TEST 2 - Tuning Box - Dyno

This specific tuning box requires interaction with three sensors. MAP, boost and CAM sensor. Via these sensors it would be technically possible (depending on car and tuning box) to adjust boost, ignition and possibly fueling (if the ECU is Manifold Absolute Pressure based (speed density being used) rather than Mass Air Flow based for airflow calculations).

As already highlighted previously, tuning boxes can be quickly fitted - 15 mins will see the job done. All you need is the ability to read some very simple instructions. You won’t even need to get your hands dirty!

So… can 15mins pulling some connectors apart and reconnecting with the tuning box in place, really yield any positive results? Let’s find out.

Summary of Spec

Summary of Spec

MY14 A45 AMG

Litchfield Tuning Box

Fuel - VPower Nitro (99 oct)

TEST 2 figure achieved was 406.4bhp & 404.8lbft @ the flywheel

Test 2 +29.9bhp +70lbft (peak) over Baseline

Test 2 +8% bhp +21% lbft (peak) over Baseline

This is where this all gets really interesting and we look into what this graph really informs us of.

With the tuning box connected we have seen some good gains…. with the eye opening part being around the torque increases, which are pretty awesome in reality. If you look at the torque curve you see it still retains that “table top” look of the standard set-up (albeit slightly falling away past 5k, but still in excess of the standard torque levels even past 6k), which should equate to a very strong increase on the road, in respect of acceleration.

At this point we need to move away from peak figures in isolation….. they only tell part of the story.

Based on these peak figures attained, I appear to be underpowered (although the torque gains are pretty huge) compared to other tuning box “graphs”. Let’s delve a bit deeper….. and then see what these “numbers” mean in the real world - because that’s where it counts.

All runs on the dyno were DET free, which was also double checked on the road afterwards.

The maps that I have tested are the same ones that will be included as part of the final consumer product. Not maps that have been “cranked up” just for my benefit.

TEST 1 vs TEST 2

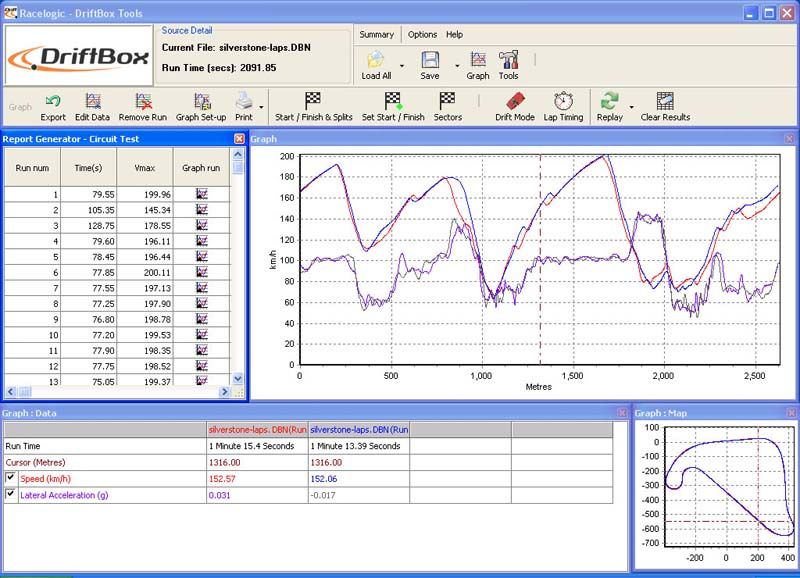

For the above graph I have literally overlaid one with another, so hence some of the blurring on text.

Now we can start to evaluate the increased power/torque difference across the whole of the rev range.

One thing you can quickly tell by looking at a power graph is potentially how “clean” the map is being seen by the ECU and how the engine is reacting. You may notice that the power curve with the tuning box is smooth, with no sudden dips in power. The slight dips you can see in the torque curve (on the tuning box run) follows the same kind of minor dips as the standard run, so in reality, nothing to worry about there.

