Poynty

Member

- Joined

- Jan 26, 2022

- Messages

- 46

- Location

- Guildford

- Car

- Mercedes C300 Premium Sport Coupe (Late 2016 W205)

Hi guys,

I’m fairly novice to mechanics, wanting to be able to take my wheels off to clean / if have tyre issues in future.

I’ve currently got the Torque wrench (FOURROBBER Torque Wrench1/2-Inch Drive Click 25-220 Nm Dual-Direction Adjustable Torque Wrench Set Amazon.co.uk)

But thinking of changing to the digital adaptor as it feels like it’ll be less prone to human error and more accuracy? (ThreeH 1/2''(1.5 to 147.6 ft-lbs.) Heavy Duty Digital Torque Adapter with LED&Buzzer Alert (1/2'' Drive & Includes adapters for 3/8'' and 1/4'') Amazon.co.uk)

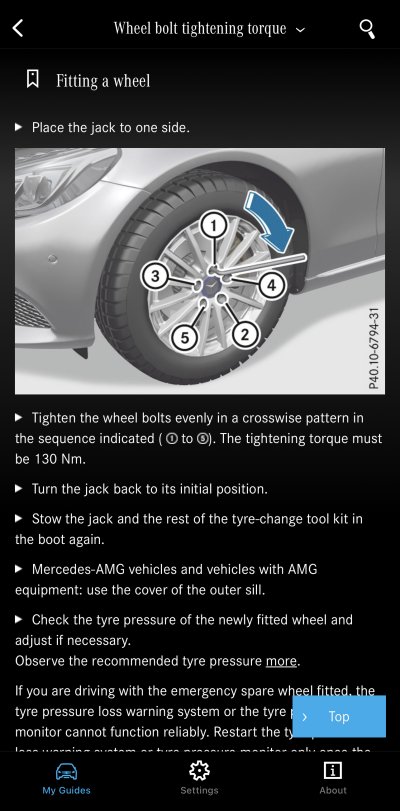

What do you all think, any tips and instructions on this, for specs I think my Mercedes C300 Coupe 2016 April Reg is 130nm torque for bolts from reading online.

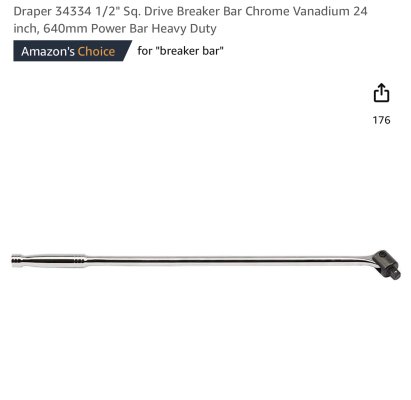

Also if agreement with changing to digital adaptor, would a standard non torque rachet work best or a breaker bar.

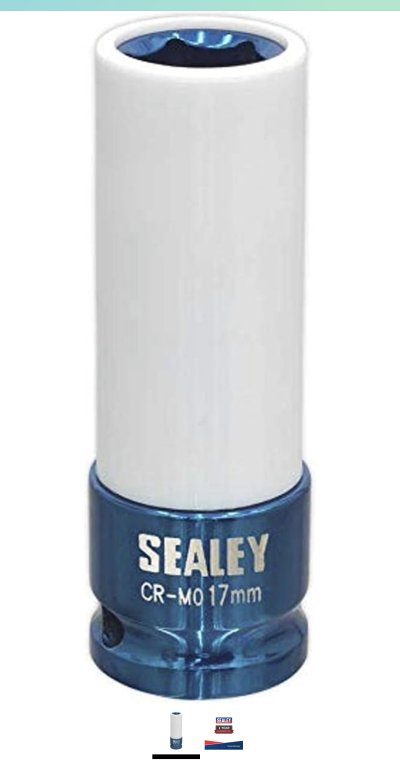

I’ve got a vonhaus corded impact wrench, breaker bar & 17mm 1/2 wrench socket (fits my wheel bolts)

Also got Halfords 3 ton hydraulic trolley

Photos attached for context of what I have and torque wrench and digital adaptor I am considering changing from and to.

I’m fairly novice to mechanics, wanting to be able to take my wheels off to clean / if have tyre issues in future.

I’ve currently got the Torque wrench (FOURROBBER Torque Wrench1/2-Inch Drive Click 25-220 Nm Dual-Direction Adjustable Torque Wrench Set Amazon.co.uk)

But thinking of changing to the digital adaptor as it feels like it’ll be less prone to human error and more accuracy? (ThreeH 1/2''(1.5 to 147.6 ft-lbs.) Heavy Duty Digital Torque Adapter with LED&Buzzer Alert (1/2'' Drive & Includes adapters for 3/8'' and 1/4'') Amazon.co.uk)

What do you all think, any tips and instructions on this, for specs I think my Mercedes C300 Coupe 2016 April Reg is 130nm torque for bolts from reading online.

Also if agreement with changing to digital adaptor, would a standard non torque rachet work best or a breaker bar.

I’ve got a vonhaus corded impact wrench, breaker bar & 17mm 1/2 wrench socket (fits my wheel bolts)

Also got Halfords 3 ton hydraulic trolley

Photos attached for context of what I have and torque wrench and digital adaptor I am considering changing from and to.

Attachments

-

IMG_4557.jpeg1.9 MB · Views: 5

IMG_4557.jpeg1.9 MB · Views: 5 -

IMG_4562.jpeg172.7 KB · Views: 3

IMG_4562.jpeg172.7 KB · Views: 3 -

IMG_4563.jpeg261.3 KB · Views: 2

IMG_4563.jpeg261.3 KB · Views: 2 -

IMG_4564.jpeg536.9 KB · Views: 3

IMG_4564.jpeg536.9 KB · Views: 3 -

IMG_4561.jpeg818.6 KB · Views: 5

IMG_4561.jpeg818.6 KB · Views: 5 -

IMG_4548.jpeg1.2 MB · Views: 6

IMG_4548.jpeg1.2 MB · Views: 6 -

IMG_4551.jpeg573.5 KB · Views: 7

IMG_4551.jpeg573.5 KB · Views: 7 -

IMG_4550.jpeg417.1 KB · Views: 5

IMG_4550.jpeg417.1 KB · Views: 5 -

IMG_4554.jpeg390.7 KB · Views: 2

IMG_4554.jpeg390.7 KB · Views: 2

Last edited: