Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Mercedes W114 250 Coupe - help!

- Thread starter Charles Morgan

- Start date

Iceviolet

Active Member

I wish my inner wing looked as solid as that!

I have cut firewall insulation previously and I found a sharp, new stanley knife blade did the job well, changing the blade often to avoid dragging the material. Oh and a steady hand! Good luck!

I have cut firewall insulation previously and I found a sharp, new stanley knife blade did the job well, changing the blade often to avoid dragging the material. Oh and a steady hand! Good luck!

Charles Morgan

MB Enthusiast

- Joined

- Feb 2, 2010

- Messages

- 8,206

- Car

- Mercedes 250CE W114, Alfa Romeo GT Coupe 3.2 V6

Easy bits done. A little oversized as is the nature of going round an existing template, but I'll fit it to the car on Friday and do the adjustments before starting on the holes. A very sharp blade and a firm press helped, plus the confidence to make a mistake, as otherwise the edges get very ragged with weak and slow application. Not perfect but it will do.

Charles Morgan

MB Enthusiast

- Joined

- Feb 2, 2010

- Messages

- 8,206

- Car

- Mercedes 250CE W114, Alfa Romeo GT Coupe 3.2 V6

A question posed about the CV boot crimping elsewhere here - help needed!

Charles Morgan

MB Enthusiast

- Joined

- Feb 2, 2010

- Messages

- 8,206

- Car

- Mercedes 250CE W114, Alfa Romeo GT Coupe 3.2 V6

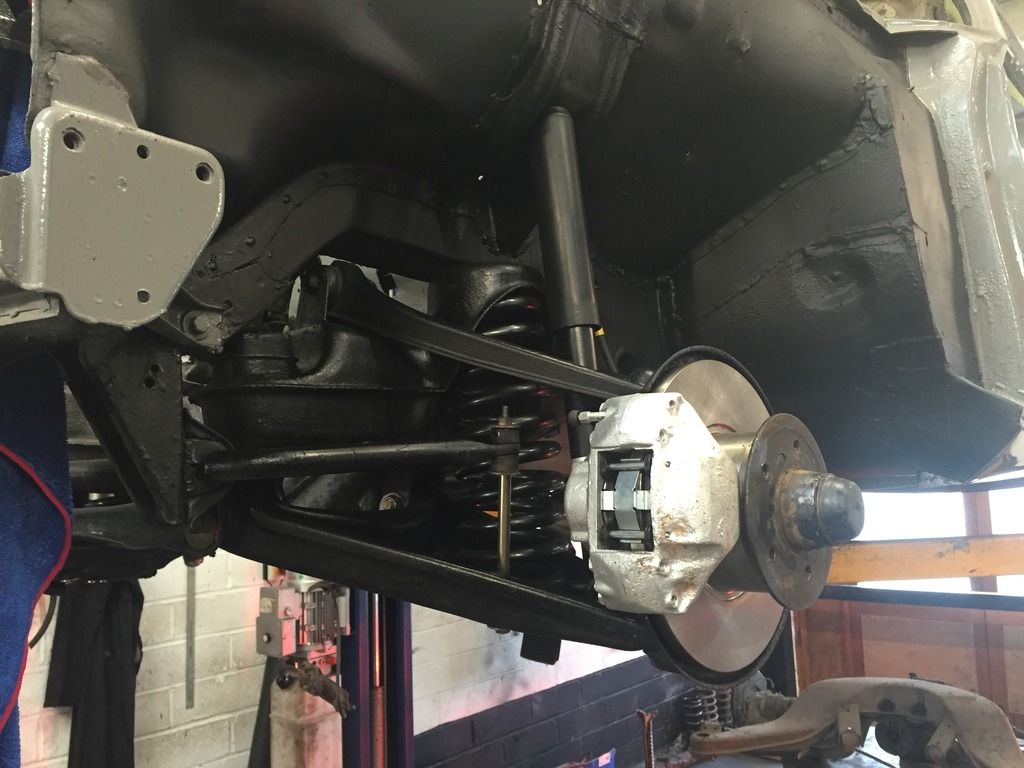

