SpikyMikey

MB Enthusiast

- Joined

- Nov 4, 2020

- Messages

- 7,011

- Location

- The Sunny South Coast

- Car

- BMW F31 330i LCI M Sport Shadow Edition Black Series AMG Touring

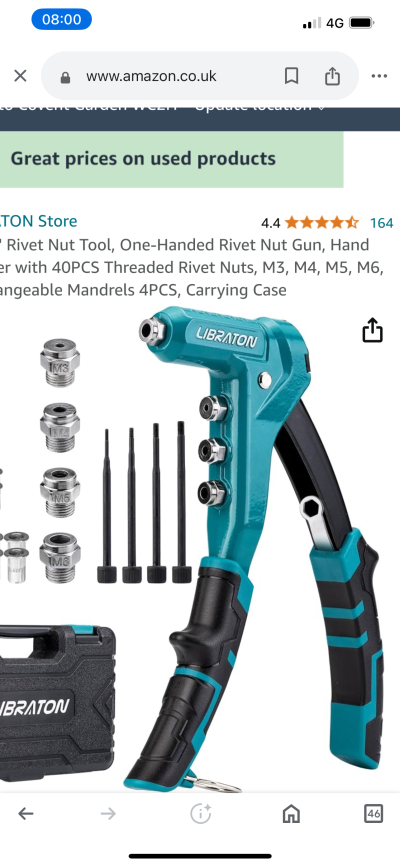

Another vote here for RivNuts in the frame (although I've never worked with Carbon Fibre. Maybe aluminium rather than steel rivet nuts as they require less pressure to set). And you'll need a rivet nut tool, but easy to get on Amazon or eBay.