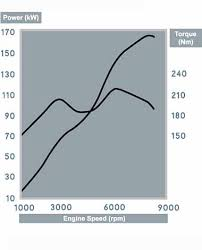

Yep.....and a tuned two stoke pipes job is to try and use the pulses to keep the mixture in the bore rather than going straight out of the exhaust....so it stops loses rather than gaining anything......which they don't do a great job at which is why they are high polluting and thirsty and (without any variable porting YPVS type trickery) pretty peaky too as the exhaust pulses only work within a narrow rev range..

We're only talking about power output here, not considering pollution / fuel consumption.

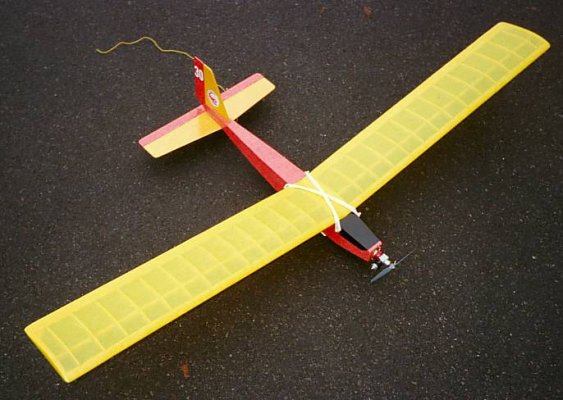

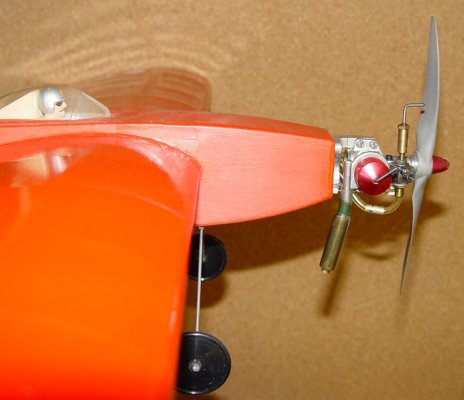

I've never used a 2-stroke bike but I flew r/c aircraft fitted with tuned pipes for many years. These produced more power with a pipe fitted than with an open exhaust (and a lot more than fitted with a simple can silencer). Pipes can certainly be designed to be 'peaky' and only work at a certain rpm, but these are essentially unusable in all bar highly specialised applications (e.g. racing aircraft that run continuously at full throttle only produce full power in the air as the prop unloads and rpm increases to the working range of the pipe). Normally though you'd use a pipe with a much softer/broader rpm range which might give a little less power boost at full bore but would be beneficial at lower ranges too.