Oh yes, just proving to be a pain to upload (photobucket has become impossible). I also forgot my camera one day as the loom work was starting.

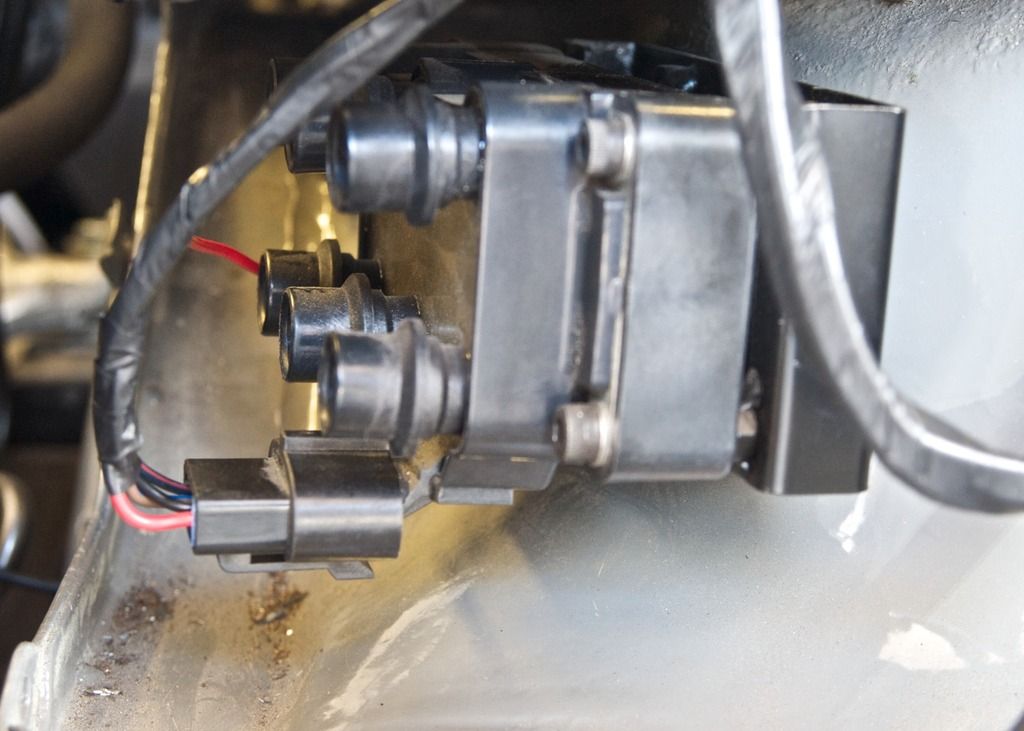

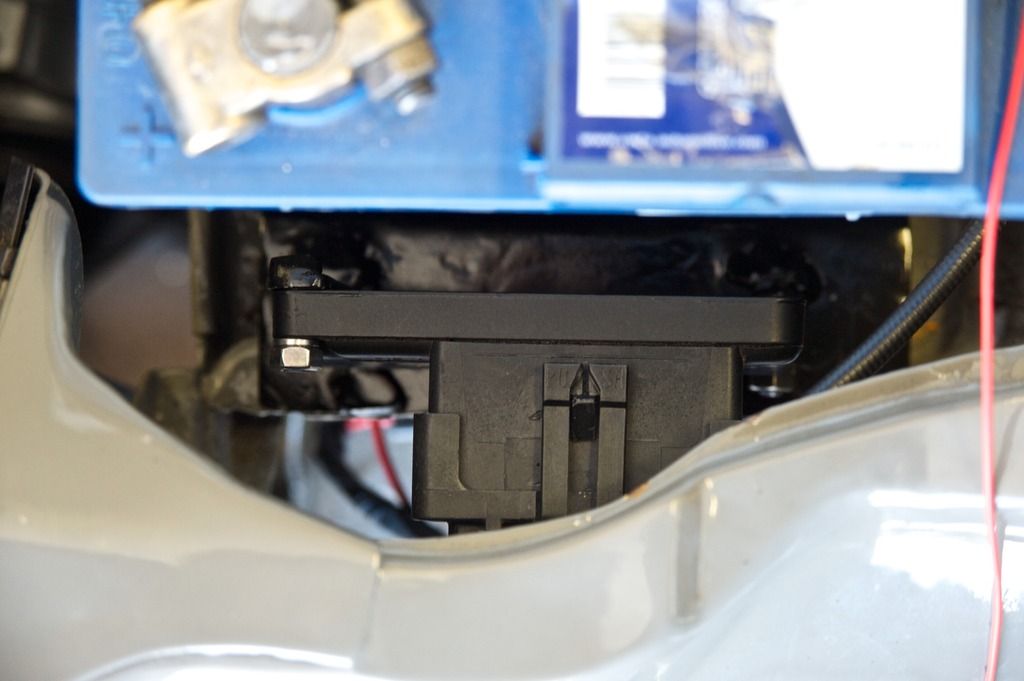

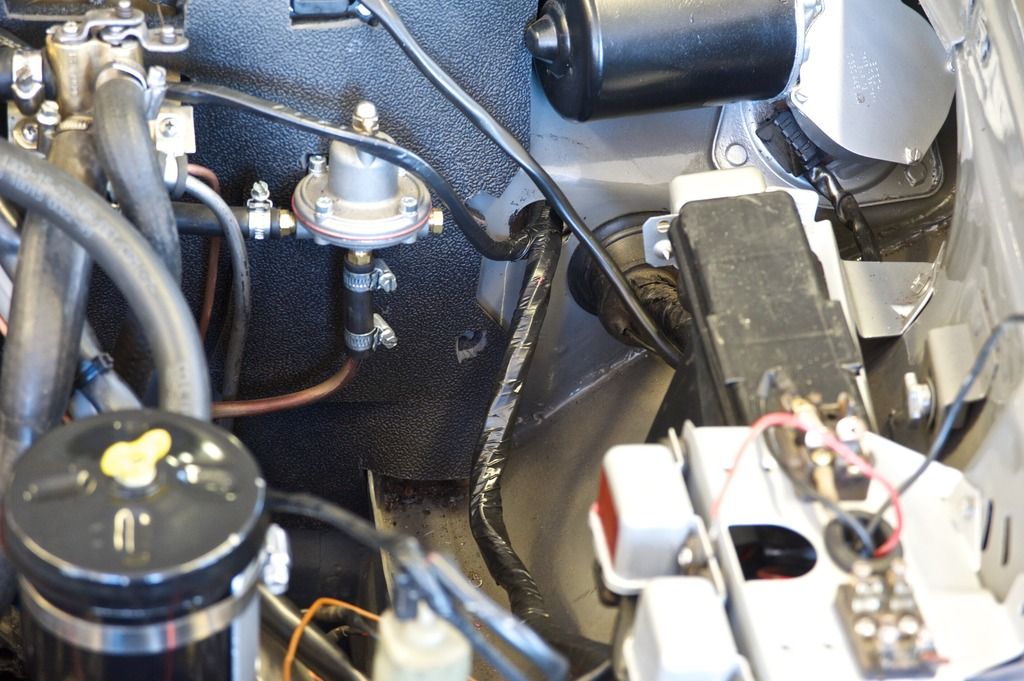

