grober

MB Master

Here is a simplified version of how the throttle position linkage effects the throttle pressure acting against the governor pressure which is speed related. Under light acceleration a gear change would take place at a certain speed but under hard acceleration this change point is delayed till further up the rev range. All basically to do with the fact that in a hydraulically controlled box as speed increases hydraulic pressure increases and its how you modify /balance that increase in pressure to get the desired result in relation to road speed /engine speed /gear selected / accelerator position etc

Automatic Transmissions: Valves and Modulators - HowStuffWorks

this is a good nuts and bolts components " video of an autobox hardware.

[YOUTUBE]szu-0IqMygA[/YOUTUBE]

Automatic Transmissions: Valves and Modulators - HowStuffWorks

this is a good nuts and bolts components " video of an autobox hardware.

[YOUTUBE]szu-0IqMygA[/YOUTUBE]

Last edited:

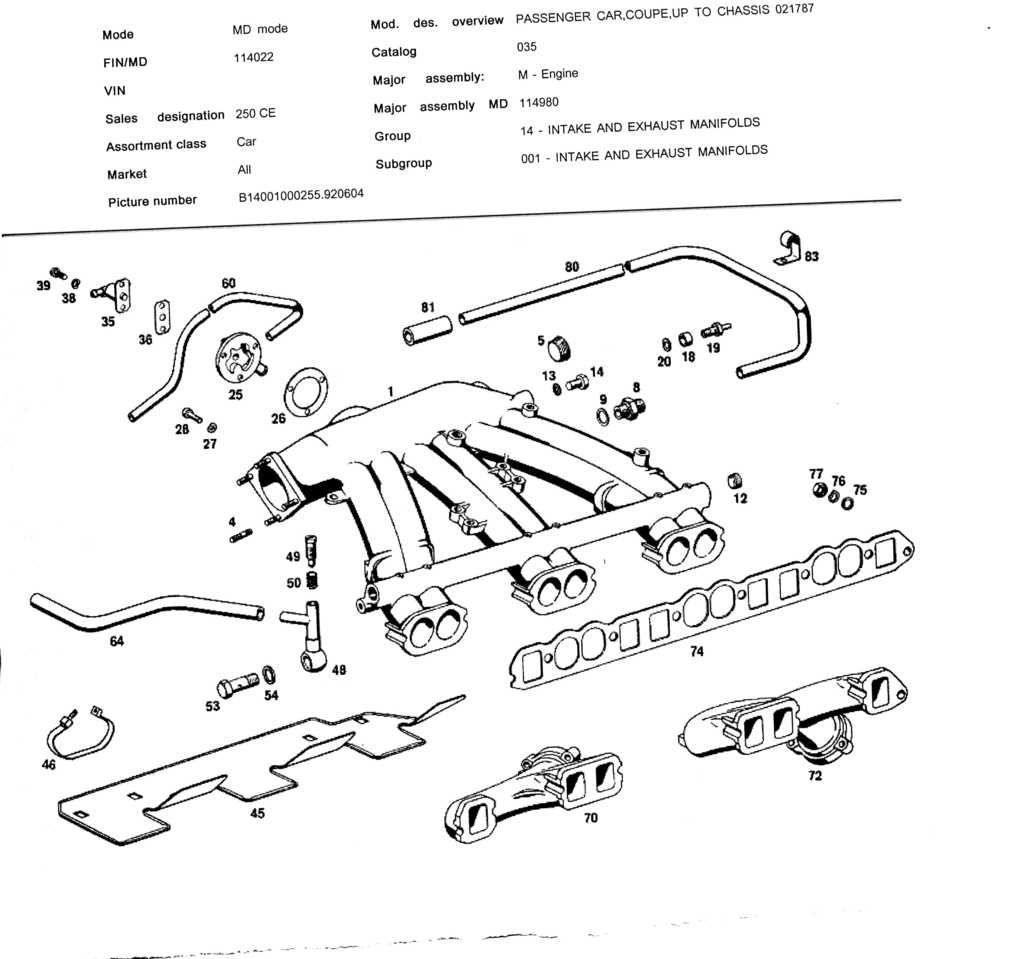

Mercedes of that era seem to like mounting their throttle linkages on the inlet manifold or cam cover. I imagine its almost impossible to see down there without the engine out of the car?

Mercedes of that era seem to like mounting their throttle linkages on the inlet manifold or cam cover. I imagine its almost impossible to see down there without the engine out of the car?