mark.porthouse

Active Member

Hi All,

Just thought that I would share a recent experience with you:

The car with no warning would not start. Eventually nailed it down to a problem in the petrol supply as it would start on LPG (dual fuel) once I figured how to fool it into supplying gas for startup.

After a little looking around I noted that the fuel pump wasn't running. So I removed the fuel pump relay and stuck a (decent sized) wire across pins 30 (12V supply) and 87 (to fuel pump). The wire rapidly got hot and the insulation started melting.

So I figured that I had a dodgy fuel pump and that the relay will have blown too. Got replacements for them second hand. Still no running fuel pump.

I have now just realised that the wire supplying 12V to the fuel pump from the fuel pump relay has a short to earth, as with it disconnected at both ends I'm getting a circuit through to ground. However, the wire is still complete as I can get a circuit from one end of the wire to the other.

So I reckon that a dodgy fuel pump (and it doesn't sound as sweet as it's replacement) caused too much current in the supply wire, causing the insulation to melt (or potentially I merely had some chaffing in the wire which ended up contacting the wire with ground or perhaps I melted the wire myself as perhaps it wouldn't have melted if I hadn't shorted across where the relay would normally be.). So a short to ground from the wire somewhere.

The question now is: Do I replace the whole wire. It runs from under the bonnet by the battery to emerge underneath through a hole just forward of the fuel tank (remember this is an estate with the fuel tank at the back underneath). Does anyone know if this is a single wire? Also where does it run on it's journey from front to back?

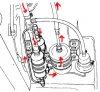

By the way, I reckon the fuel pump relay pinout is as follows (some inspiration from a poster on another forum (which wasn't entirely correct), some looking at the Haynes manual and some testing with a multimeter):

Fuel Pump Relay Pinout - W124 300TE 1988 (no catalyst, no air con)

15 -- +12V from ignition via OVP relay

30 -- +12V direct from battery (why no fuse?!!!)

87K -- transmission kickdown???

31 -- ground

87V -- to cold start valve

50 -- cold start signal

TD -- KE-Jetronic computer

TF -- KE-Jetronic computer

87 -- to fuel pump

Cheers,

Mark

Just thought that I would share a recent experience with you:

The car with no warning would not start. Eventually nailed it down to a problem in the petrol supply as it would start on LPG (dual fuel) once I figured how to fool it into supplying gas for startup.

After a little looking around I noted that the fuel pump wasn't running. So I removed the fuel pump relay and stuck a (decent sized) wire across pins 30 (12V supply) and 87 (to fuel pump). The wire rapidly got hot and the insulation started melting.

So I figured that I had a dodgy fuel pump and that the relay will have blown too. Got replacements for them second hand. Still no running fuel pump.

I have now just realised that the wire supplying 12V to the fuel pump from the fuel pump relay has a short to earth, as with it disconnected at both ends I'm getting a circuit through to ground. However, the wire is still complete as I can get a circuit from one end of the wire to the other.

So I reckon that a dodgy fuel pump (and it doesn't sound as sweet as it's replacement) caused too much current in the supply wire, causing the insulation to melt (or potentially I merely had some chaffing in the wire which ended up contacting the wire with ground or perhaps I melted the wire myself as perhaps it wouldn't have melted if I hadn't shorted across where the relay would normally be.). So a short to ground from the wire somewhere.

The question now is: Do I replace the whole wire. It runs from under the bonnet by the battery to emerge underneath through a hole just forward of the fuel tank (remember this is an estate with the fuel tank at the back underneath). Does anyone know if this is a single wire? Also where does it run on it's journey from front to back?

By the way, I reckon the fuel pump relay pinout is as follows (some inspiration from a poster on another forum (which wasn't entirely correct), some looking at the Haynes manual and some testing with a multimeter):

Fuel Pump Relay Pinout - W124 300TE 1988 (no catalyst, no air con)

15 -- +12V from ignition via OVP relay

30 -- +12V direct from battery (why no fuse?!!!)

87K -- transmission kickdown???

31 -- ground

87V -- to cold start valve

50 -- cold start signal

TD -- KE-Jetronic computer

TF -- KE-Jetronic computer

87 -- to fuel pump

Cheers,

Mark