ECU to EDIS controller to coilpacks now wired in and all mounted on brackets

The EDIS controller bracket is attached to the top of the battery plate at the front, and the coilpacks underneath. Next job the HT leads.

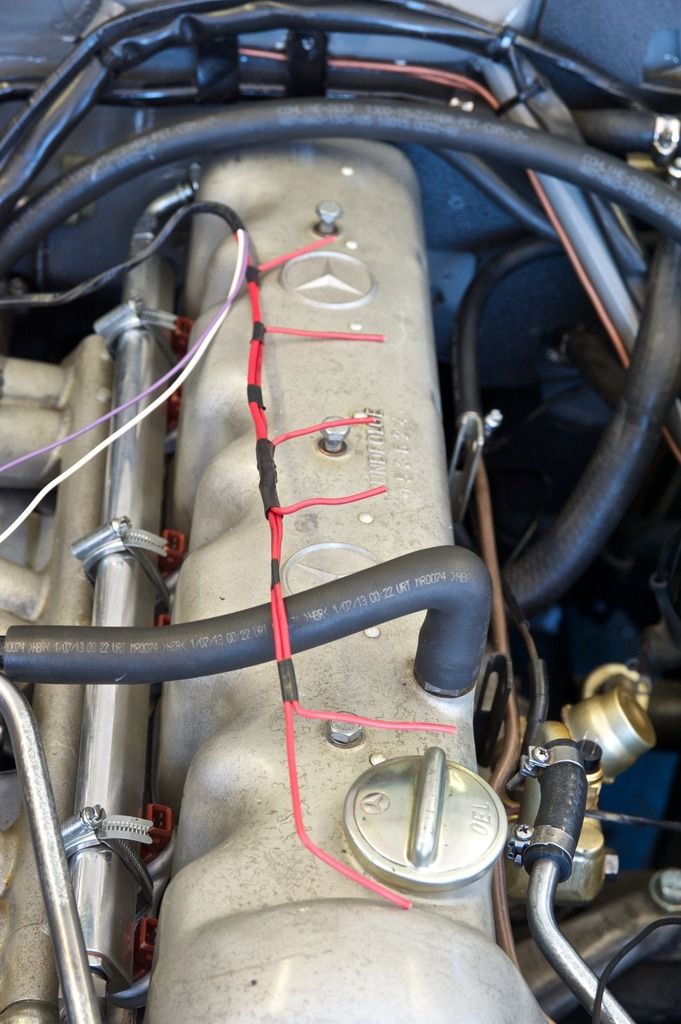

Power leads to injectors.