What is clearly evident is the substantial increase in torque from 1800rpm, all the way through to 6k. From 3-5k we’re seeing in excess of over 75lbft in places…… that’s some serious torque increase in anyones book. As a side note, MAHA dynos have a reputation for under reading on torque - I actually prefer to think MAHA’s are just “more” accurate. We can also see far greater increases in power than the peak power figure increase suggests. Power is increased by over +70bhp in places. In fact the tuning box is delivering an increase in both power and torque all the way through the rev range.

This is why it’s REALLY important to look at the area below the lines, rather than peak figures in isolation.

If I’m being honest I was pretty shocked at the breadth of increases shown, for a 2ltr engine utilising “just” a tuning box.

For a road car, a wide torque band is king in my opinion. We’ll see how this actually translates to real world performance later on, but the dyno graph suggests that the increases in road performance are going to be substantial from this stage of tuning.

So….. what’s changed to enable this increase?

TEST 2 Boost

Unfortunately I’m unable to overlay the two boost graphs (before and after) as the scaling (for boost) of these two graphs is different (sorry - that was an oversight by me), but it’ sort of irrelevant. Since the boost is being read from the ECU, the tuning box is doing it’s “thing” between the ECU and sensors, which in essence means the ECU is seeing the same boost as before (when standard). There are very slight differences in the profile with the tuning box, but nothing that would ever relate to the real power increases clearly seen.

The boost plot with the tuning box is more or less the same “profile” as the standard run.

Although the graph does not show it (the only way I’ll know this for sure, is by logging boost another way - which I’ll come back and do), I don’t like to assume stuff without getting data, but I’d be very surprised if the tuning box is not increasing boost levels….. in fact I’d be amazed, so it’s probably safe to make the assumption that boost is being increased across the rev range.

TEST 2 Ignition Plot

There’s a similar thing going on with the ignition seen by the ECU, although it does appear that Ignition has been reduced by the ECU in places. I can’t be 100% sure what is going on as I need more logging facilities (to come in the future). It would be quite reasonable to expect ignition advance to be reduced, assuming that boost has increased. It’s always a game of finding the best mix of boost and ignition, to achieve the best mix of power and driveability. You’ll be amazed at the difference an ignition heavy map vs a boost heavy map, has on certain elements of driveability.

Whilst this next graph is quite hard to work out which line is associated to which test (1 or 2), if you refer back to the master graphs, you’ll be able to work it out. Here is an overlay between the two ignition plots:

TEST 2 AFR Plot

TEST 2 AFR Plot

This is where we can now start to show some fuelling data, to determine how the ECU’s fuelling strategy is coping with the increase in boost and changes in ignition…… this is a very important area.

The A45 ECU utilises something called a “Closed Loop” strategy. Simplistically, this means this ECU can “self tune” itself, within a certain level of tolerance, for changes it see’s (via the various sensors) that require some adjustment. One of these areas could be fuelling requirements.

As previously mentioned, the A45 has a pseudo wideband lambda sensor just prior to the CAT. With this sensor, it enables the ECU to monitor the air/fuel ratio (AFR) of the exhaust gases. If you (for instance) introduce more air into the combustion chamber, without adding more fuel, you’ll end up with a leaner AFR. This could potentially mean you’ll not supplying enough fuel and you’ll experience DET (losing power) and possibly damage your engine. This is only one example for context.

This type of ECU functionality can work really well with an appropriately set-up tuning box. Which ultimately means that the ECU is still able to control key aspects.

Let’s see what the ECU is doing about the fuelling (we’ll jump straight to an overlaid graph).

As you can see from the two graphs overlaid, they are pretty much identical. The Closed Loop system on the A45 ECU has adapted well to the changes made, and the power that has been gained.

You can’t “safely” rely on the Closed Loop system indefinitely, without properly remapping the ECU tables, to account for further mods. How far we can safely go without accessing the ECU map directly, time will tell as I complete further tests. At this level of tune though, it looks absolutely fine with this specific tuning box/map.

Additionally, when we start properly tuning this car via the ECU, we’ll be modifying the downpipe to accept a proper wideband sensor that will be used whilst mapping. This will ensure we get precise AFR readings (to map to). You shouldn’t use the standard sensor already installed, for mapping, as the results won’t be accurate enough. If you remove the CAT from the exhaust, it’s possible to insert a wideband in the tailpipe, but having one located in the downpipe is best (closest to the turbo as possible).