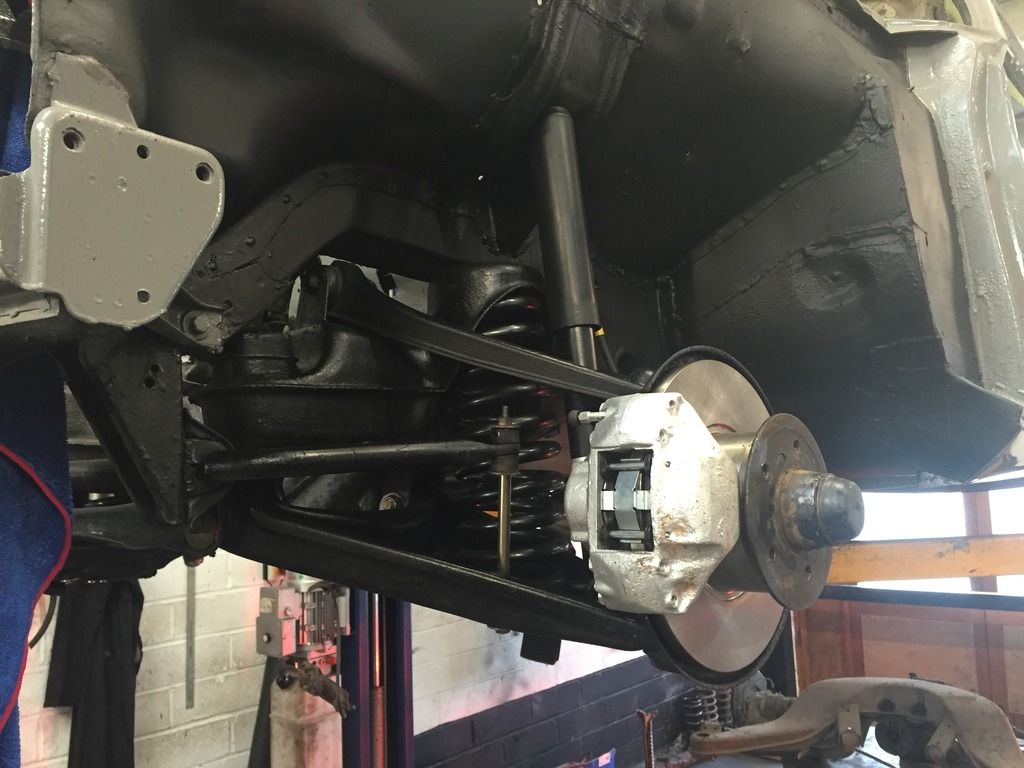

Progress today. John J (JJ) and (Abz) John are working on the car, JJ is doing all the mechanical bits and John is stripping any mess, rust curing, grinding out any poor welds, seam sealing and painting as he goes along. Once done all will be waxoyled. Underseal is a bit flaky in places, some superficial crustiness of metal, but all sound. The work done on the underside and sills of the car 20 years ago before it was laid up clearly has saved the car from the dreaded tin worm. Rear sub-frame out today to do CV joints, shafts, boots, brakes and bushes.

Last edited:

grober

MB Master

A question posed about the CV boot crimping elsewhere here - help needed!

May depend on the design of the crimp? this is a useful video which shows the dedicated tool and the commonly available alternative.

[YOUTUBE]7wEU0JZzac4[/YOUTUBE]

cv boot pliers

https://www.machinemart.co.uk/p/las...GS-040216136&***id=COaz6OfFp8oCFUE_GwodtakPwA

My guess would be to go for the tool recommended by the crimp manufacturer. right tool for the job.

Could someone help me with my CV Boot Clamp Tool. | MIG Welding Forum

Charles Morgan

MB Enthusiast

- Joined

- Feb 2, 2010

- Messages

- 8,206

- Car

- Mercedes 250CE W114, Alfa Romeo GT Coupe 3.2 V6

It's all MB stuff - the problem I believe is joining the two parts of the metal housing, the rubber boots are held on with jubilee clips (all in the MB repair kit).

