Smithy860

Active Member

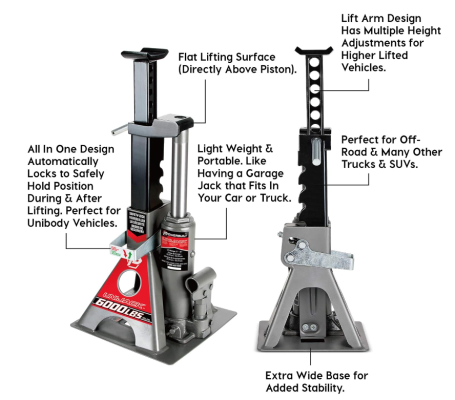

Appreciate the link , seems to be on the right lines i reckonThere are also axle stands that incorporate a jack and a mechanical lock, so they're not reliant on the hydraulics to keep the vehicle up. This sort of thing:

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Appreciate the link , seems to be on the right lines i reckonThere are also axle stands that incorporate a jack and a mechanical lock, so they're not reliant on the hydraulics to keep the vehicle up. This sort of thing:

Similar to some of the American offerings and a clever idea but just be aware of some less than encouraging reviews of this particular example .There are also axle stands that incorporate a jack and a mechanical lock, so they're not reliant on the hydraulics to keep the vehicle up. This sort of thing:

It comes with the inbuilt bottle jack limitation of restricted height. (My 'version' - had I built it - would have had the bottle jack inside the stand - concentric).Appreciate the link , seems to be on the right lines i reckon

Lift in stages?I’m thinking I’ll get a higher lift 3 ton jack from Halfords. Use the jack pads to lift and see about lowering onto suspension mounting at the rear. Hopefully can still lower the arm to get the spring in.

Failing that I’ll jack up and swap to axle stands on the jack pads.

It comes with the inbuilt bottle jack limitation of restricted height. (My 'version' - had I built it - would have had the bottle jack inside the stand - concentric).

True, but the bottle jack element can't lift to the extending post's full height. What it will give is a higher start point (so to speak) but only bottle jack limited additional height. In other words, it can initially be placed under a vehicle at a greater height but the restricted additional lift wont allow for complete suspension extension - tyres still on the ground the result.The one I posted (which I have no experience with - it was just the first of that type I found from a quick Google) has extending arms:

True, but the bottle jack element can't lift to the extending post's full height. What it will give is a higher start point (so to speak) but only bottle jack limited additional height. In other words, it can initially be placed under a vehicle at a greater height but the restricted additional lift wont allow for complete suspension extension - tyres still on the ground the result.

Yes. A bottle jack must by design, lift less than its own height.You could be right, but that would apply to just about any bottle jack ..

Not that many and, see my Jackshit thread where no one was interested in anything BJ. TJ all then way - for the height.. and people do use them successfully

Not seeing how.Looking at that one two post ujp....it does not look like bottle height will be a restriction as it looks like you can lock the axle stand part in place whilst you lower and reposition the bottle part to take it higher.....looks like it should be able to extend to the axles stands full height with no problem.

Oh and did someone say they lifted under the spring cups ? Then axle stand on the padsJust had another look underneath and I can see the suspension mount where the arm meets the mounting.

I see what people mean now about using support there, whether it be axle stand or jack. Just behind the diff, seems a plastic cover may partially obstruct

Well I had to take the 4 ton axle stands back and swap for 3 ton pair. They are a lower height and I’ve managed successfully and I feel safely to support the car.

I have a hardwood block that spans the entire width of the channel next to the jacking pad and I was very careful to feel how it lifted. Felt very solid and the channel ( which is the same the pad is attached albeit that has a welded assy) seemed very capable of jacking to desired height, no damage at all.

Front wheel is chocked and once the back wheel is off, that can go under next to the jack.

I tried the suspension area but couldn’t get anything as solid

Looks ideal!My wife and I hated it when our son was working under his 190D2.5, albeit on 4 VERY solid stands. He didn't like it either, but needs must. This was the solution:

View attachment 162319

RayH

I have no intention of being under it for long

Yes the concrete on my drive isn’t fantastic so I’ll spread the loads as much as I can too. I can’t see a situation where I’d really be actually underneath.Always stay safe.

For interest, the cost of the hoist was minimal. Thick concrete project managed by a master mason, minimal.

Cost of prime beef, duck and beer for the team, astronomical!!!

R

Since I purchased my Vito, I have worked under it quite (rather too many) a number of times. When I remove the wheels I always place two removed wheels stacked under the centre line of where I'm working (or as near to as is viable).Yes the concrete on my drive isn’t fantastic so I’ll spread the loads as much as I can too. I can’t see a situation where I’d really be actually underneath.

Not for a period of time anyway and certainly not without lots of fail safes in place.

When the kids are older I’d like to play around more with car mechanics (mechanical fitting is my trade) , in that case I’d definitely get a better set up, foundations , hoist etc.

It’s often not taken into consideration the cost of feeding a team!

That’s a very good idea, I’ve also seen people build a ‘wood tower’ and placing it under the diff just in case.Since I purchased my Vito, I have worked under it quite (rather too many) a number of times. When I remove the wheels I always place two removed wheels stacked under the centre line of where I'm working (or as near to as is viable).

Touching wood I've not had a disaster yet*, but my thinking is that if something unpredicted did occur whilst I was under there, the wheels should give me some extra security for very little inconvenience & no cost.

*Hope I'm not tempting fate.!

Just to complete the thread.That’s a very good idea, I’ve also seen people build a ‘wood tower’ and placing it under the diff just in case.

Considering the result of some sort of failure, it’s well worth having these fail safes I’d say.

We use essential cookies to make this site work, and optional cookies to enhance your experience.