Whilst all of this data is interesting, how does this all really relate to the real world…… on the tarmac.

TEST 2 - Tuning Box - Road

I appreciate this immediate next bit will be subjective, but don’t worry - we’ll be discussing some objective data in a short while.

With my experience of tuned 2ltr turbocharged engines, I’ve never previously really “felt” a major difference on the road after an initial Stage 1 remap. Yes, they felt quicker, but not night and day. The A45 was somewhat different.

I was in COMFORT mode setting on the gearbox in second gear and I dabbed the throttle. **** me that felt good! You might be rolling your eyes, but the get up and go was instant and strong….. even in COMFORT mode. It just felt awesome. I just started laughing to myself.

I then took the car down a twisty B road and banged it into MANUAL and gave it a workout. The engine performance really was night and day against the standard set-up. The mid-range was so much stronger now, and it just pulled so hard. Looking at the before and after graph, you can clearly see that extra torque from the get go…… that is what translated to the awesome shove I was feeling……. which kept going to the redline.

It’s probably worth me stating that I’ve only just stepped out of a 500bhp Subaru, and whilst the A45 is not as quick (you wouldn’t expect it to be), this A45 is now way more urgent lowdown and more driveable. For the first time I could actually feel that “shove”, that is normally associated with a tuned turbo car. But this “shove” was now instant….. not waiting for the turbo to come on song. It was there as soon as I hit the throttle….. it felt mega and exactly what you want for a road car. The standard set-up feels very linear and sedate by comparison.

It really did put a smile on my face and 100% backed up the new torque figures this car now has.

For a bit of fun (and because I have the data from the same make of Rolling Road), I thought I would overlay a graph from my previous Subaru STI, when it was part way through it’s project development, to see how the A45 in it’s current state of tune compares.

Japanese STI Impreza with the following mods:

2ltr OEM engine

Remapped ECU

VPower 99oct fuel

Development Billet wheel twinscroll turbo

Aftermarket Front Mount Intercooler

Aftermarket induction kit

800cc aftermarket injectors

Uprated fuel pump

Uprated boost controller

Peak figures of 425bhp/380lbft (at the time of this graph).

So, vs a standard A45 with just a tuning box, which one will have a better graph and may look like it’s going to be quicker on the road?

Please forgive the issue I had with the rpm scaling. The BHP and Torque scaling is 100% aligned, and if I managed to actually get the STI rpm scaling correct, it would make the A45 graph look even better!

Just look at how much more torque and power there is from 2k way past 5k. There is 180lbft of difference (in the A45’s favour) in places, from a graph on the STI that says it has more peak BHP!! I’m sorry to the Scooby boys, but even at this basic level of tune, on the road, the A45 looks pretty awesome. I’m going to get a slagging for this off my Subaru mates (sorry guys!).

If you couple this data with the fact that the A45 has an ultra quick DSG type gearbox, and with the Haldex system, is losing less power to the wheels than a Subaru transmission does….. not sure where the Impreza would be.

This again, is another reason why you should NEVER just look at peak figures!!

OK, so we’ve had a bit of fun with comparing data….. let’s get down to some black and white performance data, to see what the power graph of the tuned A45 really means!

TEST 2 - Tuning Box - VBOX Performance Results

Most of you are aware what other VBOX results for other A45 tuning boxes are achieving. Let’s see what this one does.

I haven’t collected many logs due to time and pretty poor weather conditions in the UK over the past couple of weeks. That’s the way it is, and whilst I expect these results to improve with better conditions, they currently provide some keen context.

It is very important that you appreciate the context of some of these results provided. I’d urge you not to take some of the figures without appreciating the context of the entire log. You’ll understand why as you read through this section.

