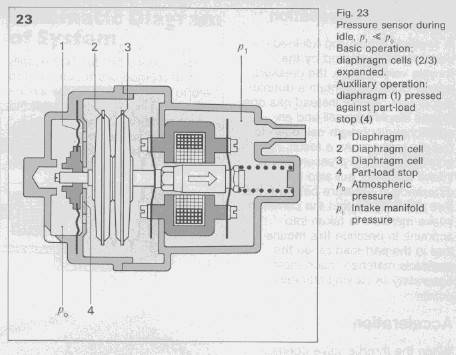

What I liked was the marriage of the mechanical and electronic via the MPS sensor. Altho the cross sectional diagram of the MPS I posted doesn't really help give the whole picture.

The underlying principle of the

linear variable transformer which is an integral part of the MPS is perhaps easier to understand via this diagram

in which a signal in the primary coil is induced in the secondary coil in a way that reflects the position of a moveable core.

The MPS measures the engine load by sensing the manifold pressure. In modern systems based on FI manifold pressure, pressure measurement is Performed by inexpensive, simple, and reliable solid-state sensors. At the time of the development of the D-Jetronic system (mid-1960's), "dry" sensors were nearly 30 years in the future. Precision electrical pressure sensors of the time were based on Linear Variable Transformer (LVT). The LVT used in the MPS is a very reliable device - failures of the MPS; generally are due a mechanical failures of the aneroid cells[ under vacuum when manufactured ] and diaphragm in the unit, largely due to metal fatigue. Essentially LVT's offer infinite resolution, fast linear response, and resistance in a harsh environment. Today's solid state sensors offer most of the same advantages but are are tougher and simpler to interface into electronic systems like the Megasquirt.

[The standard method used with an LVT for displacement measurements and apply is a reference sine wave to the input and measure the amplitude of the sine wave output, Which Varies linearly with displacement across most of the range of the device.]

Bosch, however, did not use this standard method. Instead, a pressure-sensing circuit loop directs a current through the primary coil

which decays at a rate dependent on the armature position, and correspondingly by, the manifold pressure. The induced current in the secondary holds the output of the circuit on until the current decays below a threshold value, generating the basic injection pulse.

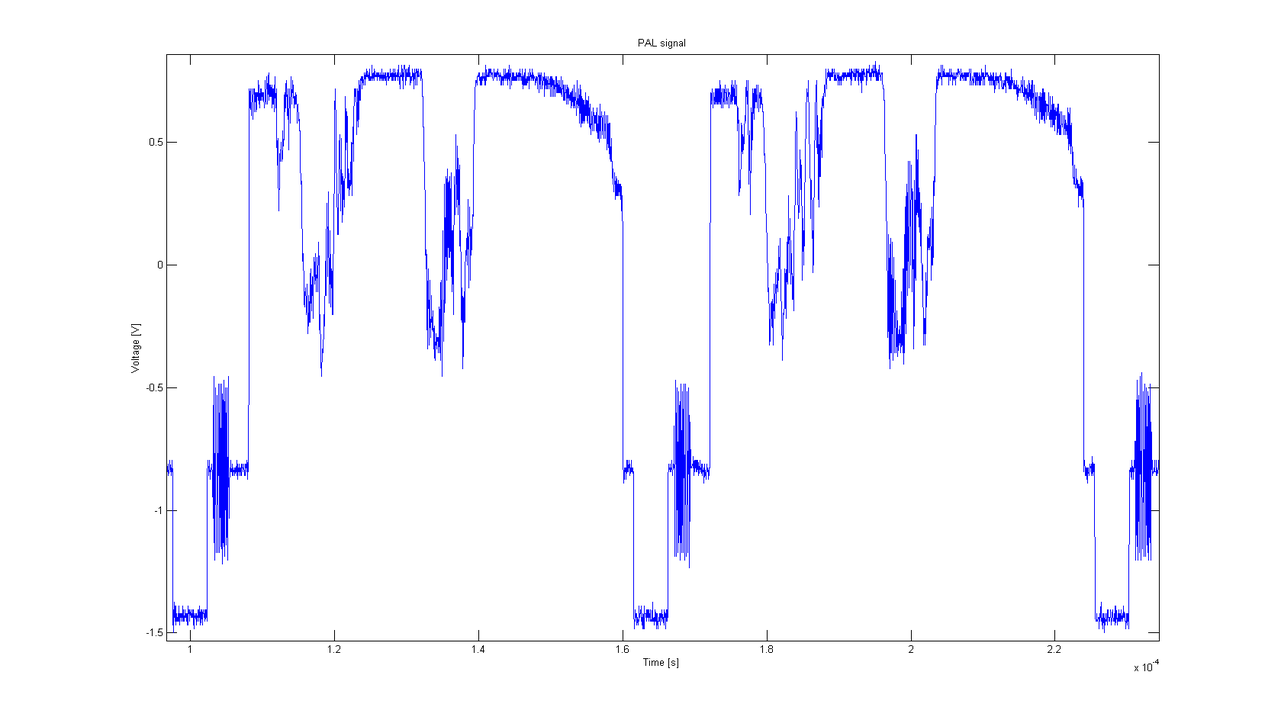

Here are the waveforms and illustrates how the increased primary decay due to the mechanical armature displacement via the aneroid cell deflection induced by manifold vacuum depression widens the fuel injection pulse.

1.Basic injection pulse output of the PL - ground is 1 div down from the top

2.MPS secondary waveform - ground is 4 div down from the top

3. TL trigger waveform - ground is 6 div down from the top

Clever thing is they also incorporated the inlet air temperature sensor resistance in the circuitry since this compensated for any change in charge air density.

Explanation mainly from Paul B. Anders excellent treatise on the Porsche D-jetronic system.

I'm going to have a lie down now.