Soldering the earth connections for injector bank A (they earth to the ECU)

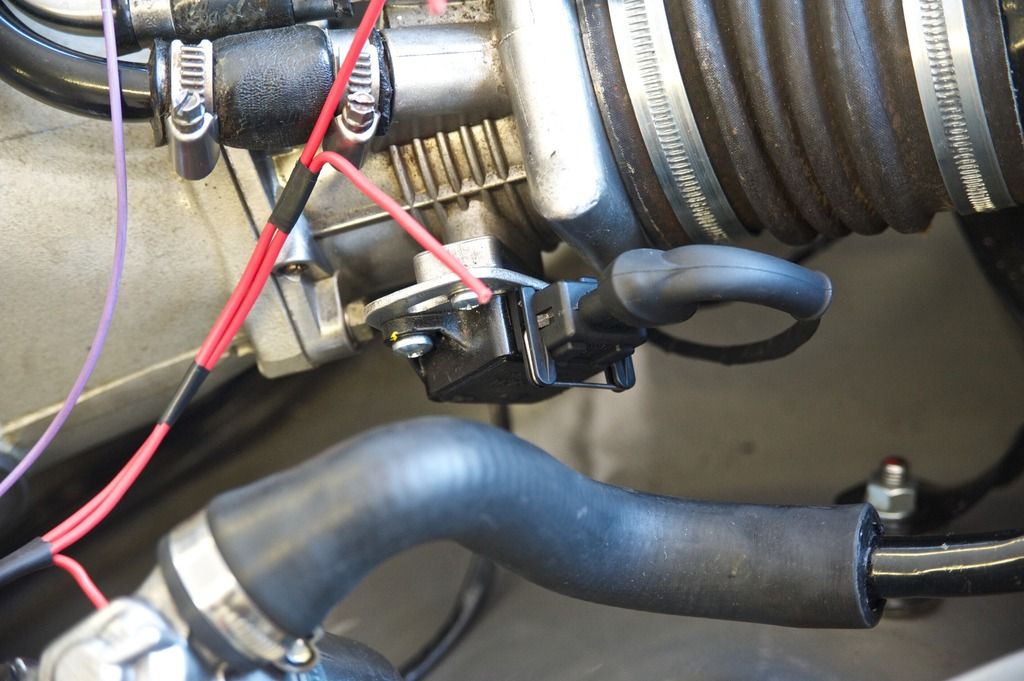

TPS connector now done (as is Air intake sensor).

Main MS loom going through the bulkhead using the old DJet hole

ECU bracket (under dashboard by N/S bulkhead) - the orientation enables the loom to go through the bulkhead easily but lets the USB connection face the cockpit.

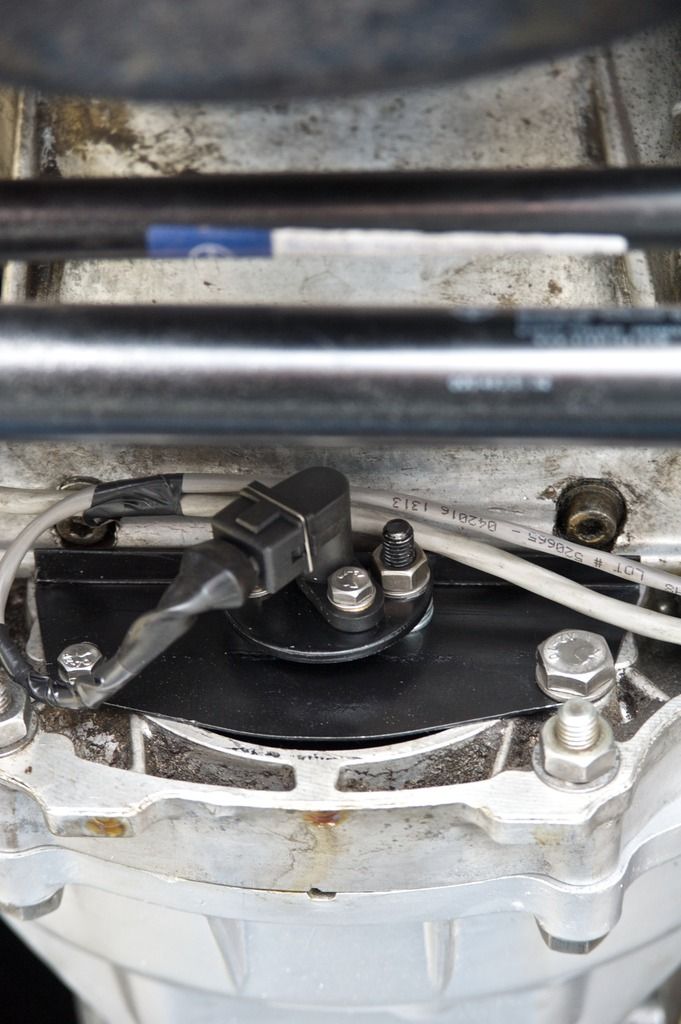

Not shown but the CPS is wired into the EDIS controller with shielded cable, as is the SAW cable to the ECU. I now have 29metres left over (minimum order of shielded cable 100ft!).

The idle control valve requires quite a large power resistor (50w 25ohm) for grounding it so I found them on sale in the UK for not much but you needed to order a 1000, so one is on its way from the US.

I fully expect all the loom to be finished tomorrow. Sadly the existing wiring is incomplete in a lot of places and proving a bit of a pain, but we will get there.