WDB124066

MB Enthusiast

- Joined

- Apr 17, 2009

- Messages

- 6,170

- Car

- 1996 E320 Sportline Cabriolet x 2

Looks like the part you swage has been swapped around to the other part on the new pieces Charles. If all else fails it looks like you may be able to get away with some precision hammer work to fold the lip on the outboard part over slightly.....

Or, if you can get it in a lathe and put a roller [ball bearings are good for this] in the place of the cutting tool you may just be able to roll it over gently using the toolpost screw...??

Or, if you can get it in a lathe and put a roller [ball bearings are good for this] in the place of the cutting tool you may just be able to roll it over gently using the toolpost screw...??

Last edited:

grober

MB Master

http://mb.bolinko.org/wis/w114/Chassis/35-620.pdf

Another possibility might one of the newer industrial oil resistant adhesives?

Another possibility might one of the newer industrial oil resistant adhesives?

Last edited:

grober

MB Master

dup

Last edited:

Charles Morgan

MB Enthusiast

- Joined

- Feb 2, 2010

- Messages

- 8,206

- Car

- Mercedes 250CE W114, Alfa Romeo GT Coupe 3.2 V6

Someone has been found who will do all the driveshafts work, so often they've gone. I'll post details when I know who they are (and the stuff is fine).

Charles Morgan

MB Enthusiast

- Joined

- Feb 2, 2010

- Messages

- 8,206

- Car

- Mercedes 250CE W114, Alfa Romeo GT Coupe 3.2 V6

A lovely bright sunny winter day, made glorious summer by being driven in C43AMG's delightful CL55K AMG up to CCPS and D&M to look at progress and deliver yet more parts. Unfortunately I left my proper camera at home and the bright directional light meant my iphone photos are not usable. One hole found by the diff bracket (taking bits off is vital), but the subframe is now close to repainted, the rear has been cleaned up and crusty bits removed and painted, while the steering column is being refurbished and generally the progress is spectacular. Alas, I forgot to photograph the wheel trims, bonnet and boot which have all been done and being polished as we were there, but they are all looking really good.

After all my work rustproofing with POR15, it was decided to strip it all off - despite adhering to the instructions, cleaning it with the POR cleaner and priming it with the correct primer, it has started to flake, so off it has come. The clear injunction from Abz John is give no hint that rust can ever take hold again, so no chink in the armour.

Really delighted.

After all my work rustproofing with POR15, it was decided to strip it all off - despite adhering to the instructions, cleaning it with the POR cleaner and priming it with the correct primer, it has started to flake, so off it has come. The clear injunction from Abz John is give no hint that rust can ever take hold again, so no chink in the armour.

Really delighted.

Bellow

Hardcore MB Enthusiast

I'm confused. I got the impression that POR15 was the last word in rustproofing. Why didn't it work and how is the underside to be treated now?

Another question. My natural course of action would have been to sort out all of the underside then paint the body - the thinking being less chance of damage to the paint work while the car is still being worked on. Not how it's been done here. Why so? To give the paint longer to harden before being exposed to the rigours of road use?

Another question. My natural course of action would have been to sort out all of the underside then paint the body - the thinking being less chance of damage to the paint work while the car is still being worked on. Not how it's been done here. Why so? To give the paint longer to harden before being exposed to the rigours of road use?

Charles Morgan

MB Enthusiast

- Joined

- Feb 2, 2010

- Messages

- 8,206

- Car

- Mercedes 250CE W114, Alfa Romeo GT Coupe 3.2 V6

I can only speculate on the reason for the POR15 failure, on perfect surfaces it seems to stick brilliantly, but on the car it seemed to just peel away, so I can only assume it is very sensitive to underlying surface. Really very disappointing, I could understand if incorrectly applied by me, but as I said I followed the instructions to the letter. Abz John described the new regime but I missed out the name of the key products, but it involves 3 coats and one of waxoyl.

The latter - an arbitrary division of labour between the two firms and inexperience on my part.

