brucemillar

MB Enthusiast

- Joined

- Nov 18, 2010

- Messages

- 8,663

- Car

- C55 AMG Wagon - W124 300te 4matic Wagon - BMW 4.8is X5 E53 - SWB Pajero 3.5 V6 24v

I suspect that DRUK will not be offered any TATTOO work in the near future ;ˆ)

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

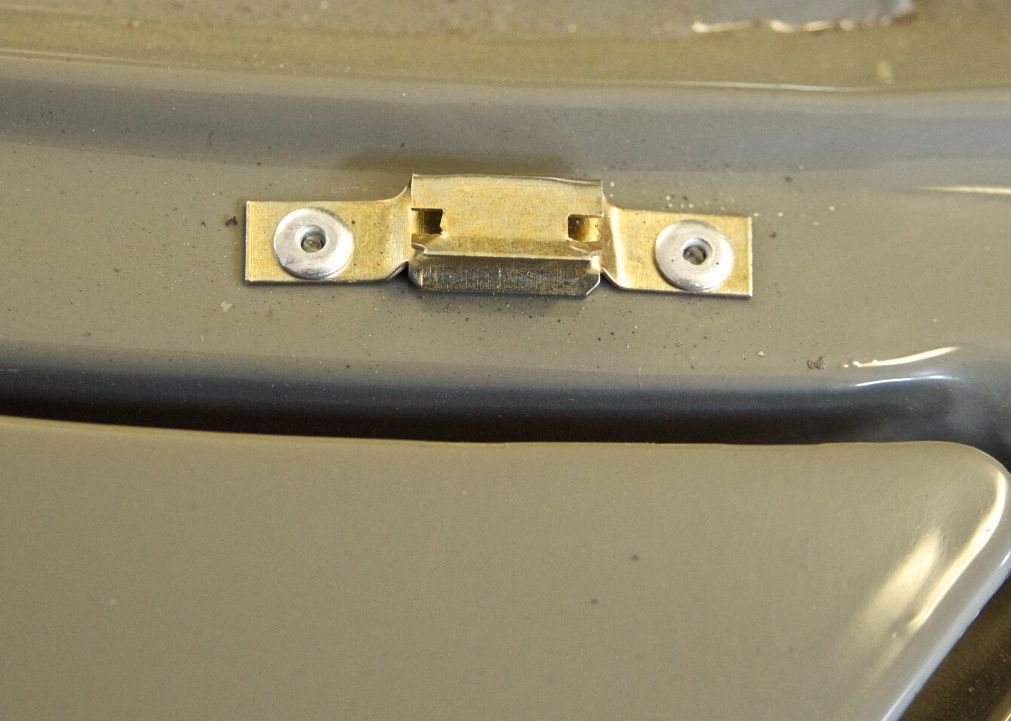

picture of the fuel rail attachment from the old 280 thread.

the new

the old

you can actually see the 3 black U shaped brakets that attach the fuel rail top and bottom better here .

THE THOUGHT NOW OCCURS- If the injectors are now retained firmly both in the cylinder head/manifold [ front end] and effectively sealed into the fuel rail [ rear end] by the new rigid fuel rail is there any need for the old injector retaining plates ? - could the mounting bolt holes for said retaining plates not be used as mounting points for 3 fuel rail retaining brackets? these would then have dual function- keeping the injectors in place and sealing on the fuel rail? Or is that too easy?

Space is very tight - we are going to have to move the throttle bar linkage visible in the photo below about 1cm to create space for the return pipe.

I take it the 2 large jubilee type clamps round the outer/inner inlet manifold arms are to locate that heat shield between the inlet/fuel rail and exhaust manifolds? Looking forward to the "wiring"

I take it the 2 large jubilee type clamps round the outer/inner inlet manifold arms are to locate that heat shield between the inlet/fuel rail and exhaust manifolds? Looking forward to the "wiring"

We use essential cookies to make this site work, and optional cookies to enhance your experience.