MangoMan

MB Enthusiast

- Joined

- Aug 10, 2005

- Messages

- 1,940

- Location

- Hampshire South Coast.

- Car

- 2001 W208 CLK320 Coupe Almandine-Black. (Looks Purple-ish).

Great project, I hope it all turns out ok, good luck!

Just noticed, the 'Redline' starts 750rpm. earlier on the new dials. Personally I think it will show an incorrect reading as the marks are in a different place. The dial calibration on the others seem ok.

You did notice this, didn't you?

Cheers, Bill.

Just noticed, the 'Redline' starts 750rpm. earlier on the new dials. Personally I think it will show an incorrect reading as the marks are in a different place. The dial calibration on the others seem ok.

You did notice this, didn't you?

Cheers, Bill.

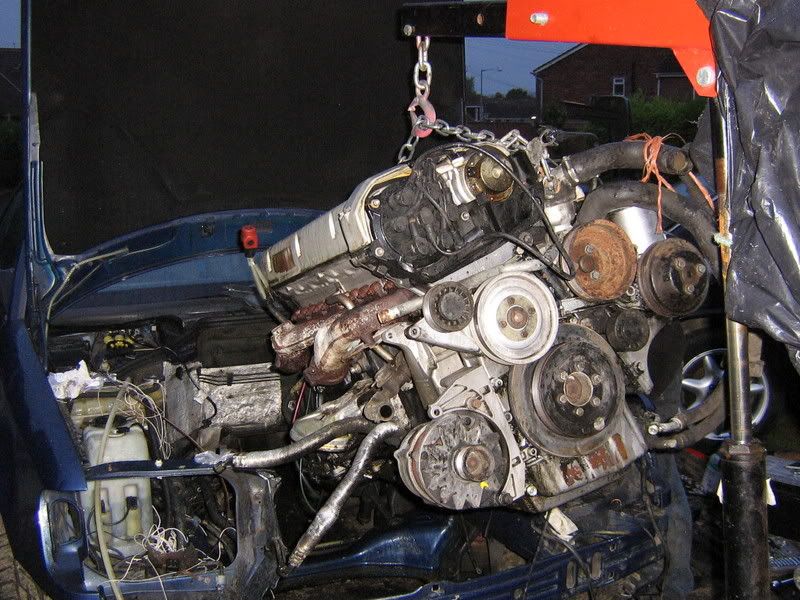

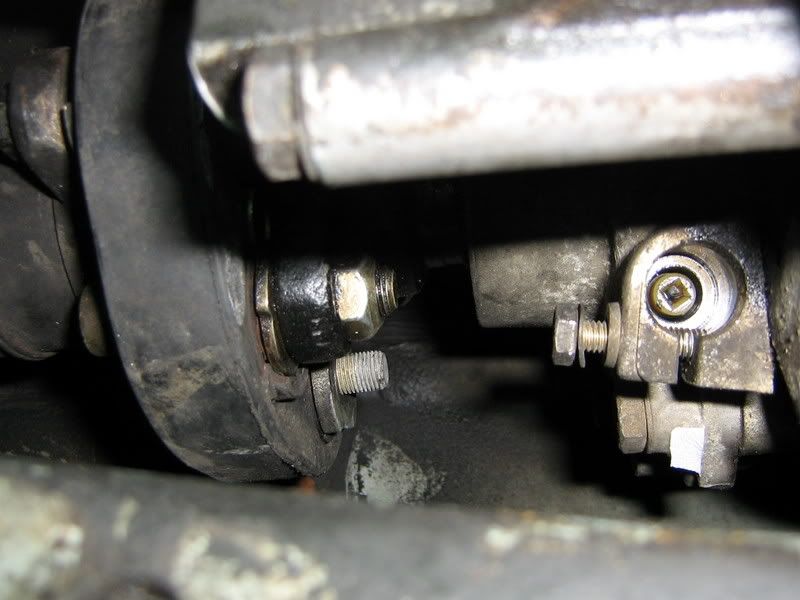

WTF was that, untill I take it off I have no idea why it broke Is the splined shaft, housing different or what?? so now do I either take the gamble with the box that came on the car with dodgy reverse and hope it was crap Fluid or try and source another for reasonable money?

WTF was that, untill I take it off I have no idea why it broke Is the splined shaft, housing different or what?? so now do I either take the gamble with the box that came on the car with dodgy reverse and hope it was crap Fluid or try and source another for reasonable money?