The latter - an arbitrary division of labour between the two firms and inexperience on my part.

ianrandom

MB Enthusiast

- Joined

- Feb 19, 2010

- Messages

- 1,000

- Car

- 1986 420SE, 1990 420SEC, 1989 2CV6.

I've had that with POR15 before. I hadn't prepared the surface properly I think. It just peeled off.

When it works it's pretty amazing stuff though, rock hard.

When it works it's pretty amazing stuff though, rock hard.

Charles Morgan

MB Enthusiast

- Joined

- Feb 2, 2010

- Messages

- 8,206

- Car

- Mercedes 250CE W114, Alfa Romeo GT Coupe 3.2 V6

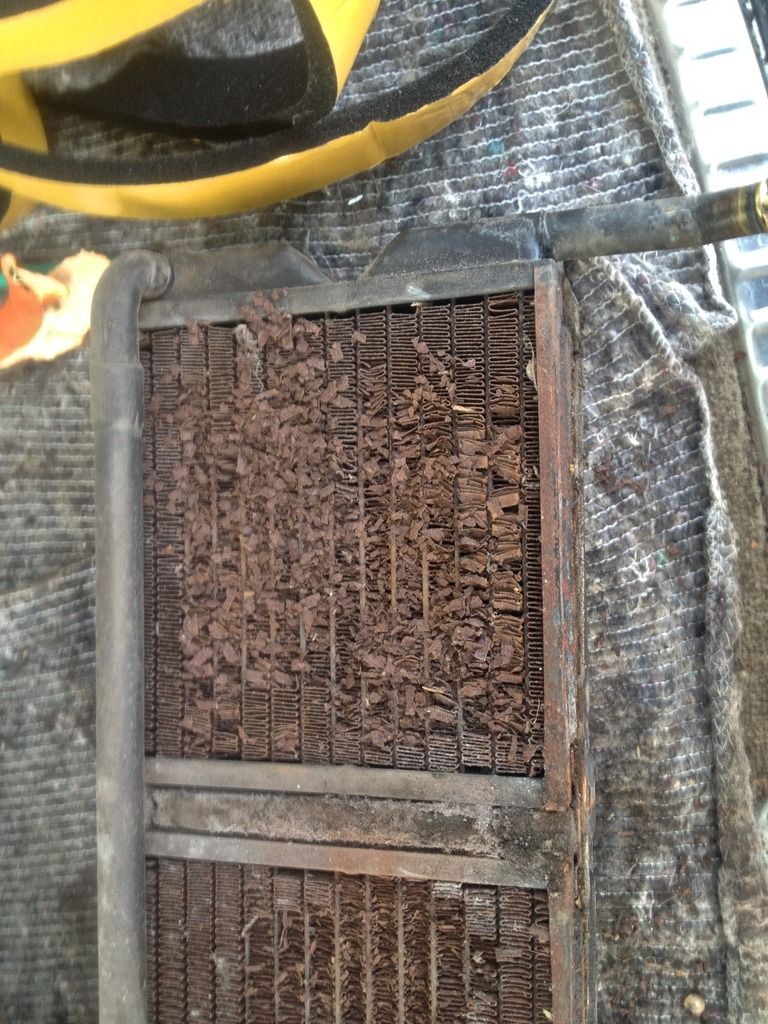

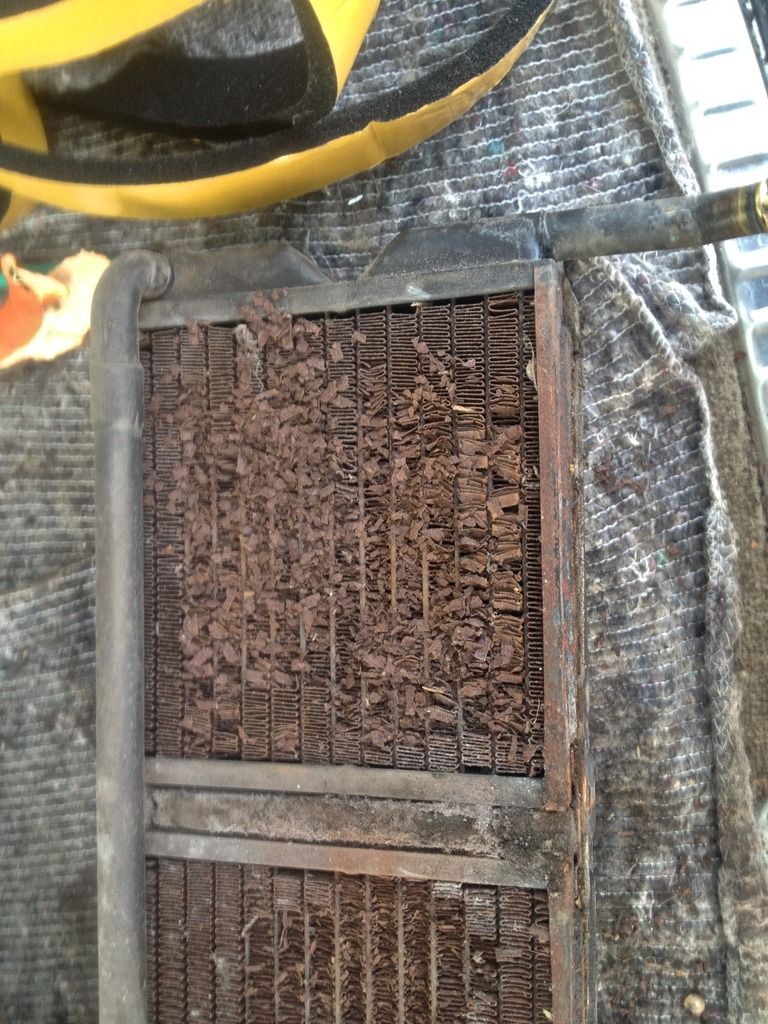

Age and moisture keep taking their toll. Cleaning up the heater matrix today and I touched the metal core - first photo shows how it crumbled to the touch.

Just to show the effect of some gentle pressure on the core - the right hand side was reduced from looking ok to gone in 10 seconds

I think I'll have this re-cored - a second hand one is just too old now to take the risk on.

Just to show the effect of some gentle pressure on the core - the right hand side was reduced from looking ok to gone in 10 seconds

I think I'll have this re-cored - a second hand one is just too old now to take the risk on.

brucemillar

MB Enthusiast

- Joined

- Nov 18, 2010

- Messages

- 8,663

- Car

- C55 AMG Wagon - W124 300te 4matic Wagon - BMW 4.8is X5 E53 - SWB Pajero 3.5 V6 24v

Charles.