Getting really **** about things (you must be starting to “get me” now), my car is on 19” wheels and has the full aero kit. This ultimately means it’s the worst configuration (out of the options list) to get the ultimate straight line performance figures available. You may only be talking 1/10th of a disadvantage, but it all adds up boys! Obviously the 18” and non-aero models are quicker! lol

One last thing is that the VBOX screen only displays times to 1/10th accuracy. You need to use the Racelogic Performance software to interrogate the logs, to ascertain absolute accuracy. If you don’t do this, you can find that certain information from the VBOX screen can be misleading. Another community member also pointed out recently, that using the “measure” function within the software is the truest statement of times. I have found this absolutely factual, and can result in actual times being up to .08s more accurate. Sounds like we’re splitting hairs here, but this can make a difference on the 10ths, when working out times between certain MPH ranges - so it is relevant as far as I’m concerned.

I’ve already released some information across the forums on times attained. However, I’ve had to recalculate all times based on me now using the “measure” function. This has increased some of the times by up to 0.1s. Just so you know.

None of this data includes any 1 foot roll-out, so this is accurate with nothing applied to make the figures look better than they really are.

Results without log file available

Unfortunately when I completed initial 0-60mph logs, it appears that the VBOX/memory card was not logging results. I had updated the firmware on the VBOX prior to these initial runs, and I don’t know whether this caused the problem. When I found this out, a simple reformat of the memory card resolved the logging issue - so just be aware when you do any firmware update, reformat your memory card at the same time.

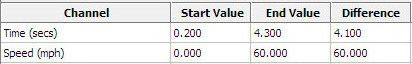

I basically did two runs. The one in the day achieved a 0-60mph of 3.7s. Because I knew I was going to do another run later that evening, I never bothered taking a photo (idiot!).

That evening I completed another run and achieved a 3.8s to 60mph. It was 2degs ambient temperature, so the road surface didn’t provide perfect traction.

Results with log file available

Results with log file available

I was presented (by chance) a 20 minute window between booked sessions, to run some tests at a closed facility. Unfortunately (yes, you’ve guessed it) conditions were not very good. It was cold and wet, but I had to make the most of it.

I effectively managed one semi decent pull, with the other ones, being totally trash….. traction was quite an issue and I was concentrating on getting the launch good, which never really happened. I was running out of time, so I did one last run, taking the A45 up to a 1/4m distance (wish I had done it up to and past 130mph now - you live and learn).

A word of warning. I would not suggest you complete launches under poor traction conditions. Traction was that bad during these tests that the centre display stated the 4Matic system was unavailable. This was after the front axle was tramping really bad upon one specific start, I then heard quite a bang, which would have been when the front must have bounced and the tyres snagged traction again. I did think I had bust something, but after a drive for 5mins and a couple of ignition resets, everything was back to normal. Phew!

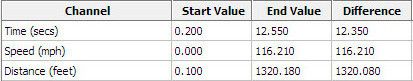

On the run that I did with the best start I obtained (which was pretty awful), we saw the following:

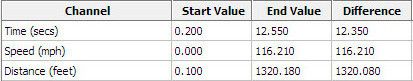

0-60mph : 4.10s (lol)

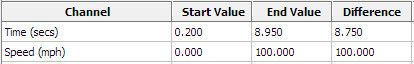

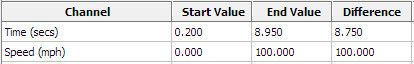

0-100mph: 8.75s

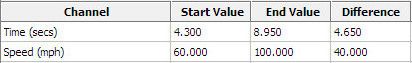

60-100mph: 4.65s

¼ Mile: 12.35s @ 116.21mph

Considering the 0-60mph sprint time, the 0-100mph and ¼ Mile times are pretty impressive for this level of tuning. Read below for the context to support that statement (remember it’s all about context). The 60-100mph tells you the REAL performance potential here.

Remember a standard A45 can do the 60mph sprint in 4.2s and the 0-100mph is seen in 10s. That starts to put into context the kind of performance increases we’re really seeing here, once you remove any traction issues. So, if I can achieve a 8.75s to 100mph with a crap 4.1s to 60mph….. care to think what this car could achieve to 100mph with a decent start!?

