G7Wagen

Active Member

You will see this linkage is straight, and has an open ball-joint head. make note of it for future reassembly identification

Step 10

Next we move over to the drivers side (RHD)

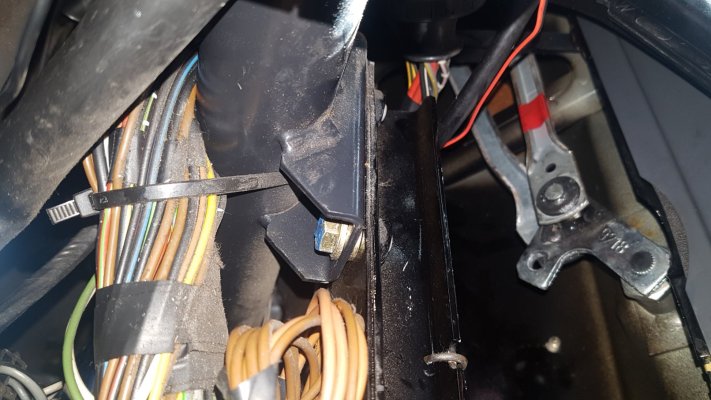

and if you look carefully through the opening on top of the dash you will see the drivers side wiper spindle linkage.

This linkage has two ball joints and connecting rods.

The wiper motor links to this to operate the drivers side wiper (Crooked linkage) and continues on through the second linkage to the passenger wiper (straight linkage)

For my reference i marked the front passenger side linkage with some red tape to assist in re-assembly and so i knew which end went where.

Using the same method as before carefully pop off both the front and rear wiper linkage rods. You can leave them in place if you wish as there is no need to remove them.

If you buy a complete linkage from Mercedes, you will still need to dis-assemble it to be able to slide the linkage rods through the small space behind the heater.

Step 11

Now we finally come to the removal of the wiper spindles themselves.

for this you will need an assistant, x2 -22mm open ended spanners (or x1 -22mm open ended spanner and a large adjustable spanner).

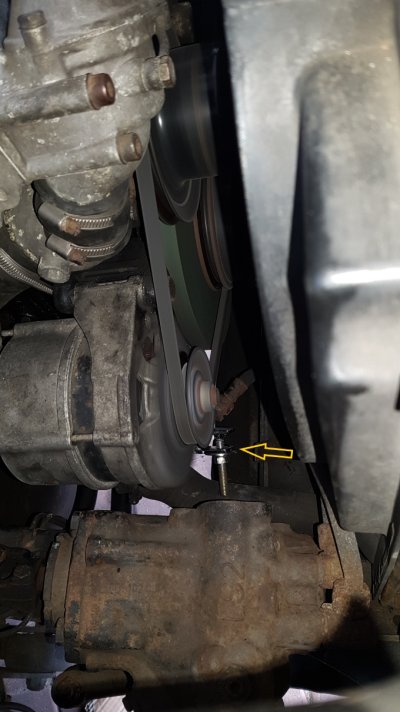

Lets begin with the passenger side (RHD) use the open ended 22mm spanner to hold the nut on the rear of the passenger side wiper spindle.

Your assistant should now start to undo the nut on the outside of the spindle, having first protected the area with cloths or some masking tape to avoid paint damage...

once undone, carefully remove the nut, metal washer and whats left of the old sealing washer.. the spindle should then come out from the hole under the dashboard.

Step 12

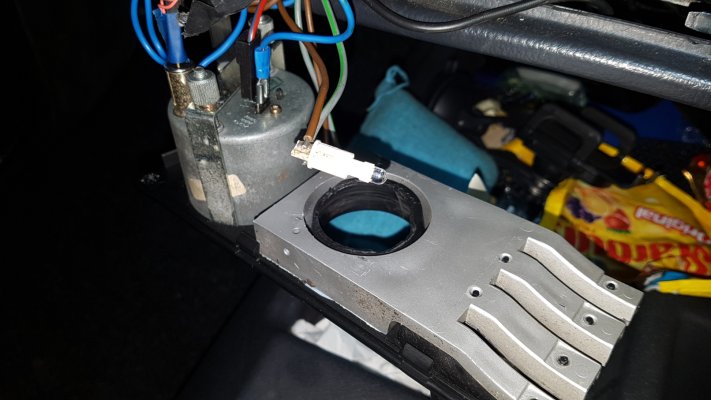

Lets now move onto the drivers side spindle... which you will see through the hole where the instruments once sat.

same procedure... 22mm spanner on the nut on the inside, and if like me you have long arms... you may be able to reach the nut on the outside and undo this one on your own, and remove it into the inside of the car..