I have a chap who does re-cores if required. He does lots of classics.

Sent from my iPhone using MBClub UK

I have a chap who does re-cores if required. He does lots of classics.

Sent from my iPhone using MBClub UK

Charles Morgan

MB Enthusiast

- Joined

- Feb 2, 2010

- Messages

- 8,206

- Car

- Mercedes 250CE W114, Alfa Romeo GT Coupe 3.2 V6

Thanks Bruce - I'll whack it up to A1 radiators in Banbury (just up the road from CCPS) who re-cored my radiator some months ago.

WDB124066

MB Enthusiast

- Joined

- Apr 17, 2009

- Messages

- 6,170

- Car

- 1996 E320 Sportline Cabriolet x 2

You crossed my mind briefly today Charles even if it is slightly newer, quite a handy turn of speed too.

Surprisingly not running a lot of -ve camber.

Almost lost in a world of Porsche.

Surprisingly not running a lot of -ve camber.

Almost lost in a world of Porsche.

Last edited:

Charles Morgan

MB Enthusiast

- Joined

- Feb 2, 2010

- Messages

- 8,206

- Car

- Mercedes 250CE W114, Alfa Romeo GT Coupe 3.2 V6

Porkers are ubiquitous to the point of tedium at every classic event. The 280 was used by AMG as the basis for a decent tune up - bit more compression, re-profiled cam and more fuelling, and it can get to over 200bhp, in a relatively light car.

Good to see someone using it properly!

Good to see someone using it properly!

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)

Similar threads

- Replies

- 90

- Views

- 4K

- Replies

- 4

- Views

- 614