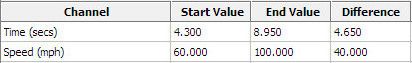

0-117mph

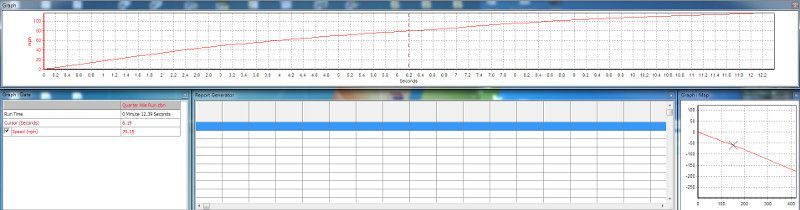

Here is a the VBOX graph of the whole run:

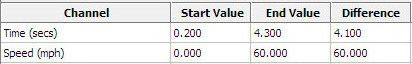

0-60mph

0-60mph

You can see there were problems with traction, which is reflected in the 0-60 time of 4.10s. Not good at all (especially when 3.7s had already been achieved in better conditions).

The 60ft time for this run was 2.27s…… anyone who appreciates this for drag runs, will understand this is a pretty bad figure. Again, due to grip levels and not anything to do with lack of power. With the launch control on these A45’s, this should be much (and clearly has been for other runs I completed) quicker.

0-100mph

Even without a bad 0-60mph sprint this would have been a pretty decent time. With a bad 0-60mph sprint it makes this figure look even better.

1/4m

Now we know this isn’t going to be great, because of the rubbish launch and 0-60 time. Terminal speeds should tell us more though about how this car pulls through the gears.

Getting this sort of time with the 60ft (and 4.1 0-60 time!) it had, is pretty good to be honest. It’s got plenty of potential. I need to complete this all again under better conditions.

So we need to delve deeper into the figures and see how quick the car is post 30mph.

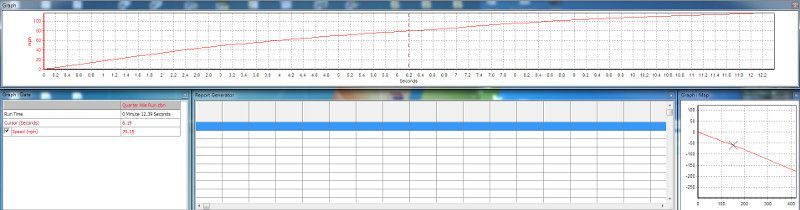

60-100mph

Now were talking. This is a quick time. In fact it’s very quick for the level of power this car is now running. This totally removes traction issues (in this instance) and starts to highlight the real performance that this car now has.

I have completed a number of data comparisons with a couple of other forum members who have other tuning boxes fitted, using data from upwards of 30mph. Suffice to say that (and it may be of no surprise since you’ve seen the 60-100mph time) that this tuning box appears to hold it’s own, very well indeed!

When all said and done we maybe splitting hairs here, and the biggest statement is really how quick these “Tuning Boxed” A45’s are in general, and will surely be in the future with further mods.

Conclusions

Well the use of a tuning box on these cars most certainly work. I’m converted and learnt something else new! The difference in performance is pretty outstanding, and really does bode well for future modifications as part of this project.

Considering this car only has a tuning box and nothing else, the bang for your buck and performance available is truly phenomenal.

One key thing here though is that you really do need to take everything into consideration when judging performance. Don’t use peak figures to make any kind of informed judgement, and make sure you look at all the information available. The key area will always be how the car performs on the road, but using information from accurate dynos and data logging, can ensure you’re heading in the right direction for any informed conclusions.

I’ll let you decide how good you think this tuning box performs. I’ll also let you decide whether you place reported high peak BHP figures, over and above real performance on the black stuff in the real world. We can all get hung up on power figures and 0-whatever times, but it’s thru & in-gear performance, and overall response/driveability that real matter for road cars.

News on the next stage of this project very soon guys!

I'm not suggesting that none of the "known" tuners within this community are not the same. But when its' right to do so, you tend to go on past experiences with people that you already know. P.S. When I was over their last week, walking around the workshop, I was "introduced" to an awesome looking SLS Black Series in for some "mods", parked next to a Ferrari (I didn't take in which one - but it was new lol) in for a twin turbo modfest. Then over the other side of the workshop was a Veyron in for some modifications.

Come on..... who "needs" to modify a Veyron!