Step 13

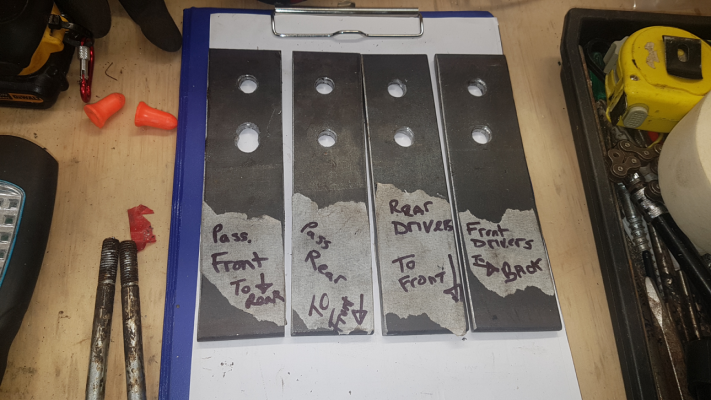

Now with both spindles removed lay them next to your new ones and look for any differences.

The passenger side may have a slightly cranked arm.. and the new one straight- this will make no difference once fitted.

The drivers side wiper spindle must have all the ball joints on the new one in the same positions as the old one... If they are, no problem.

If you find (like me) the drivers side spindle has all the ball joints in the wrong place, they will need to be moved. For this you will need access to a mig welder or someone who can do it for you. (All the info on this is in its own section at the end of this thread).

Here are some examples;

last pic. New Wiper spindle for drivers side with ball joint positions corrected (by Me)

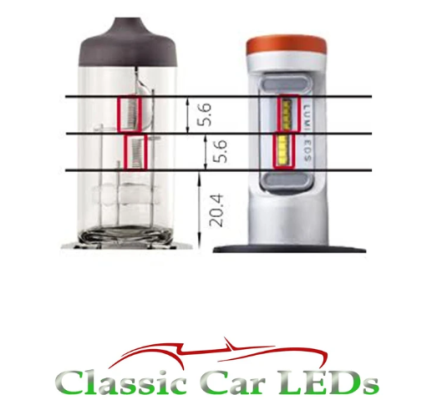

Check also that you have the correct washers, two shiny metal and two special cloth/rubber material washers.

If you have a large black rubber washer and a black metal washer this is wrong. Do not fit these as the rubber washer is incorrect and will squeeze out under tightening of the wiper spindle and will not provide a water resistant seal. (I have no idea how I ended up with these, but had to obtain the correct washers from a friend) you should also have new black fixing nuts.. but if not you could re-use your old ones.

Here is a picture of the correct washers (bottom row), metal washer then special sealing washer.

Top 2 washers in this pic are the wrong rubber type washers .

Step 14

Reassembly.

Assuming you have all the correct parts.. give the spindle holes some attention... clean them up, and if like mine they are chipped, touch in any paint chips and leave to dry (overnight is best) before-

After

Once your Spindle holes are ready smear grease over the spindle and in and around the hole and insert the passenger side spindle from inside and smear some grease where the special cloth/rubber washer will sit, and slide it onto the spindle, next smear some more grease on the fitted washer and slide the metal washer on top. Now fit the black 22mm nut to secure the spindle, and with the 22mm spanner get your assistant to hold the inner spindle nut, while you tighten the nut on the outside of the spindle till its nice and tight. clean off the access grease and coat the inside of the plastic cup that covers the cap and slide it on.

The procedure for the Drivers side spindle is slightly different.

First you will need to make sure the the connecting rods are in the correct position.. if like me you removed them, you will need to temporarily tape them together so you can slide them in behind the heater in one go first threading them through the glovebox opening.. Once in there make sure the straight link rod is nearest you with the open side of its half round profile towards you.

The other linkage is cranked and this faces the same way as the front but attaches to the rear of your drivers side spindle, and has a closed ball-joint, which if it was fitted after poking the spindle through the hole in the bulkhead it would be very difficult to fit. If you can see the open profile of the linkage it is the correct way round.

Grease the two ball joints on the link rods at the drivers end and both the ball joints on the drivers spindle. now carefully using a large pair of grips squeeze the ball-joint back onto the rear ball that faces the bulkhead.

Top