unclebuck

Active Member

- Joined

- Oct 19, 2016

- Messages

- 338

- Car

- CLS 320 /08

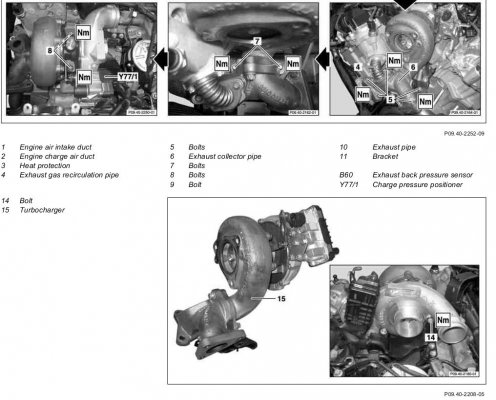

Ok i decided to fish out the two intercooler pipes this afternoon, they were very dirty and there was a little wear mark on the metal work behind the one on the passenger side. The pipe the drivers side had a little oil inside it so i am thinking that the turbo needs replacing soon. I am going to put the car up on stands next weekend and disconnect the intercooler and give it a flush out, clean things up and refit along with the new pipe seals, so i cleaned the pipes up and refitted them, no marks, splits in either pipe.

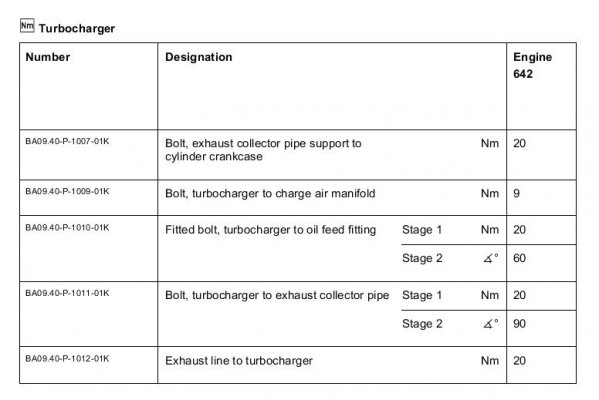

ordered the kit i need and i still have to order some of the other seals as well. I am still thinking of replacing the turbo cartridge myself and refitting, however it may just be quicker to get a replacent on an exchange basis to save time. This will allow me to have more time on removing the intake manifolds and sorting those and the oil cooler.

I have got all the parts now to make a diy boost leak smoke detector that i saw on youtube, a cheap bike pump on ebay for £4.99, a basic soldering iron that i already have, some tubing, and a couple of jubilee clamps and some baby oil with a rag, so if its nice tomorrow i will build that and see if it can fine any leaks anywhere.

ordered the kit i need and i still have to order some of the other seals as well. I am still thinking of replacing the turbo cartridge myself and refitting, however it may just be quicker to get a replacent on an exchange basis to save time. This will allow me to have more time on removing the intake manifolds and sorting those and the oil cooler.

I have got all the parts now to make a diy boost leak smoke detector that i saw on youtube, a cheap bike pump on ebay for £4.99, a basic soldering iron that i already have, some tubing, and a couple of jubilee clamps and some baby oil with a rag, so if its nice tomorrow i will build that and see if it can fine any leaks anywhere.