HI All

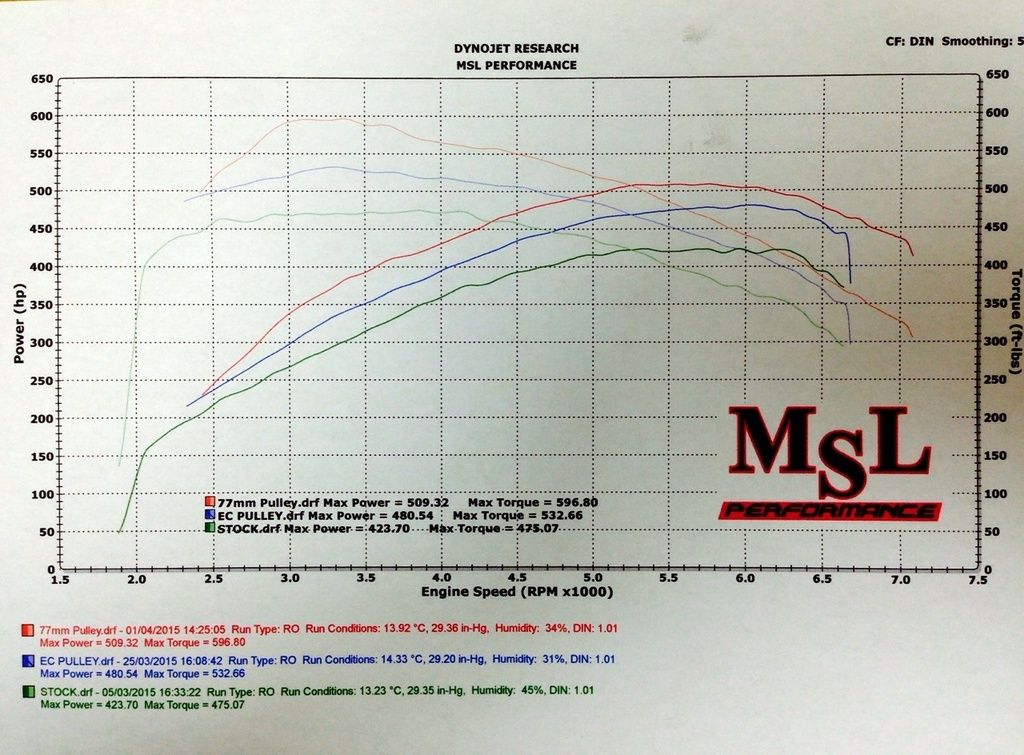

Well it looks like I just can't bring myself to part with my old wagon. I am therefore thinking about a s/c pulley change from my current 84mm one down to a 77mm. I know there are quite a few of you now out there running the smaller pulley, so I am after some genuine feedback and any negative experiences with one fitted. Also what mods have you needed.

Any info much appreciated

Well it looks like I just can't bring myself to part with my old wagon. I am therefore thinking about a s/c pulley change from my current 84mm one down to a 77mm. I know there are quite a few of you now out there running the smaller pulley, so I am after some genuine feedback and any negative experiences with one fitted. Also what mods have you needed.

Any info much appreciated