Jeez .... it's been a busy month that's for sure!

We have just about finished our monster 130 miles house move with 3 young boys. The car has been storming along, the old girl has soaked up everything asked from her except for 1 major disaster all has been well!

Now let's get to the major disaster.....

Yet another issue with the ac system! This time in the form of sudden and catastrophic failure of the original fitment ac compressor

This is a long saga that took above a week to source the correct parts, this is mainly due to the fact that this car is "special" in many areas including it seems, the ac components!

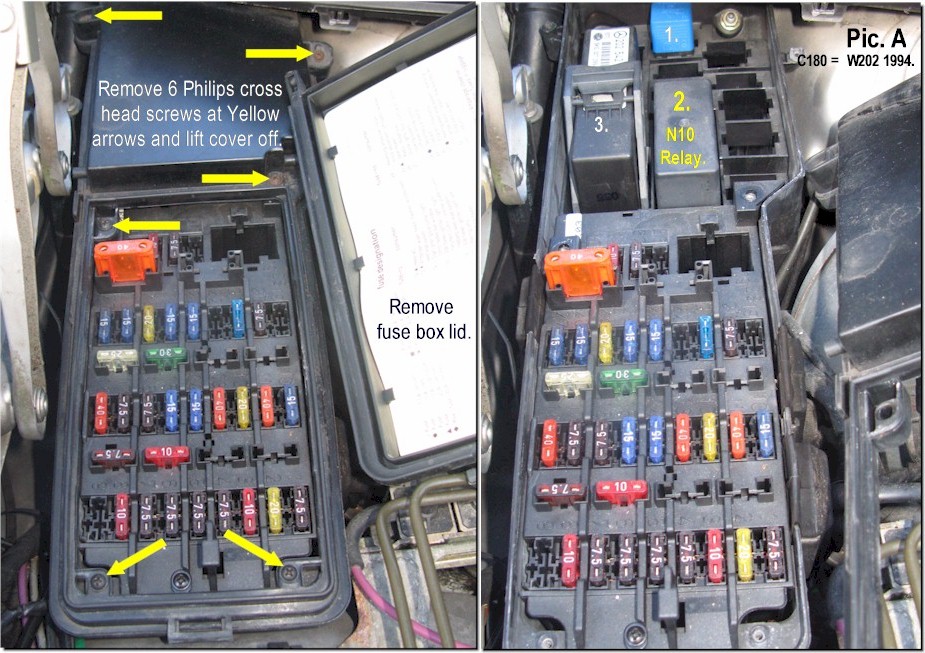

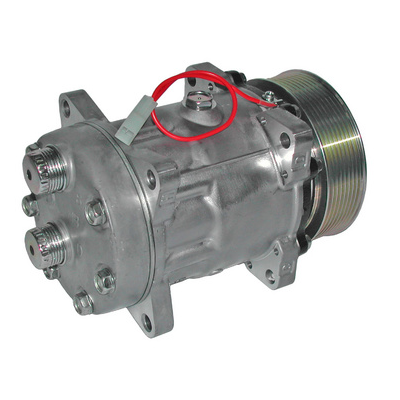

This is what you are all most likely used to seeing fitted to the W202 for the ac compressor...

Now this was the first challenge for me! My car doesn't have this kind of compressor at all. In fact the unit fitted to my car was a Sanden SD7H15 with 4x mount bolts that run front to back.... not side to side as normal.

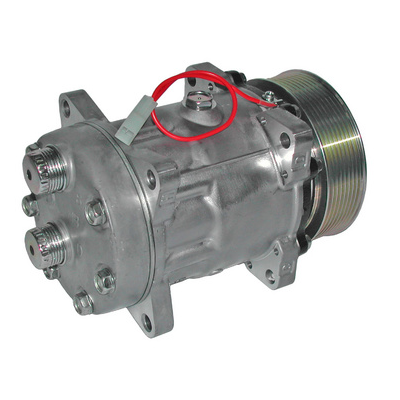

My compressor looks like this....

Eurocarparts at Mansfield were excellent with the sourcing of this compressor and we went through ordering around 6 units before we got the right one!

Sure the one supplied is an 8 rib pulley.... but my car uses a 6 rib belt so it's all good.

The receiver dryer was even more of a pain in the butt. 4 separate variations listed for the w202 were ordered, all were wrong!

This is the type and design that kept arriving and are listed for the car....

The unit fitted to my car (and original at 20 years old) was really hard to pin down! eBay came down good in the end!

Original unit....

I was really surprised to find that this unit is listed as a Peugeot 205/305/309 receiver dryer. When the new part arrived it was a perfect match....

The system is still not up and running yet as we had to remove the backplate/head from the old compressor to remove the unit from the car! The unions were so damn tight onto the compressor that we very nearly tore an engine mount trying to free them off! Once the head was removed from the compressor, we got a hacksaw and cut through the fittings on the head rather than damage the lines....

The bits of the head are still firmly in the unions, we have tried heat, cold and even brute force to release them ..... nothing is working!

It's the last piece of the puzzle before it can be regassed and oiled

It's not been a cheap fix so far either ....

£240 for the replacement compressor (brand new and hard to find)

£18 (or there abouts) for the receiver dryer

£? In endless trips to the factors to collect incorrect parts!

£32 for a new aux drive belt

+ the price that the last bits are going to be to get sorted.

M.O.T is due on the 27th May and it's looking possible that a full exhaust will be required too. Hardly a surprise really as it still has the 20 year old original fitted.... I'm thinking maybe stainless and tailored for quietness is the way that I want to go there (it will actually be cheaper than a full standard system).

Still love the car to bits! Still have the same love that I had for it when I first got it.

And this afternoon, me and my dad had the pleasure* of replacing the front arb bushes and drop links on his W210 2.4 E240 (I should really get a thread started on that one).

Oh and before I totally forget...

As we had the old compressor in bits from removal. I thought it wise to check some of the internals to see what the heck happened.....

This is a broad shot of the surface of the 7 pistons that are inside the SD7H15

Now to highlight the first of the issues, this is what the piston crowns 'should' look like.

3 of the pistons looked like this....

When I turned my attention to the reed valve block that sits between the pistons and the pump head.

It wasn't immediately obvious that there was an issue here....

If you look at the 2 at the top of the picture, 1 is missing entirely and the other is displaced because it's snapped!

From the other side it was obvious there was an issue, this is what you see when you first remove the head....

I have no idea of what caused this internal damage. But this was accompanied by massive play on the compressor pulley! The pulley had so much play in it that the outer rib on the aux belt was ripped apart..... the noise was akin to dumping about 100 ball bearings into the engine, even with the ac turned off!

So there you are guys my first update in a while and it has been 'interesting'