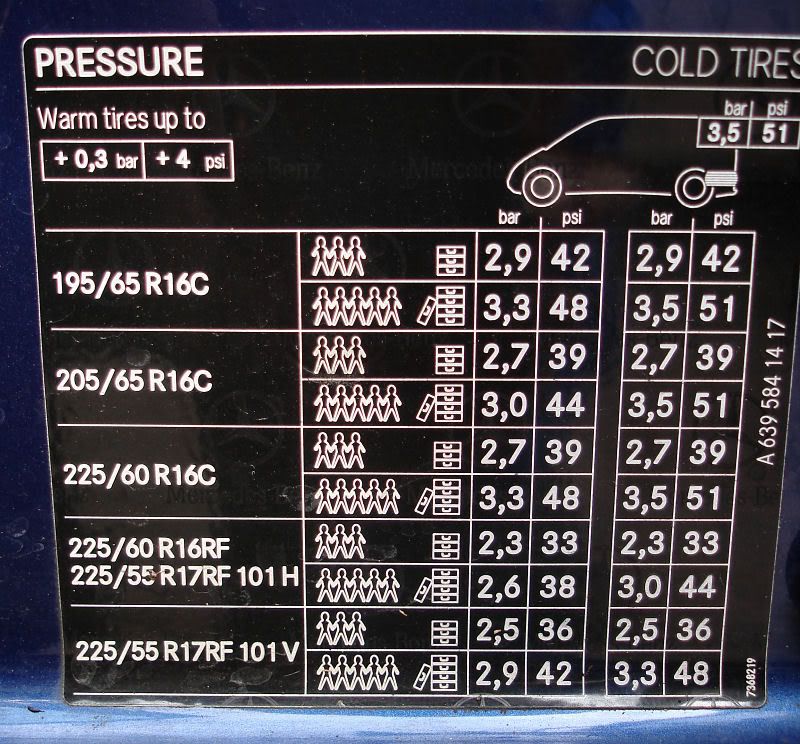

Ok so what do we have then?..... Most manufacturing guides will offer three ranges

1> Normal pressure

2> Loaded pressure

3> High speed pressure

Why

As i have explained air is inefficient and the silica needs heat for traction, it's unreasonable to expect the owner to stop and change the pressure during any journey, although it is possible to predict how the air will expand and suggest a initial cold pressure to cover the fields above.

How

Manipulate the tyres contact patch.... All three fields have known parameters so it's possible to manipulate how hot or cold the tyre will be-become within those fields..

Pressure stages

If for example our imaginary car is intended for town use then the suggested pressure may be 28psi, this comfortably assumes 30mph and a full tyre contact patch with minimal temperature/pressure gains

If the same car was intended for motorway use an initial cold pressure of 34psi may be suggested to reduce the size of the tyres contact patch thus reducing the thermal internal expansion to a pre-calculated average level.

The loaded pressure is a harder topic

Since the guidelines for loaded "motorway" pressures is very vague the normal intention is to aid the tyres construction and maintain a full contact patch after the internal expansion.... It's also assumed the speed limit will be around the 70mph mark so centrifugal forces are expected to distort the higher pressure suggestion but the exact level is theoretical.

Non-standard tyres

Changes in the tyre width or aspect ratio will belay all guidelines offered by the manufacturer. It's reasonable to assume the replacements are not to distant from the OEM fitment so it's wise to adopt the original pressures as a template then read the handling/wear traits and adjust accordingly.

Reading the signs

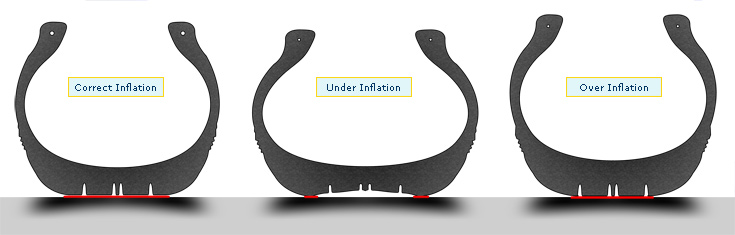

Tyre wear due to inflation levels is easy to observe and correct (see image at top of page) but handling traits due to tyre modification needs a little more understanding.

A common modification is to go low and wide, so how do you judge the pressure now?

If the pressure is to high at the front the low aspect ratio tyre will have a tendency to "tram-line". This is due to the inflexibility of the tyres sidewall. If the rigidity is to high then the transient grip can no longer be absorbed within the sidewall and perpetually steer the car.

Additionally if the pressure is to low then the pneumatic slip angle will allow the wheel to transit between Yaw and the actual tyre contact patch. The effect is a numb, lazy feel to the steering.

Finally there is a need to balance the tyres footprint and sidewall rigidity front and rear despite the obvious weight disparities.. If for example the rear footprint is low due to high pressure then the car will over-steer...To much footprint then the opposite can be said

All examples can be manipulated by small changes in the cold tyre pressure, examples of "over-under-steer" by manipulation.

In summery

As you may have noticed i keep saying "suggested" pressures? The reason for this is that no manufacture can cover all examples, so it's up to you to decide the correct pressures for your own unique example