Need to replace the outer bushing in both spring control arms in the rear.

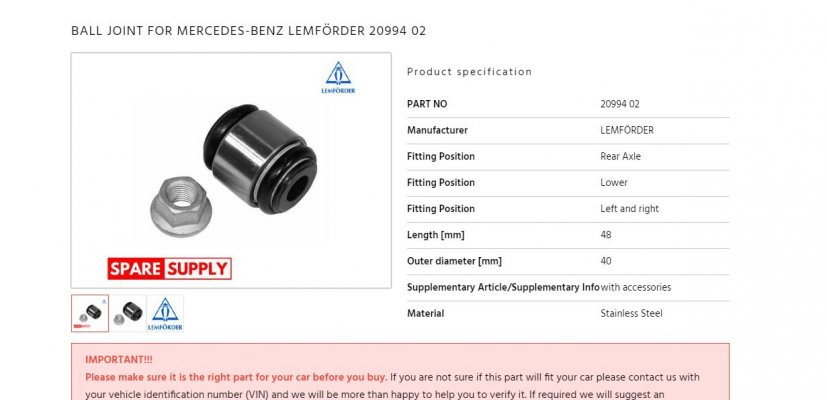

But when I have the control arm loose it looks like it is made of two pieces and that the bushing is not possible to replace. Also the new bushing is 40 mm vs the hole in the arm which is 38 mm.

Is it true that I have to buy two new complete arms?

This is a W211 without Airmatic but with self leveling air springs at the rear axle.

Thanks

Daniel

But when I have the control arm loose it looks like it is made of two pieces and that the bushing is not possible to replace. Also the new bushing is 40 mm vs the hole in the arm which is 38 mm.

Is it true that I have to buy two new complete arms?

This is a W211 without Airmatic but with self leveling air springs at the rear axle.

Thanks

Daniel