ACID

MB Enthusiast

Hi Guys,

First and foremost i hope you have all had a good Christmas : )

I would like to thank everyone here for their support over the last few years.

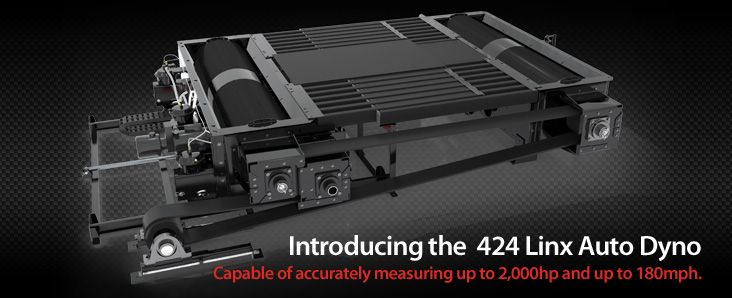

We are happy to announce that we have purchased a New Dyno for our premises at MSL Performance.

As you know there are a lot of tuning companies who don't have a dyno facility on site and its hard to know what you guys are paying for when you get modifications done to your cars. Whether you are getting good value and real world figures for your hard earn't money.

We will be offering before and after dyno figures with print outs.

I have started a build thread for the dyno room and we would like to get as much input from you guys on how we should setup the dyno room.

This project is being supported by Jerry @ Eurocharged by bringing the research and development of new mapping Technology in the UK.

The dyno will be a 4 wheel drive dyno with the capability of 2000bhp.

We will offer a FREE open day to all the member on the Forum.

We Hope to have this project Finished by Feb 2014.

Here is some Dyno Information:

Model 424xLC²

The 424xLC² utilizes a pair of 224xLC's along with an ingenious wheelbase adjustment system, the 424xLC² can handle all the popular AWD vehicles on the road today. Along with offering the precise control from the eddy current load absorption units, the system also eliminates any potential speed bias between the two drums. This virtue is critical on some of the latest computer controlled AWD systems.

Model 424xLC² : Details

Measures up to 2000 + hp and 180mph (Per Drum)

Dynamometer Chassis (drums, shaft, bearings, etc.)

WinPEP7 Software and Hardware to interface (PC, printer, etc. not included)

Auto Tie Down Package (straps, ratchets and hooks)

Ignition Wire Inductive Tachometer Pickup Leads

Anchor Bolts with Level Adjusters

Four Rubber Chocks

Air Actuated Brake System

Remote Software and Brake Control From Driver's Seat

Automatic Conditions Measurement (absolute pressure, air temp, etc.)

Model 424xLC²: Specifications

As with the 224xlc, load tests can be performed including step, sweep and loaded roll on. Closed loop load testing is also available by targeting engine RPM, speed or percentage of load. A simple click of the mouse or keyboard can turn the 424xLC² back into an inertia only dynamometer or into a dual eddy current unit. The torque cell calibration routine takes less than a minute to perform. Each eddy current unit attaches to the roller directly by way of a splined shaft, eliminating issues such as belt slippage or failure while maintaining superior repeatability.

The 424xLC² can be configured for above-ground installation with the use of a four-post lift and all-wheel drive above ground platform assembly or below ground into a pit. Wheelbase is adjustable between 97" and 127" in order to accommodate a wide variety of vehicles.

First and foremost i hope you have all had a good Christmas : )

I would like to thank everyone here for their support over the last few years.

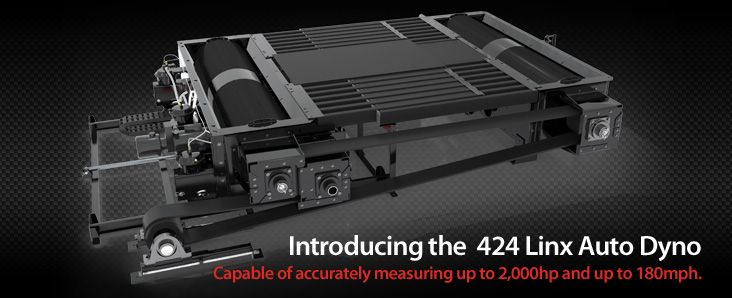

We are happy to announce that we have purchased a New Dyno for our premises at MSL Performance.

As you know there are a lot of tuning companies who don't have a dyno facility on site and its hard to know what you guys are paying for when you get modifications done to your cars. Whether you are getting good value and real world figures for your hard earn't money.

We will be offering before and after dyno figures with print outs.

I have started a build thread for the dyno room and we would like to get as much input from you guys on how we should setup the dyno room.

This project is being supported by Jerry @ Eurocharged by bringing the research and development of new mapping Technology in the UK.

The dyno will be a 4 wheel drive dyno with the capability of 2000bhp.

We will offer a FREE open day to all the member on the Forum.

We Hope to have this project Finished by Feb 2014.

Here is some Dyno Information:

Model 424xLC²

The 424xLC² utilizes a pair of 224xLC's along with an ingenious wheelbase adjustment system, the 424xLC² can handle all the popular AWD vehicles on the road today. Along with offering the precise control from the eddy current load absorption units, the system also eliminates any potential speed bias between the two drums. This virtue is critical on some of the latest computer controlled AWD systems.

Model 424xLC² : Details

Measures up to 2000 + hp and 180mph (Per Drum)

Dynamometer Chassis (drums, shaft, bearings, etc.)

WinPEP7 Software and Hardware to interface (PC, printer, etc. not included)

Auto Tie Down Package (straps, ratchets and hooks)

Ignition Wire Inductive Tachometer Pickup Leads

Anchor Bolts with Level Adjusters

Four Rubber Chocks

Air Actuated Brake System

Remote Software and Brake Control From Driver's Seat

Automatic Conditions Measurement (absolute pressure, air temp, etc.)

Model 424xLC²: Specifications

As with the 224xlc, load tests can be performed including step, sweep and loaded roll on. Closed loop load testing is also available by targeting engine RPM, speed or percentage of load. A simple click of the mouse or keyboard can turn the 424xLC² back into an inertia only dynamometer or into a dual eddy current unit. The torque cell calibration routine takes less than a minute to perform. Each eddy current unit attaches to the roller directly by way of a splined shaft, eliminating issues such as belt slippage or failure while maintaining superior repeatability.

The 424xLC² can be configured for above-ground installation with the use of a four-post lift and all-wheel drive above ground platform assembly or below ground into a pit. Wheelbase is adjustable between 97" and 127" in order to accommodate a wide variety of vehicles.